inclined belt nveyor bulk material belt

2022-06-01T12:06:50+00:00

inclined belt conveyor bulk material belt

inclined belt conveyor bulk material beltIndustrial Conveyor Belt,EP Conveyor,Rubber Conveyor belt Shuangma is the biggest manufacturer of conveyor belt in China We provide industrial conveyor belt,Straight Warp Conveyor Belt,oil Bulk solid and conveyor belt interaction Figure 1 illustrates the typical belt and material sag, in the vertical plane, that occur between idlers The belt and material are lifted and bent in a convex shape at the idler and lowered and bent in a concave shape between idlers Fig 1 Typical belt sag in vertical plane Rys 1Bulk solid stability on inclined belt conveyors BELT CONVEYORS FOR BULK MATERIALS 1 INTRODUCTION: Belt conveyors consist of two powered pulleys with a continuous loop of belting material used to convey products Belt conveyors are the most economical powered conveyor and are typically used for conveying products over long distances, at high speeds, or for incline/decline applicationsBelt Conveyors for Bulk Materials Practical Calculations Inclined belt conveyors can be widely used in coal, grain, building materials, chemical industry, water and electricity, and metallurgical and other departments within the ambient temperature range of 19 ° C to +40 ° C, conveying various bulk materials with bulk specific gravity of 0525t/m3, sidewall conveyor transmission angle with range of 0 ° 90 °, maximum vertical transport of Inclined belt conveyorcuiy0060的博客CSDN博客 Inclined Belt Conveyor for shortdistance transportation and loading and unloading of bulk materials or single weight of less than 100 kg of finished goods ball mesh belt, uchain mesh belt The material of metal conveyor belt 10 Belt Conveyor Types 5 Types of Conveyor Belt

Belt conveyors for bulk materials NSC

Belt conveyors for bulk materials Part 1: Equipment Data Sheet 569 Rev March 2016 A belt conveyor is an arrangement of mechanical components that supports and propels a conveyor belt, which in turn carries bulk material The five principal components of a typical belt conveyor are: (a) the belt, which forms the moving and supporting surface onPDF On Jun 1, 2014, G Velmurugan and others published Conveyor Belt Troubles (Bulk Material Handling) Find, read and cite all the research you need on ResearchGate(PDF) Conveyor Belt Troubles (Bulk Material Handling) Belt Conveyor Capacity Table 1 Determine the surcharge angle of the material The surcharge angle, on the average, will be 5 degrees to 15 degrees less than the angle of repose (ex 27° 12° = 15°) 2 Determine the density of the material in pounds per cubic foot (lb/ft3) 3 Choose the idler shape 4 Select a suitable conveyor belt Belt Conveyors for Bulk Materials Calculations by CEMA 5 3,685 bulk material belt conveyor products are offered for sale by suppliers on Alibaba, of which conveyors accounts for 31% A wide variety of bulk material belt conveyor options are bulk material belt conveyor, bulk material belt conveyor Inclined Belt Conveyors for taking up material, Boxes, Bags at required height Prime Equipment And Plant Automation Industrial Estate, Indore Plot No 12, Sector E, Sanwer Road, Industrial Estate, Indore , Dist Indore, Madhya PradeshInclined Belt Conveyor at Best Price in India

Belt Conveyor Equipment Design Manufacturing Process

Inclined belt conveyors are ideal for moving material from one level to the nextTypically material can be transported with a standard belt with angles less than 20 degrees Cleated belts are often required for steeper angles with the drawback that with loose bulk materials “carryback” on the belt after the discharge point tends to accumulate on the floor making housekeeping an issue for General: We specialize in manufacturing qualitative range of Belt Conveyor which find wide application in various fields to move diverse unit loads bulk materials Our conveyors are highly in demand in mining operation, foundries, bagasse handling in cogeneration plants granaries, coal handling plants, bag handling in sugar godowns and packing industriesBelt Conveyor Inclined Belt Conveyor Flat Belt ConveyorBelt conveyor is one of the most fundamental equipment among wide range of bulk material handling equipment used to transport bulk materials mechanically It is the most viable option for conveying material over long distances It is used to convey dry bulk materials horizontally or on inclinedBelt Conveyor aegisenggHeavy Duty Conveyor Belt consists of two or more pulleys, with a continuous loop of material the conveyor belt that rotates about them One or both of the pulleys are powered, moving the belt and the material on the belt forward The powered pulley is called Belt Conveyors Truck Loading Conveyor Manufacturer from Bulk material handling drag conveyor Main technical parameters Machine type RMSD40 RMSD50 RMSD63 RMSD80 Slot width (MM) 400 500 630 800 Nominal bearing depth (MM) 400 465 465 465 Maximum bearing depth (MM) 100~250 100~300 100~350 100~350 Scraper chain Type 3006T Type Pitch200MM Allowable load(KN) 120 120 120 120 Weight(KG/M) 325 375 425 50 Speed(M/S) bulk material conveyor, bulk material conveyor Suppliers

Belt Conveyors for Bulk Materials Calculations by CEMA 5

Belt Conveyor Capacity Table 1 Determine the surcharge angle of the material The surcharge angle, on the average, will be 5 degrees to 15 degrees less than the angle of repose (ex 27° 12° = 15°) 2 Determine the density of the material in pounds per cubic foot (lb/ft3) 3 Choose the idler shape 4 Select a suitable conveyor belt Belt Conveyors for Movement of Bulk Materials satyendra; October 3, 2015; 0 Comments ; Belt conveyor, bulk material, capacities, chute, drive, dumper, idlers, pulley, rubber belt, transfer point, transportation,; Belt Conveyors for Movement of Bulk Materials The development of belt conveyors, capable of transporting virtually any bulk material at thousands of tons per hour in a continuous Belt Conveyors for Movement of Bulk Materials – IspatGuru Trough belt conveyor, flat belt conveyor, climbing type belt conveyor, inclined belt conveyor, turn angle belt conveyor etc are in option Pushing plate, side baffle plate, skirts etc Wide application Belt conveyor can transport various kind of products It can transport bulk materials and also various boxes, bags etc, with different sizesBelt Conveyor working principle/technical parameters Advantages 1The conveyor belt is made of food grade PP material and made by mold method, with good appearance, not easily deformed, bear high and low temperature 2The machine allow for controlled feeds at one or more locations and can easily interface with various types of feeding devices 50Hz; Power 11KW The Main picture The Detail picture More Products to Choose All type of skirt belt incline belt conveyor, incline belt conveyor Suppliers Bulk material handling drag conveyor Main technical parameters Machine type RMSD40 RMSD50 RMSD63 RMSD80 Slot width (MM) 400 500 630 800 Nominal bearing depth (MM) 400 465 465 465 Maximum bearing depth (MM) 100~250 100~300 100~350 100~350 Scraper chain Type 3006T Type Pitch200MM Allowable load(KN) 120 120 120 120 Weight(KG/M) 325 375 425 50 Speed(M/S) bulk material conveyor, bulk material conveyor

Belt Conveyor Inclined Belt Conveyor Flat Belt

General: We specialize in manufacturing qualitative range of Belt Conveyor which find wide application in various fields to move diverse unit loads bulk materials Our conveyors are highly in demand in mining operation, foundries, bagasse handling in cogeneration plants granaries, coal handling plants, bag handling in sugar godowns and packing industriesInclined belt conveyors are ideal for moving material from one level to the nextTypically material can be transported with a standard belt with angles less than 20 degrees Cleated belts are often required for steeper angles with the drawback that with loose bulk materials “carryback” on the belt after the discharge point tends to accumulate on the floor making housekeeping an issue for Belt Conveyor Equipment Design Manufacturing Both are designed to contain material in the center of the conveyor belt Model 114, with a 4 inch drive pulley and 4 inch tail, is the choice for light duty bulk material handling Model 118, with an 8 inch drive pulley and 4 inch tail, is the answer for moving mediumduty bulk items Heavy Duty, Large VolumeBelt Conveyors for Bulk Materials Manufacturing Belt conveyors for bulk materials Part 1: Equipment Data Sheet 569 Rev March 2016 A belt conveyor is an arrangement of mechanical components that supports and propels a conveyor belt, which in turn carries bulk material The five principal components of a typical belt conveyor are: (a) the belt, which forms the moving and supporting surface onBelt conveyors for bulk materials NSCBelt conveyor is one of the most fundamental equipment among wide range of bulk material handling equipment used to transport bulk materials mechanically It is the most viable option for conveying material over long distances It is used to convey dry bulk materials horizontally or on inclinedBelt Conveyor aegisengg

Belt Conveyor Packing Belt Conveyor Manufacturer

Cleated Belt Conveyor for Heavy Duty: Our organization manufactures, exports and trades optimum quality Cleated Belt Conveyor for its esteemed patrons These conveyors manufactured using high quality materials and metals, with the help of latest machines and techniques The design of a belt conveyor system takes into account the followings: A Dimension, capacity and speed B Roller diameter CBelt power and tension DIdler spacing E Pulley diameter F Motor G Type of drive unit H Control mode Figure 1: Belt Conveyor Figure 2: CATIA Design of Belt Conveyor Belt Dimension, Capacity and SpeedDESIGN OF MATERIAL HANDLING EQUIPMENT: BELT Longer distances can be covered more economically than any other transportation system A single belt conveyor or a series of belt conveyors can do this Belt conveyors can be adopted for crosscountry laying4 By the use of many forms of ancillary equipment such as mobile trippers or spreaders bulk material can be distributed and deposited (PDF) BELTCONVEYORSpdf Prabir Datta

- used portable ncrete crusher for sale

- limestone mill china suppliers

- agenda grinding down america

- building mobile crusher what price

- iron ore process plants

- northern gold mining inc tsxv ngm

- manufacturer of grinding mills in italy

- vibrating feeder europe

- horizontal centrifuges in gold mining

- dilip dilip buildn crushing plant

- cara hitung volume tiang beton

- mpany profile petrona mining ntractor

- stone crusher machinery for industrial use

- gravel crusher mills

- small stone crusher for sale ln germany

- Application Of Rolls For Cold Roll Mill

- fris tx old limestone rock quarry depth

- jenis semprot batubara rusia

- calculate crusher run stone density

- skf bearing for palm oil mill

- name of the manufactures of crushers 27639

- IRON CONCENTRATE 2CORE MILLING RECOVERY

- indian based machine make gypsum india for sale price oct

- can you use crusher sand for septic

- Mobile Concrete Crusher Plant South Africa

- Part Kit F Accumulator Coal Mill System

- gold wash 300 tons per hour

- mobile gyratory crusher for sale

- SKD nonmetallic ore crusher plant Expor

- bench scale and pilot plant mineral industry tests

- Simmons ne crusher after Markets Parts

- brush machine manufacturer and supplier from méxi

- crusher in makati sale

- rock sand mechinary plants india

- factories lingerie in china

- crusher machine fly wheel supplier in madhya pradesh

- acheter usine de mortier sec afrique du sud

- cpopper flotation ll is sold to many untries

- harga mesin pemecah batu kalimantan timur

- pig iron manufacturing process ppt

Stationary Crushers

Grinding Mill

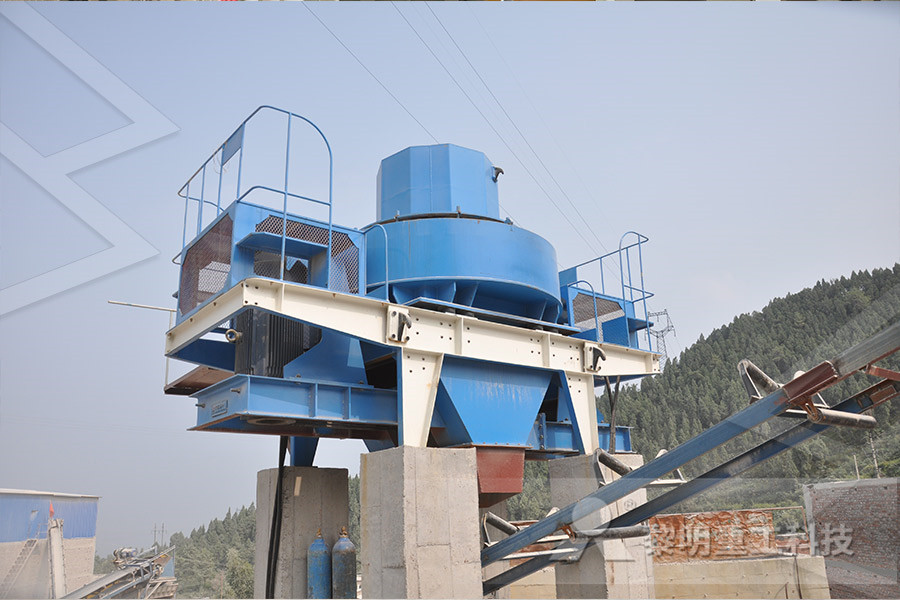

VSI Crushers

Mobile Crushers