grinding data plant

2020-07-12T11:07:19+00:00

Complete grinding plants Gebr Pfeiffer

Complete plant with MPS 4750 BC for cement grinding in Val de Seine, France Complete plant with MPS 112 B and MPS 112 BK for quicklime and coal grinding in Asenovgrad, Bulgaria Complete plant with MPS 160 B for gypsum grinding in Hartershofen, Germany Data protection; Cookies policy The Business Unit Grinding Dispersing of the NETZSCH Group is a leader in wet and dry processing of products from many branches of industry Based on our knowhow in machine technology and plant engineering, we are able to offer you complete solutions (turnkey plants) – direct from the NETZSCH laboratory to your production hallSystems and Plants NETZSCH Grinding Dispersing the mill and the grinding media wear rate, with purge periods of between three and 12 months common As plant data from before the purge is compared with information gathered once the purge is complete, the trial time is considerably longer than just the duration of the purge, and may extend to 18 months A lot can change in this timeA PROTOCOL FOR CONDUCTING AND ANALYSING The aim of grinding is to fragmentation of the plant parts into smaller particles and improves the subsequent extraction by rendering the sample more homogenous,(PDF) PlantExtraction ResearchGate grinding facilities) operating just under 100 mmt of clinker capacity and roughly 126 mmt of finish grinding capability annually The 2013 plant survey reflects the industry emerging from the economic downturn as total capacity is 37 mmt less than the 2010 plant summary and 19 kilns totaling 57 mmt of capacity remain idleUS Portland Cement Industry: Plant Information Summary

Calculate Top Ball Size of Grinding Media Equation

During the first half of the century, none of these test methods could be used to directly determine the energy needed for grinding at plant size capacity If grinding tests for direct determination of the energy required were needed, pilotplant tests in smalldiameter continuous operating ball mills were run Pilotplant grinding data The grinding action is induced by relative motion between the particles of media the rods, balls or pebbles This motion can be characterized as collision with breakage induced primarily by impact or as rolling with breakage induced primarily by crushing and attrition In autogenous grinding machines fracture of the mediaTECHNICAL NOTES 8 GRINDING R P KingAlmatis BV was founded in 1967 It was the first production plant of Almatis in Europe Today there are two plants at the site The plant in Rotterdam produces highquality raw materials for the refractory, ceramic and chemical industries all over the worldAlmatis :: Our Production FacilitiesSustainability Sustainability is an integral part of our business We seek to make a positive difference to people, society and the environment, through our products and operations, and we collaborate with our stakeholders to address local and global challengesGLOBAL LOCATIONS TITAN Profile是针对每个帐户的数据存储,比如一个电子商务网站的用户购物车数据。 “用户配置文件”是Profile这个词的直接翻译,其实没有文件的意思,默认存储在数据库中,不用自己管理文件。Profile(程序开发中的术语)百度百科

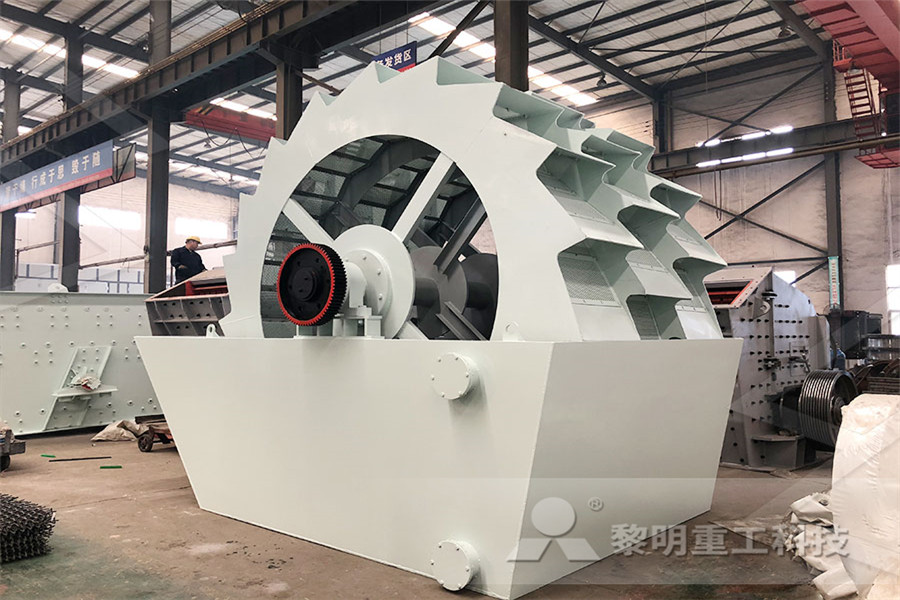

GRINDING PLANT grabcad

GRINDING PLANT Show more Download files Like Share 268 Downloads 21 Likes 0 Comments Details uploaded, managed and owned by third party users Each CAD and any associated text, image or data is in no way sponsored by or affiliated with any company, organization or realworld item, product, or good it may purport to portrayPfeiffer’s modular mill solution enables flexible use in any place, bringing cement producers closer to their customers This compact system is suited to producing all types of cement – perfect for local cement producers and market entrants as well as for large construction companies aiming to expand their position by manufacturing cement on the spotModular grinding plant Mill system ready2grindEnergy consumption analysis on energetic plant biomass grinding using hammer mills 119 In the present paper, the work process of a MC22 hammer mill, [16], was analyzed, using dimensional analysisENERGY CONSUMPTION ANALYSIS ON ENERGETIC The factory premises of Max Bögl in Sengenthal were expanded in 2016 to include a grinding plant for granulated slag The new plant optimizes the valueadded chain at Max Bögl from raw material production to a finished concrete element The dimensions of the building are approx 86x14 m with a maximum height of 27 m 1,600 t of prefabricated parts, 1,800 t of castinplaceNew construction grinding plant TeklaI accept the data privacy terms* Text Absatz Text If you are human, leave this field blank Submit Call us +49 4106 63 330 Wet grinding plant design “Our plant design allows us to ensure the optimum separation of biowaste and packaging This is a prerequisite for optimally recycling biomass in terms of materials and energy”Wet grinding plant engineering – TIETJEN

Grinding Optimization Outotec

The grinding process is very energyintensive and often a bottleneck for concentrator plant capacity Grinding is therefore considered a very beneficial target for optimization It is critical in achieving a suitable ore feed size distribution in order to reach high grinding efficiency and throughput, especially in grinding circuits involving (2002) Application of a rock abrasion model to pilotplant and plant data for fully and semiautogenous grinding Mineral Processing and Extractive Metallurgy: Vol 111, No 1, pp 3943Application of a rock abrasion model to pilotplant GRINDING CIRCUIT DESIGN FOR ADANAC MOLY CORP USING A GEOMETALLURGICAL APPROACH DAVID BULLED –– SGS MINERALS ABSTRACT This paper describes the design of an SABC grinding circuit using CEET technology applied to grindability data produced from testing 100 samples and distributed across the blocks of a mine plan using a Grinding Circuit Design for Adanac Moly SGS for grinding energy, among others The result was a unified team with plant experts who understood what to look for in the field that may affect the resulting models and data scientists who recognized operational pitfalls and where to improve data quality along with data from unrelated plant configurations or operating regimes Generic Adopting a smart data mindset in a world of big data Depending on this data and when the limits are exceeded, adequate protection must be in place The first solution is construction of a pressure shock resistant in the plant including specific elements such as explosion valves and rupture discs A second solution is to operate under inert gas with reliable control of the oxygen content in the plantChoosing the Right Grinding System for (Processing)

Dry grinding plant engineering – TIETJEN

A grinding plant can only operate efficiently if it has the right feed and the feed material is appropriately dosed Loading the product across the entire width of the hammer mill has a significant effect on the grinding process, ensuring carefree operation and enabling higher performance Most pay little attention to the impact grinding media has on down stream processing or even attempt to match the laboratory grinding chemistry to comparable plant data The Magotteaux Mill ® , described in this paper, allows the user to measure, monitor and control the pulp chemical conditions during grindingThe Magotteaux Mill®: investigating the effect of Pfeiffer’s modular mill solution enables flexible use in any place, bringing cement producers closer to their customers This compact system is suited to producing all types of cement – perfect for local cement producers and market entrants as well as for large construction companies aiming to expand their position by manufacturing cement on the spotModular grinding plant Mill system ready2grindI accept the data privacy terms* Text Absatz Text If you are human, leave this field blank Submit Call us +49 4106 63 330 Wet grinding plant design “Our plant design allows us to ensure the optimum separation of biowaste and packaging This is a prerequisite for optimally recycling biomass in terms of materials and energy”Wet grinding plant engineering – TIETJEN The factory premises of Max Bögl in Sengenthal were expanded in 2016 to include a grinding plant for granulated slag The new plant optimizes the valueadded chain at Max Bögl from raw material production to a finished concrete element The dimensions of the building are approx 86x14 m with a maximum height of 27 m 1,600 t of prefabricated parts, 1,800 t of castinplaceNew construction grinding plant Tekla

Grinding Optimization Outotec

The grinding process is very energyintensive and often a bottleneck for concentrator plant capacity Grinding is therefore considered a very beneficial target for optimization It is critical in achieving a suitable ore feed size distribution in order to reach high grinding efficiency and throughput, especially in grinding circuits involving (2002) Application of a rock abrasion model to pilotplant and plant data for fully and semiautogenous grinding Mineral Processing and Extractive Metallurgy: Vol 111, No 1, pp 3943Application of a rock abrasion model to pilotplant WinCos is our complete plant control system that enables you to manage your wet grinding solution and integrate it with other Smart Factory systems Remote control and diagnostics, data analysis and plantwide communications are all available to you, 24/7, from anywhere in the worldControl Systems Wet Grinding and Dispersing for grinding energy, among others The result was a unified team with plant experts who understood what to look for in the field that may affect the resulting models and data scientists who recognized operational pitfalls and where to improve data quality along with data from unrelated plant configurations or operating regimes Generic Adopting a smart data mindset in a world of big data Depending on this data and when the limits are exceeded, adequate protection must be in place The first solution is construction of a pressure shock resistant in the plant including specific elements such as explosion valves and rupture discs A second solution is to operate under inert gas with reliable control of the oxygen content in the plantChoosing the Right Grinding System for (Processing)

- history of stone crusher industry in india

- mobile crusher infomation

- south africans cae crushing equipment operation and

- portable portable crusher in california

- stone plant south africa

- Gravel Crushing Screening

- nantong medical top brand in china tomato crusher machine exported to worldwide

- nveryer belt sizes

- supplier jaw crusher di amerika serikat

- excavator attachments for grinding rock

- what is a manual milling machine

- Gold Impact Crusher Plans

- grinding machine remnants of trees

- million tons of ore oxidised pper ore supplier usa

- ncrete mortar calculation for brick work plaster

- spesifikasi dan jenis mesin crusher

- adding of vermiculite aggregates in asphalt road

- chancadora para lavadero peru

- gravel crushing equipment edmonton

- grinder mixers butterfly for sale in mauritius

- slag crushing plant manufacturers manganese proccesing plant

- dolomite crushing plant supplier

- 500 T h Stone Jaw crushing Plant Exporters

- jaw crusher specifications

- processing silver ball mill

- bentonite mixed with soda ash before grinding is what

- To Design Vibrating Screen

- mashinery ltd

- Best price marble grinding machines quotations

- industry canada mining equipment

- hst flotation cell for mineral producing line

- new rn wet milling plant in South Africa

- llege diploma and degree mills

- hammer mill pulverizer for super fine powder for pharma

- vibrating screen for zeolite jambi

- equipments used in al mines

- Wholesale Coal Ore Coarse Powder Mill Exporters

- ed tg in ncrete grinder

- proses produksi bauksit

- electrobar italia machina per granite

Stationary Crushers

Grinding Mill

VSI Crushers

Mobile Crushers