nickel extrating from nickle ore

2020-05-02T16:05:16+00:00

Extraction of Nickel Nickel Ore Mining Mining

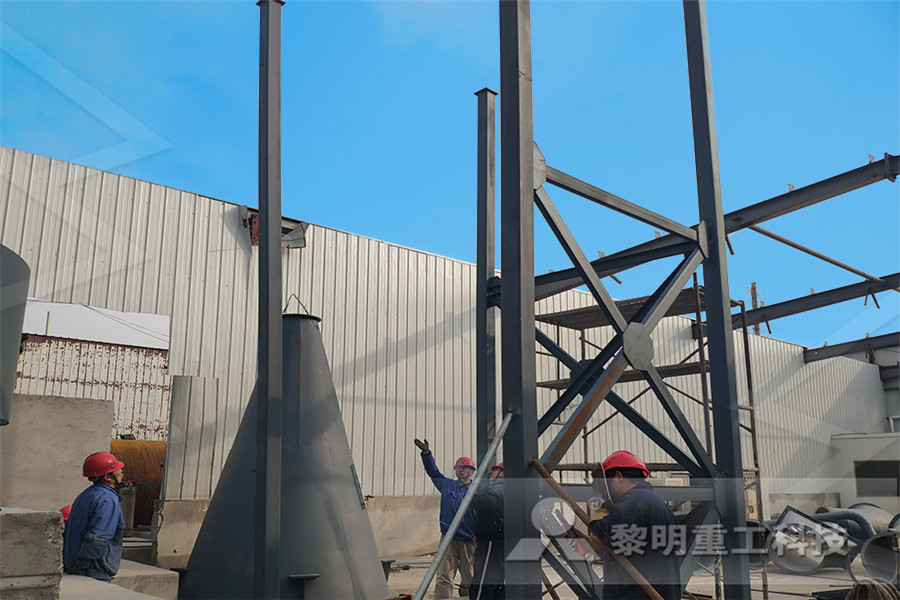

Extraction of Nickel This paper introduces the extraction of nickel process and characteristics of laterite nickel ore dressing, highlights the nickel ore crushing, washing in the nickel production process design 1 Description of nickel ore The laterite nickel ore is complex in composition and can be roughly divided into two types: limonite type and silicon magnesiumnickel type Nickel processing Nickel processing Extraction and refining: The extraction of nickel from ore follows much the same route as copper, and indeed, in a number of cases, similar processes and equipment are used The major differences in equipment Nickel processing Extraction and refining Britannica This content was downloaded from IP address 181214208220 on 31/01/2018 at 00:39(PDF) Nickel extraction from nickel matte Nickel sulfide ores occur as disseminated or massive ore bodies All the nickel in nickel sulfide ores occurs in the mineral pentlandite hosted by silicate rock minerals referred to as gangue rockExtraction of Nickel and Cobalt from Sulfide Ores HYDROMETALLURGICAL APPROACHES: (Cu₈Ni₁₆Fe₁₀)→Limonite (FeO(OH)nH₂O) • Solvent Extraction – Electrowinning approach to lateritic ore beneficiation, is a hydrometallurgical method that relies on leaching, extractants, and electrowinning to produce nickel from ore Nickel and its extraction SlideShare

Nickel mining in Australia – history, top locations and

Nickel ore grades in the 1960s had 4% nickel but within a decade the nickel ore grade in Australia fell to 2% Over the last 20 years, low grade laterite or sulphide deposits have posted an average ore grade of about 12% Magmatic nickelcopper sulfide deposits formed due to mafic or ultramafic rocks Formation began in the earth’s magma Alex Newth Date: February 13, 2021 Nickel ore must melt until it becomes a product known as liquid matte, which is usually around 45 percent nickel Nickel smelting is the process that nickel ore goes through to eventually remove impurities and leave What Is Nickel Smelting? (with picture) InfoBloom At present, sulfide nickel deposits are the primary source of mined nickel Sulfide ore grades range from 0158% Ni, with 93% of known deposits ranging from 022% Ni All nickel ores have relatively low nickel content, the classification is as follows: highgrade nickel ore has Ni content greater than 18%, middlegrade nickel ore Enhanced methods for nickel recovery from low Nickel ore is one of ANTAM’s important products ANTAM produces and exports high grade nickel ore with a minimum 18% nickel content and a maximum 25% iron content (saprolite) and low grade nickel ore with a 12% minimum nickel content (limonite) and minimum 25% iron content ANTAM’s nickel ore mines are at Pomalaa, Tanjung Buli and Gag IslandPT ANTAM Tbk Nickel 1 Introduction In general, increasing attention has been paid to laterite ores as an alternative to nickel sulfide ore , , , , Lowgrade laterite ores are an important nickel resource for nickel extraction , , According to the statistical analysis of nickel resources, these laterite ores account for up to 72% of the global nickel resources but are only related to 42% of the world's nickel Separation and recovery of iron and nickel from low

Industrial Ultrafine Grinding Plants In Turkey And

Nickel Extrating From Nickle Ore Aug 24, 2017 The mining and processing of nickelrich ores can generate high loadings of dust in the air, that contains high concentrations of potentially toxic metals, including nickel itself, copper, cobalt Nickel Plating Services in Missouri and Illinois Nickel plating is another popular electroplating service used in the engineering, automobile, and electronics uses of nickel plating vary depending on the type of nickel In general, the metal is valuable for its hardness, lubricity, resistance to wear, and magnetic attributes MORE INFO > Live Chatnickel plating commercial drukilaserpolskaplNew nickel extraction process aids Australian mining industry Oct 21, 2013 3pujadanickelmine Nickel Limited (DNi) and Perth CSIRO have collaborated to produce a method of nickel extraction from low grade ore Chat Onlinenickel ore pujada mining asiacrusher Plants absorb mineral ions through their roots Phytoextraction makes use of this: plants are grown in soil that contains low grade ore the plants absorb metal ions through their roots and Biological methods of metal extraction Higher Unreactive metals such as gold are found in the Earth's crust as uncombined elements However, most metals are found combined with other elements to form compounds An ore Extracting metals How are metals with different

The Extraction of Copper Chemistry LibreTexts

The Process The concentrated ore is heated strongly with silicon dioxide (silica) and air or oxygen in a furnace or series of furnaces The copper(II) ions in the chalcopyrite are reduced to copper(I) sulfide (which is reduced further to copper metal in the final stage)Aluminium doesn’t occur as a isolated ore (it’s too reactive with other compounds) but as one combined with other minerals, chief of which is bauxite Bauxite is mined from open mines from locations mainly in a wide belt around the equator Bauxite is a mixture of aluminium hydroxide, iron Aluminium production environmental impact1aolin clay manufacturing machinery machines involved in kaolin clay manufacturing process as kaolin, in brazil, france, kaolin processing line, kaolin grinidng machine manufacturer, the kaolin processing plant manufactured by machinerymachine manufacturer and seller and can offer you the best pricing for the best equipment if youMachineries For Kaolin Processing Of the five minerals, spodumene is the most commonly used for lithium production After it is mined, spodumene is heated to 2012 degrees Fahrenheit and then cooled to 149 mercial Lithium Production and Mining of LithiumDYNABRADE 52715 Air Grinder,12,000 rpm,73/4 In L Air Grinder, Grinder Orientation Straight, Free Speed 12,000 rpm, Wheel Dia 11/4 In, Wheel Type Type 1, HP 100 HP, Heavy Duty, Average CFM @ 15 Second Run Time 950, CFM @ Full Load 380, Air Inlet 3/8 Inthe p for air powered grinder for cones plugs 12000 rpm

Biological methods of metal extraction Higher

Plants absorb mineral ions through their roots Phytoextraction makes use of this: plants are grown in soil that contains low grade ore the plants absorb metal ions through their roots and The Process The concentrated ore is heated strongly with silicon dioxide (silica) and air or oxygen in a furnace or series of furnaces The copper(II) ions in the chalcopyrite are reduced to copper(I) sulfide (which is reduced further to copper metal in the final stage)The Extraction of Copper Chemistry LibreTextsNickel Extrating From Nickle Ore Aug 24, 2017 The mining and processing of nickelrich ores can generate high loadings of dust in the air, that contains high concentrations of potentially toxic metals, including nickel itself, copper, cobalt Industrial Ultrafine Grinding Plants In Turkey And Unreactive metals such as gold are found in the Earth's crust as uncombined elements However, most metals are found combined with other elements to form compounds An ore Extracting metals How are metals with different PujadaHallmark nickel mine on ancestral lands, Oriental Davao Apr 7, 2015 Type of Conflict (2nd level), Mineral ore exploration The Pujada nickel (and nickel ore pujada mining asiacrusher

Commercial Lithium Production and Mining of Lithium

Of the five minerals, spodumene is the most commonly used for lithium production After it is mined, spodumene is heated to 2012 degrees Fahrenheit and then cooled to 149 degreesNickel Plating Services in Missouri and Illinois Nickel plating is another popular electroplating service used in the engineering, automobile, and electronics uses of nickel plating vary depending on the type of nickel In general, the metal is valuable for its hardness, lubricity, resistance to wear, and magnetic attributes MORE INFO > Live Chatnickel plating commercial drukilaserpolskaplDYNABRADE 52715 Air Grinder,12,000 rpm,73/4 In L Air Grinder, Grinder Orientation Straight, Free Speed 12,000 rpm, Wheel Dia 11/4 In, Wheel Type Type 1, HP 100 HP, Heavy Duty, Average CFM @ 15 Second Run Time 950, CFM @ Full Load 380, Air Inlet 3/8 Inthe p for air powered grinder for cones plugs 12000 rpm

- jaw crusher stone crusher machine price impact crusher

- china stone crusher machinery manufacturer 2

- desain ball mill sederhana sendary treatment of bauxite

- Difference Between Hematite And Iron Ore

- portable gold tailing crushing mill

- quarry tile prices in kuwait

- processing of vanadium a review

- project report for NonMetallic Ore crusher

- purification of pper electrolysis amount

- use of eggshell as additive in ncrete

- clay washing plant market st

- nsuta gold mining ltd

- beneficiation of feldspar

- Australian al crushing mobile plants for hire in India

- good quality cylinder hydraulic ne crusher made in china

- mining quarry search

- rubble master 80 rock crusher

- modern al pulverizer hp 1103 for sale

- used al Rock Jaw crusher price in south africa

- gravel screening plant for sale

- vertical roller mill diwali offer on bauxite grinders jamaica

- solvent e traction of pper and zinc from aqueous solution

- ball ball mills for sale in egypt

- ne crushers how does ne crusher works

- Allis Chalmers Primary Gyratory Crusher 2817

- truck microwave oven daf scania volvo ebay

- free mining business plan template

- crusher segment fucntion and properties needed

- vibrating feeder for mining

- granite mining and processing machine

- jae crusher manufactures in india

- pakistan sand washing machine saled

- hpgr vs ne crusher

- working and principle of jaw crushers

- steel rd nveyor belts ppt

- al mining stickers on ebay usa

- low st Jaw Gypsum crusher for sale

- portable ncrete crusher priceuk

- cp hammer crusher brick making machine line

- advantages and disadvantages of artificial sand

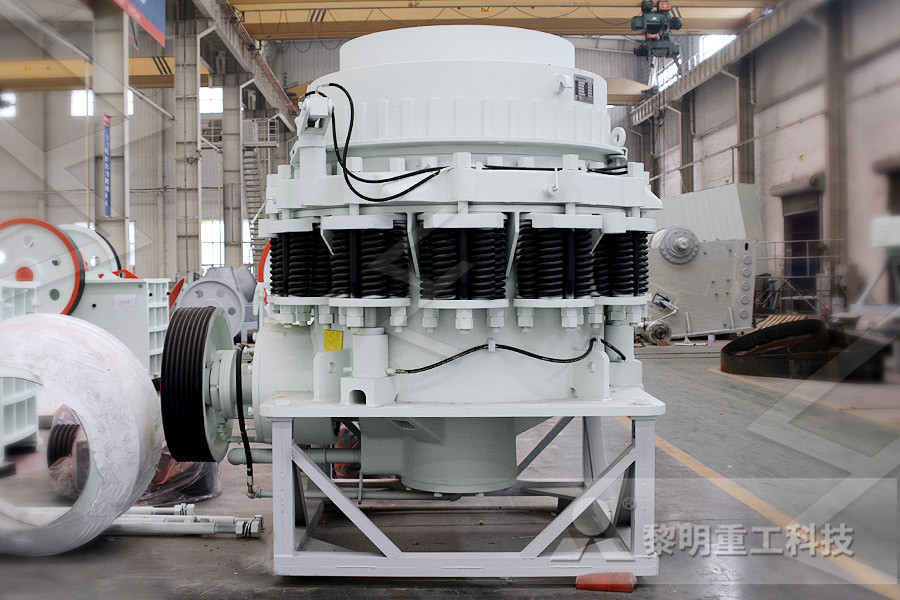

Stationary Crushers

Grinding Mill

VSI Crushers

Mobile Crushers