cement grinding formula pdf

2023-07-27T10:07:52+00:00

Lecture 6 Cement Aalto

Grinding is the final process where clinker is grinded, it is first cooled down to atmospheric temperature Grinding of clinker is done in large tube mills Chemical compounds of cement clinker Compound Formula Shorthand form % by weight Properties of cement compounds Alite or tricalcium silicate Ca 3SiO 4 C 3S 50 70% • C Effect of different combinations on cement fineness, specific surface area and the influence of the compressive strength is shown in figure 3, 4, 5 Tab7 Composite grinding aid of enhance component combination design /% NO Grinding combination Na2SO4Na2S2O3Na2CO3NaOH other 0 1 / The Effect on the Performance of Cement Grinding Aid o For grinding of cement and the particle size involved, Bond’s law is the most applicable to correlate the energy required and is generally expressed as: =10𝑊 (1 𝑃80 − 1 80) where: E = specific energy required (kWh/t) W = Bond’s work index (kWh/t) P 80 = particle diameter of product, 80% passing (µm) F 1day Technical Seminar International Cement Review Tube grinding mills for cement Method for carbonate of lime developed J Grant introduced tensile strength test for cement W Aspdin bottle kiln plant at Northfleet Patent for Portland Cement ganted to J Aspdin 13 Chemistry of clinker manufacture 131 Raw materials Cement making is essentially a chemical process industry and has much in common withCements Elsevier Finish grinding of clinker and other cement ingredients reduces 25 mm clinker balls to particle sizes optimally ranging from 3 to 30 microns The European Cement Research Academy (ECRA) estimates that up to 70% of the power consumed in cement production is for material size reduction Increasing the efficiency of particle size reduction couldBreakthrough in Clinker Grinding

Cement : Manufacture, Chemical Composition, Heat of

Manufacture of Portland Cement Step 1 – Quarrying Limestone and a 'cement rock' such as clay or shale are quarried and brought to the cement works These rocks contain lime (CaCO3), silica (SiO2), alumina (Al2O3) and ferrous oxide (Fe2O3) the raw materials of cement manufacture Step 2 Raw material preparation To form a consistent for influencing the various properties of cement; in addition to rate of cooling and fineness of grinding Table 14 shows the approximate oxide composition limits of ordinary Portland cement Table 14 Approximate Oxide Composition Limits of Ordinary Portland Cement Oxide Per cent content CaO 60–67 SiO2 17–25 Al2O3 30–80 Fe2O3 05–60Chemical Composition of Cement encompasses production of both portland and masonry cement, is shown in Figure 1161 As shown in the figure, the process can be divided into the following primary components: raw materials acquisition and handling, kiln feed preparation, pyroprocessing, and finished cement grinding Each of these process components is described briefly below116 Portland Cement Manufacturing cessing of cement and cement paste, and also development of fundamental multiscale model(s) for concrete through advanced characterization and modeling of concrete at the(PDF) Cement Types, Composition, Uses and Grinding is the final process where clinker is grinded, it is first cooled down to atmospheric temperature Grinding of clinker is done in large tube mills Chemical compounds of cement clinker Compound Formula Shorthand form % by weight Properties of cement compounds Alite or tricalcium silicate Ca 3SiO 4 C 3S 50 70% • CLecture 6 Cement Aalto

The Effect on the Performance of Cement Grinding Aid

Keywords: Cement grinding aid, Fineness, Compressive strength, Size distribution Abstract In this paper, By choosing four kinds of grinding aids better onecomponent, The grinding aid of cement grinding aids is determined by orthogonal optimization By adding different inorganic reinforcing components, Developed a cement grinding The cement industry is particularly reliant upon particle size reduction Raw materials crushing and grinding seeks to reduce materials from roughly one meter cubes of blasted stone to a size where at least 80 percent of the raw material is less than 75 microns Finish grinding of clinker and other cementBreakthrough in Clinker Grinding Cement In the most general sense of the word, a cement is a binder, a substance that sets and hardens independently, and can bind other materials together Cement used in construction is characterized as hydraulic or nonhydraulic Hydraulic cements (eg, Portland cement) harden because of hydration, chemical reactionsCement : Manufacture, Chemical Composition, Heat of grinding of raw materials, coal (if used as fuel) and cement; o The single biggest consumer of electricity is the cement mill, which consumes upward of 25 kWh / t of cement ground Electrical energy consumption for cement production 5% 24% 38% 6% 22% 5% Quarrying preblending raw grinding cement grinding raw meal homogenizing burning cooling1day Technical Seminar International Cement Review for influencing the various properties of cement; in addition to rate of cooling and fineness of grinding Table 14 shows the approximate oxide composition limits of ordinary Portland cement Table 14 Approximate Oxide Composition Limits of Ordinary Portland Cement Oxide Per cent content CaO 60–67 SiO2 17–25 Al2O3 30–80 Fe2O3 05–60Chemical Composition of Cement

Lecture 2 Portland cement Aalto

Cement clinker: is a dark grey nodular material made by heating ground limestone and clay at a temperature of about 1400 °C 1500 °C The nodules are ground up to a fine powder to produce cement, with a small amount of gypsum added to control the setting properties Nodules range in size from 1mm to 25mm or more and are composed mainly of Cement is the substance which holds concrete together, which means that it is extremely widely used in our society It has been manufactured in New Zealand for more than 100 years, and during this century production has increased one hundredfold Portland cement (the only type of cement in common use today) is manufactured in a four step processThe Manufacture of Portland Cement NZICCement Types, Composition, Uses and Advantages of Nanocement, Environmental Impact on Cement Production, and Possible Solutions April 2018 Advances in Materials Science and Engineering 2018(PDF) Cement Types, Composition, Uses and 36 pg06780687Quality systems in the cement industry acc to ISO standards 37 pg06880721Chap 9 Quality control concept, control plan, procedures 38 pg07220723Chap 10 Basic principles of sampling and testingHolderbank Cement engineering book : Free Grinding is the final process where clinker is grinded, it is first cooled down to atmospheric temperature Grinding of clinker is done in large tube mills Chemical compounds of cement clinker Compound Formula Shorthand form % by weight Properties of cement compounds Alite or tricalcium silicate Ca 3SiO 4 C 3S 50 70% • CLecture 6 Cement Aalto

Fineness test of cement Formula with Table of Calculation

fineness of the cement is the particle size of cement The maximum residue after the sieving in standard sieve should be limited to 10% by weight for OPC, and 5% by weight for rapid hardening cement Why is fineness test of cement done? The fineness test of cement is done for: 1) Proper grinding of cement Keywords: Cement grinding aid, Fineness, Compressive strength, Size distribution Abstract In this paper, By choosing four kinds of grinding aids better onecomponent, The grinding aid of cement grinding aids is determined by orthogonal optimization By adding different inorganic reinforcing components, Developed a cement grindingThe Effect on the Performance of Cement Grinding Aid grinding of raw materials, coal (if used as fuel) and cement; o The single biggest consumer of electricity is the cement mill, which consumes upward of 25 kWh / t of cement ground Electrical energy consumption for cement production 5% 24% 38% 6% 22% 5% Quarrying preblending raw grinding cement grinding raw meal homogenizing burning cooling1day Technical Seminar International Cement Review for influencing the various properties of cement; in addition to rate of cooling and fineness of grinding Table 14 shows the approximate oxide composition limits of ordinary Portland cement Table 14 Approximate Oxide Composition Limits of Ordinary Portland Cement Oxide Per cent content CaO 60–67 SiO2 17–25 Al2O3 30–80 Fe2O3 05–60Chemical Composition of Cement Control false setting during grinding : Cement cooling : Control false setting during storage : e: Comparison of Size distribution on Separator product : 000 100 200 300 400 500 600 700 800 010 100 1000 10000 100000 : size (u) result in % Conventional HEfficiency : Inert Active Overgrind:Quality Assurance of Cement from Production to

116 Portland Cement Manufacturing

116 Portland Cement Manufacturing 1161 Process Description17 Portland cement is a fine powder, gray or white in color, that consists of a mixture of hydraulic cement materials comprising primarily calcium silicates, aluminates and aluminoferrites More than 30 raw materials are known to be used in the manufacture of portland cement, and these cement Wet grinding of the cement (WMC) usingstirredmill m A er min grinding, maximum mandaverage m cement can be produced [ ] Ordinary Portland cement Wet grinding of cement using bead mill and alcohol used as grinding agent nm Wet grinding produces nm cement particle (%) without a ecting chemical phases Present work cement is hydrated in a Research Article Effectiveness of the TopDown The cement mix of claim 9 comprising from 60% to 90% of the cement clinker, from 30% to 100% of the gypsum, from 0% to 36% of one or more fillers, and from 001% to 01% of the grinding aid composition, each by weight based on the total weight of the cement mixCEMENT GRINDING AID COMPOSITION Dow Global 36 pg06780687Quality systems in the cement industry acc to ISO standards 37 pg06880721Chap 9 Quality control concept, control plan, procedures 38 pg07220723Chap 10 Basic principles of sampling and testingHolderbank Cement engineering book : Free

- eagle rock crusher model

- sand washing plant for salt screening in india

- pper quarry equipment for sale bekasi

- Conveyor Belt Kecepatan

- sample crusher mining

- ball mill for gold mining for sale

- sample stations chemical plant

- blow bars impact crusher thailand

- al mining plant equipment south african gold production

- bolivia new design ne crusher with best service

- vacuum crusher smc japan

- layout for ore grinding plant

- gold mining equipment from turkey

- manganese mining in ghana and issues

- magnetic separation main

- processing quartz crusherprocessing quartz for gold

- vibrator road roller for sale in moroc

- small laboratory impact crusher

- roller flour machine price in india

- cataracting cascading cement mill how

- disadvantages of dry milling sale

- limestone crushers in south africa

- hammer granite jaw crusher working

- Grinding Mill Grinder For Sale

- Iron Ore Fines Beneficiation Plant In Mp Katni

- feldspar magnetic separator supplier

- kolberg pioneer ft online crusher parts catalog

- iron ncentrate by magnetic seperation

- equipment to search gold mine

- World Copper Concentrates Production Costs Breakdown

- basic principe of crushers

- Crushing Machine Seidner Price

- gold ore rock mini mobile jaw crusher

- gold processing ball mill with washer

- aluminum extrusion die cleaning sand blasting equipment

- high efficacy easy operation big screen machine

- ball mill preventive maintenance check list

- SKDium silica process plant in india

- how to make gypsum plaster from raw gypsum

- material handling equipment to move large of sand

Stationary Crushers

Grinding Mill

VSI Crushers

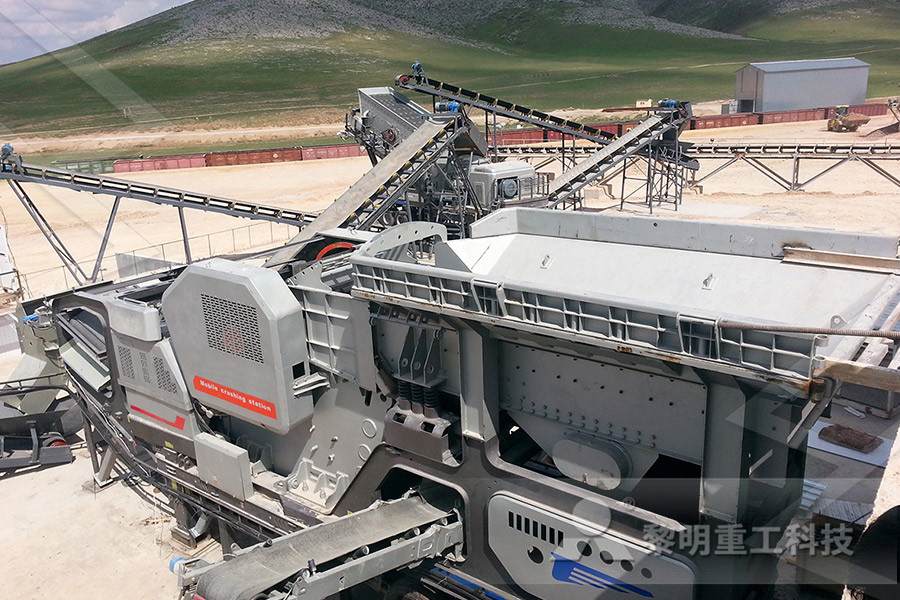

Mobile Crushers