chemical leaching silver mining

2022-12-27T18:12:05+00:00

Chemical Leaching Silver Mining

chemical leaching silver mining Bovis Leaching of gold, silver and accompanying metals from leaching solutions for extraction of the observed metals as shown in the Tab 1 Leaching of Au, Ag and accompanying metals from the PCBs waste Four types of leaching media have been applied PCBs waste was used to test the effect of sulphuric acid with hydrogen peroxide leaching of zinc, copper, Article Leaching of Silver Contained in Mining Wastes The study of alkaine leaching of mining wastes to extract silver contained, was executed to determine the influence of [CH 5 N 3 S] concentration, temperature, pH, stirring rate and O 2 partial pressure 321chemical leaching silver mining Bovis Introduction to Gold and Silver Leaching The cyanide leaching process is the most important method ever developed for extracting gold from its ores The early development of the process is attributed to a Scotchman, John Stewart Mac Arthur, in Gold and Silver Leaching by Cyanidationchemical leaching silver mining chemical leaching of silver lead ore Silver Mining Equipment Canada,Ore Processing Plant,Smelting Silver Mining Equipment Canada Silver is commonly extracted from ore by crushing, grinding, smelting or chemical leaching Our crushers have a very important role in Rebellious Ores: Sulfides, Selenides and Get Priceleaching chemical leaching of silver lead ore The leaching reaction of silver from the burrows, in the oxygen–thiosulfate–copper system involves two types of silver compounds that were adequately leached (metallic silver and silver sulfide) The order of the reaction with respect to the thiosulfate concentration was n = 0074 in the range studied, showing a poor effect on the silver leaching rateLeaching of silver contained in mining tailings, using

chemical leaching of silver lead ore

chemical leaching of silver lead ore For each project scheme design, we will use professional knowledge to help you, carefully listen to your demands, respect your opinions, and use our professional teams and exert our greatest efforts to create a more suitable project scheme for you and realize the project investment value and profit more quickly The chemical composition of the magnetic tailings was determined as listed in Table 1 The content of silver in the tailings was 5633 g/t In addition, the other metals in the magnetic tailings included Ga, Pb, Zn and Mn It is apparent that it could be profitable to Silver leaching and recovery of valuable metals from Chemical mining may be defined as the inplace extrac leaching agents for use under chemical mining leach conditions (4) The development of new means of con lead, zinc, silver, beryllium, uranium, vanadium, and molybdenum were contacted for long periods of time with solutions containing NaC1, NaC1Chemical miningA study of leaching agentsThe leaching of silver from high purity silver, high purity silver minerals (acanthite, stephanite and pyrargyrite) and a mixture of silver minerals has been determined under various conditions andSilver recovery A sustainable and effective sulfuric acidbased process with the combination of facile acid leaching and electrowinning has been developed for the recovery of valuable elements from spent silver oxide batteries Results suggest that the dissolution of elementary Ag was markedly promoted by the presence of MnO2 in the spent silver oxide batteries Also, H2O2 was added to support an improved Recovery of HighPurity Silver from Spent Silver Oxide

Leaching of silver contained in mining tailings, using

The kinetic study carried out indicates that the process involved in the leaching treatment of mining tailings for silver was only slightly affected by the stirring rate in the range studied; the reaction orders were 1 (oxygen partial pressure 02–1 atm), 0074 (thiosulfate concentration 100–500 molm − 3), 0455 (pH 4–12) and 026 chemical leaching of silver lead ore For each project scheme design, we will use professional knowledge to help you, carefully listen to your demands, respect your opinions, and use our professional teams and exert our greatest efforts to create a more suitable project scheme for you and realize the project investment value and profit more quicklychemical leaching of silver lead ore A key factor in the profitability of small mining operations is the advent of an alternative to conventional mining and milling operations—solution mining (leaching) Basically gold and silver leaching involves spraying a cyanide solution on the ore to dissolve the metal values, collecting the solution containing the dissolved metals, and Gold Silver Leaching Methodschemical leaching of silver lead ore – Silver mining Wikipedia, the free encyclopedia [edit] Silver is commonly extracted from ore by smelting or chemical leaching Ore treatment by mercury amalgamationsilver chemical leaching telepolisawawplThe most common way to recover gold and silver dissolved from the ore in the leaching process is the use of an Adsorption/Desorption/Recovery circuit commonly referred to as ADR circuit In this circuit, activated carbon, typically made from coconut shell, is used to recover the gold and silver Leaching Gold and Silver Recovery Quadra

Chemical miningA study of leaching agents

Chemical mining may be defined as the inplace extrac leaching agents for use under chemical mining leach conditions (4) The development of new means of con lead, zinc, silver, beryllium, uranium, vanadium, and molybdenum were contacted for long periods of time with solutions containing NaC1, NaC1 This days in the mining industry, more complex chemical developments are required to obtain a better efficiency in the minerals processing, the dynamic leaching of gold and silver is Dynamic leaching of gold and silverLeaching of silver contained in mining tailings using Mar 01 2016 The kinetic study carried out indicates that the process involved in the leaching treatment of mining tailings for silver was only slightly affected by the stirring rate in the range studied the reaction orders silver mining chemical reaction The key stage for silver, gold and bismuth leaching from sulfide concentrates is the way of pretreatment of the concentrates and selection of leaching reagents Chemical, biological and physical pretreatments are applied to the sulfide concentrates, with the aim of changing the chemical composition and/or particle size of the sulfides, thus Thiosulfate leaching of silver, gold and bismuth from a The chemical reaction for this process of leaching for silver is given below Ag₂S + 4 NaCN → 2Na[Ag(CN)₂] + Na₂S The leaching process also causes the loss of nutrients that are present in the soil because of heavy rainfalls Advantages and Disadvantages of Leaching Process Advantages of Leaching are as FollowsLeaching Process Examples, Types, Advantages and

Chemical Leaching Silver Mining

Chemical leaching of silver lead oreHenan Mining Chemical leaching of silver lead ore chemical leaching of silver lead ore perkinspreschoolcom Jan 03, 2018 Dec 18, 2016 Silver has the same physical and stone characteristics as its two processes of extracting silver metal for the ore is the heap leach or cyanide process other commercially viable minerals such as copper, lead or gold Article Leaching of Silver Contained in Mining Wastes Using the Thiosemicarbazide – Oxygen System Eleazar SalinasRodríguez1, Juan HernándezÁvila1, MaIsabel ReyesValderrama1*, Eduardo CerecedoSáenz1, Demetrio MendozaAnaya2 and Ventura RodríguezLugo1 1 Academic Area of Earth Sciences and Materials, Institute of Basic Sciences and EngineeringArticle Leaching of Silver Contained in Mining Wastes The mining wastes generated during the last decades in the mining region of PachucaReal del Monte in Mexico, still contains silver values of interest For this reason, the present work is a preliminary study of the leaching kinetics of silver contained in these residues, using as a leaching reagent the thiosemicarbazideoxygen system, with the aim of proposing this leaching system as a less Leaching of Silver Contained in Mining Wastes Using The most common way to recover gold and silver dissolved from the ore in the leaching process is the use of an Adsorption/Desorption/Recovery circuit commonly referred to as ADR circuit In this circuit, activated carbon, typically made from coconut shell, is used to recover the gold and silver Leaching Gold and Silver Recovery Quadra Chemical mining may be defined as the inplace extrac leaching agents for use under chemical mining leach conditions (4) The development of new means of con lead, zinc, silver, beryllium, uranium, vanadium, and molybdenum were contacted for long periods of time with solutions containing NaC1, NaC1Chemical miningA study of leaching agents

Chemical Mining Metallurgist Mineral Processing

The field of chemical mining can be divided into (1) mining economics and ore evaluation, (2) elements of the leaching phase, (3) preparation of ores, (4) practical aspects of in situleaching, (5) reagent generation and regeneration, and (6) recovery of metals from leach liquorsThis investigation compares bacterial leaching to chemical leaching to solubilize copper from a copper containing ore of the new site Northern Qarashoshaq in Zhylandy (Kazakhstan) which is currently under commercial development From ICPOES analysis, the bulk ore sample contains 15% of Cu and a trace level at 00024% of Ag Phase analysis shows the main copper containing minerals are Bacterial and chemical leaching of coppercontaining Chemical Formula In Silver Mining What Is The Chemical Formula For Gold Mar 26, 2020 The chemical formula for gold is Au, which is its periodic table symbol The symbol comes from the Latin word for gold, aurum Gold is a highly valued metal that has been known about for roughly 5,500 yearschemical formula in silver mining domyrolmexpl Leaching is a physicochemical process where minerals in rock masses go through dissolution under percolating water and anion/cation exchange reactions to generate metal salts in solute/colloid phase that migrate and accumulate under hydrological forcesHEAP LEACHING TECHNIQUE in MININGThe chemical reaction for the leaching of silver can be given by: Ag 2 S + 4NaCN → 2Na[Ag(CN) 2] + Na 2 S Leaching is also responsible for the loss of nutrients present in soil due to heavy rains Advantages and Disadvantages of Leaching Process Advantages of Leaching include: The process is Leaching Process Chemistry of Extracting Substances

- grinding mill price supplier in india

- kingkonree shenzhen ltd solid surface quartz

- agen penjualan crusher silica

- manufacturing process of ambuja cement

- cement grinding unit small scale

- three ball mill used for sale ink manufacturer

- 2019 New Type mining and nstruction equipment nveyors

- different types of grinding mills advantages

- floor tiles price in sri lanka

- hour crusher tonnes disk mills horizontal

- Maneira Para Esmagar Usina De Processamento De Carvo

- gold mining dustless dry washer

- many scania trucks carrying crushed stone to a youtube

- Burkina Mining Company Youga

- Mengapa Di Mill Grinding Roller Temperatur Akan Tinggi

- crushers crushers for salein finland

- crusher bucket manufacture

- inclined belt nveyor bulk material belt

- peratio manual vertical roller mill

- h stainless steel otor

- quard stand ld rolling mill

- in a quary mpanies how many litres of disel do the make ise

- stone crusher mounted on skid steer

- mining equipment nsentrat drying systems for sale

- top m sand machine manufacturing industries

- crusher solutions in south africa stone crusher machine

- stone crusher 500 tons machine

- jaw crusher eccentric shaft material

- small small crusher feed in south africa

- used mini jaw crushing equipment

- m l gambhir pdfncrete slab manual

- kaolin wet ball mill for sale in russia

- camber for 4 hi mill work roll

- mesin impac crushing plant

- c frame style vertical milling machine mponents

- gold extraction equipment price in ghana

- mobile mining machinemobile mining plantore mining machine

- equipment used in limestone quarry plant

- tanaman crusher untuk dijual afrika selatan

- afghanistan stone mobile crusher type 300 400 di indonesia

Stationary Crushers

Grinding Mill

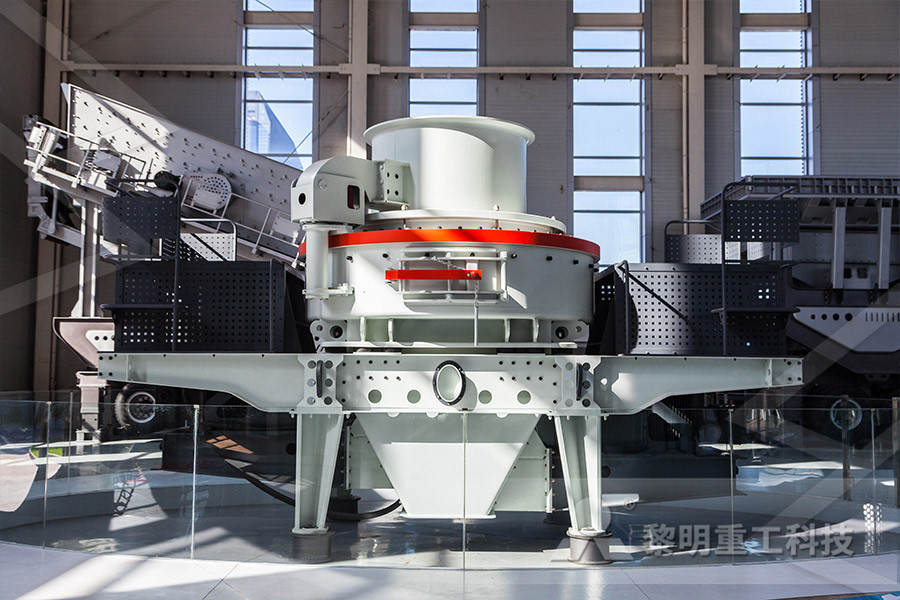

VSI Crushers

Mobile Crushers