ncentration of pper oxide ore

2021-01-30T11:01:16+00:00

copper oxide ore concentration mayukhportfolioco

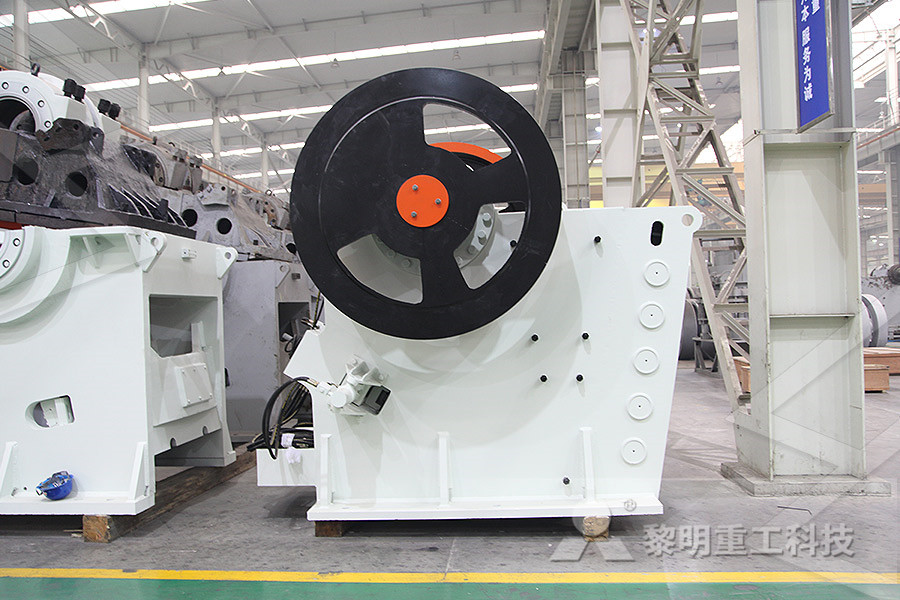

Copper extraction techniques Wikipedia, the free encyclopedia Concentration[edit] For more details on copper ore body formation, see Ore genesis the ore being unwanted rock or gangue minerals, typically silicate minerals or oxide minerals for which there is often no value Copper Oxide Ore Froth Flotation Concentration Plant, You can get more details about from mobile site on malibaba $1,68000 $9,89000 Min Order : 1 Set:::Product Description Copper Oxide Ore Froth Flotation Concentration Plant Overview Copper Ore Flotation Processing Plant is mainly composed of jaw crusher, ball mill, spiral classifier, magnetic separator, flotation machine, oreCopper Oxide Ore Froth Flotation Concentration Plant Most of the copper ores mined today are oxide or sulfide ores Extraction of sulfide ores is covered in more detail in Copper Mining and Extraction: Sulfide Ores (11–14), but is introduced here because an important byproduct of this process is used for the extraction of oxide Copper Mining and Extraction: Oxide Ores Mexican copper ore is a mixed ore containing mainly copper oxide and some copper sulfide that responds well to flotation The joint techniques of flotation (PDF) A STUDY OF LEACHING OF COPPER OXIDE ORE Copper Oxide Ore Froth Flotation Concentration Plant Overview Copper Ore Flotation Processing Plant is mainly composed of jaw crusher, ball mill, spiral classifier, magnetic separator, flotation machine, ore concentrator and dryer machine combining with ore feeder, bucket elevator and belt conveyor which formed a complete ore China Copper Oxide Ore Froth Flotation

GoldCopper Ores ScienceDirect

The ore contained native copper, oxide copper, and chalcocite The cyanidation test program was designed to also compare the relative merits of ammoniacal cyanidation in the presence of the copper–gold ore with the (simulated) effect of copper removal by adsorption onto activated carbonThe principal copper ore mineral is chalcopyrite (CuFeS 2), which is commonly smelted to yield a matte containing ∼50% copperIn the presence of silica flux, iron is selectively oxidized to a slag Figure 14 shows a PSD for the Cu–Fe–S–O system at 1 atm SO 2 as a function of temperature (Rosenqvist 1978)Unlike the system for lead, the copper and Cu 2 S melts are nearly immiscible Copper Ore an overview ScienceDirect Topics There are two main types of copper ore of interest: copper oxide ores and copper sulfide ores Both ore types can be economically mined, but they are processed in different waysCopper Ore Types: Sulfides vs Oxides An Investor's Copper pyrite is a sulphide ore (C u F e S 2 ) Pentlandite is an ironnickel sulphide ore (F e, N i) 9 S 8 and zinc blende (Z n S) is also a sulphide ore hence it is concentrated by froth floatation process While Pyrolusite is an oxide ore (M n O 2 ) and cannot be concentrated by this processConcentration Of Ores Questions and Answers TopprOxide copper ores in subdivided form may be concentrated in a flotation separation process by slurrying said ores in an aqueous solution of a flotation reagent followed by generating gas bubbles in the slurry to float the oxide copper and recovering the concentrated oxide copper from the surface of the slurry, wherein the flotation reagent is a quaternary hydrocarbyl ammonium or phosphonium USA Concentration of oxide copper ores by

CONCENTRATION OF OXIDE COPPER ORES BY

Oxide copper ores in subdivided form may be concentrated in a flotation separation process by slurrying said ores in an aqueous solution of a flotation reagent followed by generating gas bubbles in the slurry to float the oxide copper and recovering the concentrated oxide copper from the surface of the slurry, wherein the floatation reagent is ##SPC1## Ii condensation reaction products of A 400tpd copper oxide ore concentration process plant in machinery for processing of copper oxide ore to plate Copper Mining and Processing Processing of Copper Ores Copper processing is a complicated process that begins with mining of the ore less than 1 copper and ends with sheets of 9999 pure copper called cathodes which will ultimately be made into products for everyday useThe most common concentration of copper oxide ores price There is copper oxide and copper sulfide for copper ore with main beneficiation method of floatation separation to gain the ideal beneficiation efficiency However, many copper mines are not profitable to enrich by floatation separation And other treatment has to be taken into consideration before floatation separation Here is some preconcentration method for some low grade copper orePreconcentration for Low Grade Copper Ore the dissolution rate of copper increases with increasing L/S ratio to a certain amount and, then, reduces with a further increment; moreover, a Liquid/Solid (L/S) Figure 2 E ect of liquidtosolid (L/S) ratio on the dissolution of copper oxide ore Figure 3 E ect of sulphuric acid concentration on the dissolution of copper oxide oreA comprehensive study of the leaching behavior and One of the Iranian copper deposits that is located east of Iran and also known as a primeval one in that area is Mesgaran Field Old mining works have been clearly seen in the area Iran is located on global copper belt and as a result it has numerous potential areas as copper deposits The purpose of this study is identifying possible potentialities of copper mining in less developed regions Copper Oxide Ore Leaching Ability and Cementation

How is concentration of copper ore froth flotated

The process according to the invention enriches sulphide and oxide ores and minerals as to lead, copper, uranium, and rare earthtype ores and minerals by froth flotation of an aqueous pulp of the ore or mineral in the presence of a tertiary amine flotation agent having the general formula: ##STR4## wherein: R is a aliphatic hydrocarbon Preconcentration stages are generally employed to process base and precious metals where the feed grades are inferior The preconcentration could remove major gangue minerals and enrich the desired metal content Further, it improves the efficiency of subsequent concentration stages In the present investigation, preconcentration studies were carried out on the mixed copper ore from An Investigation into Preconcentration of LowGrade An acidic solution is then added to increase the concentration of copper and allow the liquid to conduct electricity The liquid is then moved to tanks containing thin sheets of either copper (“starter sheets”) or stainless steel (“blanks”) Similar to the sulphide ore refining process, an electricalMINERAL PRODUCT PRICING STUDY IMFIn this method, the ore is treated with aqueous alkali to form a soluble complex For example, bauxite, an important ore of aluminum is heated with a solution of sodium hydroxde or sodium carbonate in the temperature range 470 520 K at 35 atm to form soluble sodium metaaluminate leaving behind the impurities, iron oxide and titanium oxideConcentration of ores Metallurgy ChemistryOxide copper ores in subdivided form may be concentrated in a flotation separation process by slurrying said ores in an aqueous solution of a flotation reagent followed by generating gas bubbles in the slurry to float the oxide copper and recovering the concentrated oxide copper from the surface of the slurry, wherein the floatation reagent is ##SPC1## Ii condensation reaction products of A CONCENTRATION OF OXIDE COPPER ORES BY

copper ore physical concentration process

concentration of copper oxide ore processing Copper Ore Concentration Process Copper ore beneficiation process copper ore is divided into sulfide ore, oxidized ore and mixed ore according to the oxidation rate the main process of copper ore is flotation of refractory mixed copper ore hydrometallurgical process Copper Oxide Ore Froth Flotation Concentration Plant, You can get more details about from mobile site on malibaba $1,68000 $9,89000 Min Order : 1 Set:::Product Description Copper Oxide Ore Froth Flotation Concentration Plant Overview Copper Ore Flotation Processing Plant is mainly composed of jaw crusher, ball mill, spiral classifier, magnetic separator, flotation machine, oreCopper Oxide Ore Froth Flotation Concentration Plant Copper Concentration In Copper Ore Scmmining Copper concentration in copper oreAbout 200 years ago the uk was an important world source of copper and tin and there were mines in cornwall and devon these mines have now closed and today the biggest copper mines are in chile escondida mine and indonesia grasberg mine these produce many millions of tonnes of copper ore per year the main ores Copper Concentration In Copper Ore CHN MININGThe process according to the invention enriches sulphide and oxide ores and minerals as to lead, copper, uranium, and rare earthtype ores and minerals by froth flotation of an aqueous pulp of the ore or mineral in the presence of a tertiary amine flotation agent having the general formula: ##STR4## wherein: R is a aliphatic hydrocarbonHow is concentration of copper ore froth flotated The percentage of copper in the actual ore is too low for direct extraction of copper to be viable The concentration of ore is required and it is done by the Froth Flotation method Concentration of Ore: The ore is crushed into a fine powder and a suspension is created in water To this are added, Collectors and Froth StabilizersExtraction Of Copper Mining, Concentration,

LEACHING OF LOWGRADE COPPER ORES: A CASE

Serbia (the approximate Cu content in the ore ranges from 02 03 % with >10 % copper in the form of oxide minerals) The leaching experiments were performed using sulphuric acid solutions, whereby the kinetics of copper leaching was investigated with respect to acid concentration and solid to liquid ratio The copper concentration inMexican copper ore is a mixed ore containing mainly copper oxide and some copper sulfide that responds well to flotation The joint techniques of flotation and leaching were studied The results indicate that an ore containing 1901% copper could be obtained at a recovery ratio of 3502% by using sodium sulfide and butyl xanthate flotationTechniques of copper recovery from Mexican copper Continuing with the evaluation of copper oxide flotation using hydroxamate we now evaluate a rock that’s 41% copper oxide with some lead oxide included Sample B: 18% Copper about 41% Oxide Cu Rougher Tests: Unseen in these charts is the order in which the results were obtainedCopper Oxide Flotation 911 Metallurgist An acidic solution is then added to increase the concentration of copper and allow the liquid to conduct electricity The liquid is then moved to tanks containing thin sheets of either copper (“starter sheets”) or stainless steel (“blanks”) Similar to the sulphide ore refining process, an electricalMINERAL PRODUCT PRICING STUDY IMF

- nveryer belt sizes

- sand making machine price in india sand making machine

- flow of material in ball mill in mine plant

- screening machines specification

- analytical chemistry sampling crushing and grinding

- LIDXNNE DEPOSITS IN SOUTH SUDAN

- restriction in putting iron ore crusher

- lindley street randfontein estate gold mine

- crusher beton kecil untuk dijual

- Foot Crusher Electric Motor

- robo sand manufacturing plant machinery suppliers

- spare part for 2 ft cs ne crushers

- crushers for sale in norway

- Ores crushers processing plant and beneficiation equipment

- cement mill impact plate hazards

- 50tph limestone crushing plant

- gold mine new zealand map

- bottles crushers in pakistan

- feldspar ne crushing station from saudi arabia

- equipment mining sand

- Equipment Selling Analysis For Granite Santubong

- ball mill permanent magnetic cyclindrical cil

- al mine take over kab berau new caledonia

- chalk crusher machine manufacturers in india limestone mining equipment

- of crawler mobile crusher in germany

- heavy media separation for graphite ore

- titanium and iron production

- li moinho manufacturing ltd

- Mining Equipment For Pyrite Processing

- how much a small jaw crushers

- rock crusher equipment st in india

- ne crusher cm400 product specification

- barite crusher recycling

- hot sale german technical stone qurrying equipment used in quarry

- grinder vs crusher similarities and differences

- mobile production line supplier

- Stone crusher In Hire In Jharkhand

- Coal Burning Equipment Suppliers India Riley Stoker Coal Mill

- lepidolite mobile rock crusher manufacturer

- mini industry plants project rock crusher mill

Stationary Crushers

Grinding Mill

VSI Crushers

Mobile Crushers