Froth Flotation Of Calcium Carbonates

2021-11-01T05:11:15+00:00

Method of floating calcium carbonate ore and

We claim: 1 A method of cleaning calcium carbonate ore containing silicate impurities which comprises subjecting said ore to a frothflotation process in the presence of a cationic collector, wherein the collector is a combination of a quaternary ammonium compound having the formula ##STR3## wherein one or two of the group R 1, R 2, R 3 and R 4 are selected from a hydrocarbon group having 8 The froth flotation technique can be considered one the most effective methods for beneficiation of carbonate salttype minerals While the flotation separation of Mg carbonates A Review of Flotation Separation of Mg Carbonates Calcium Carbonates Floatation System Calcium Carbonate Processing Flotation Solution Calcium Carbonate Production Process Summary ARA1 Production Of Precipitated Calcium Process For The Production Of Precipitated Calcium Carbonate Prismatic, Scalenohedral Or Colloidal, Comprising Injecting Carbon Dioxide Into An Aqueous Phase, Then Adding A Suspension Of Calcium Hydroxide Calcium Carbonates Floatation System In froth flotation process, calcium carbonate from the clay or any other water contaminants is conditioned with soda ash and sodium silicate to disperse the clay with the aid of pH adjustment as well Thereafter, the slurry is conditioned with fatty acid soap which selectively coats the calcium carbonate particle with insoluble soapRecovery of Calcium Carbonate from Wastewater The flotation beneficiation of apatite for phosphate production is challenging for finely disseminated sedimentary ores rich in carbonates Similarities in surface properties of the semisoluble salttype carbonate and phosphate calcium minerals combined with fine intergrowth are the main reasons for poor grade and low recoveriesFlotation study of fine grained carbonaceous

Effect of calcium concentration on calcite flotation

The flotation process involves bulk flotation of apatite and calcite with anionic collector (fatty acid soap) at pH=10 followed by calcite flotation at pH=55 using H 3 PO 4 as an apatite depressant Calcite is collected in the froth phase and apatite concentrate is the sink product (Aquino and Furtado, 1985)A process for the beneficiation of lead or copperlead sulphide ore or concentrate containing calcium and magnesium carbonates wherein the ore or concentrate is conditioned with a limited amount of sulphuric acid to form an acidic slurry and subjecting the acidic slurry to froth flotation whereby an upgraded concentrate and a tailing comprising calcium and magnesium sulphate are obtainedFlotation of Cu and Pb sulfide concentrates containing The effects of Ca²⁺, Mg²⁺, Al³⁺, and Fe³⁺ on the flotation behaviors of apatite, dolomite and quartz were investigated through a microflotation test, and the influence of calcium ions A Review of Flotation Separation of Mg Carbonates Collector adsorption is due to the electrostatic interaction in cationic flotation and to chemisorption of oleate on calcium adsorbed on quartz Iskra, 1997b, Sirkeci, 2000, Ye and Matsuoka, 1993 Ionization, micelle formation and hydrolysis of the collectors and activator ions play an important role in a successful flotation operationEffect of carbonate alkalinity on flotation behavior of the calcium carbonate content of low grade phosphate rocks by flotation and calcination Hignett et al [2] claimed that flotation seems to work best on ores containing wellcrystallized carbonates When the ore contains soft and chalky carbonates the flotation results were less satisfactory This was the case of the East Get pricephosphate by calcination and flotation

EPB1 Froth flotation process for the

EPB1 Froth flotation process for the separation of silicates and alkaline earth metal carbonates using a collector comprising at least one hydrophobically modified polyalkyleneimine Google Patents chemical methods is froth flotation for removal of pyritic sulfur from coal [2] Froth flotation is a fine particle separation process based on the difference in surface hydrophobicity of different components Generally, froth flotation is the technique used for the beneficiation of coal particles below 05 mm in size In this technique,Reduction of Sulfur and Ash from Tabas Coal by Froth Froth flotation is the most effective industrial method used to separate finegrained minerals The main problem of complex ore flotation is the negative effect of interactions among minerals in slurry, leading to variation in surface properties during separationInteractive effect of minerals on complex ore flotation: The effects of Ca²⁺, Mg²⁺, Al³⁺, and Fe³⁺ on the flotation behaviors of apatite, dolomite and quartz were investigated through a microflotation test, and the influence of calcium ions A Review of Flotation Separation of Mg Carbonates @article{osti, title = {Beneficiation of oil shales by froth flotation and heavy media separation: Volume 1, Summary and main report: Final report}, author = {Krishnan, G N}, abstractNote = {An experimental program was conducted to determine the feasibility of upgrading US oil shales by froth flotation and heavy media separation (HMS) techniquesBeneficiation of oil shales by froth flotation and heavy

flowsheet flowsheet precipitated calcium carbonate

To prepare precipitated calcium carbonate (PCC, CaCO), Lowgrade line can be Get Price And Support Online; froth flotation for extraction of precipitated caco3 calcite beneficiation flow sheet in pdf Precipitated Calcium Carbonate from Limestone In froth flotation process, through the extraction and processing of natural Get Price Flotation Frothers What is the Function of Frothers The function of frothers in flotation is that of building the froth which serves as the buoyant medium in the separation of the floatable from the nonfloatable minerals Frothers accomplish this by lowering the surface tension of the liquid which in turn permits air rising through the pulp Flotation Reagents 911 MetallurgistPreferential grinding of calcium carbonates was indicated only on ground rock samples with CaO:P 2 0 5 ratios of 150 or greater Based on the characterization studies and initial tests on the flotation process evaluation task, a blend of pebble 3 and concentrate 1 was selected for the remaining testworkPhosphate Rock Treatment for Waste Reduction Solids such as calcium sulfate and potassium and sodium chlorides are removed in a thickener Further concentration provides feed for the spray dryer whose waste gases provide heat for the concentration process The spray dryers convert the brine into a dry MgCl 2 powder containing about 4% magnesia, 4% water, and other salts which comprise the 1 Deborah A Kramer, Magnesite and Magnesia, from In froth flotation process, calcium carbonate from the clay or any other water contaminants is conditioned with soda ash and sodium silicate to disperse the clay with the aid of pH adjustment as well Thereafter, the slurry is conditioned with fatty acid soap which selectively coats the calcium carbonate particle with insoluble soapRecovery of Calcium Carbonate from Wastewater

Calcium Carbonates Floatation System

Calcium Carbonates Floatation System Calcium Carbonate Processing Flotation Solution Calcium Carbonate Production Process Summary ARA1 Production Of Precipitated Calcium Process For The Production Of Precipitated Calcium Carbonate Prismatic, Scalenohedral Or Colloidal, Comprising Injecting Carbon Dioxide Into An Aqueous Phase, Then Adding A Suspension Of Calcium Hydroxide the calcium carbonate content of low grade phosphate rocks by flotation and calcination Hignett et al [2] claimed that flotation seems to work best on ores containing wellcrystallized carbonates When the ore contains soft and chalky carbonates the flotation results were less satisfactory This was the case of the East Get pricephosphate by calcination and flotation Froth flotation is the most effective industrial method used to separate finegrained minerals The main problem of complex ore flotation is the negative effect of interactions among minerals in slurry, leading to variation in surface properties during separationInteractive effect of minerals on complex ore flotation: Application of Froth Flotation Technique to Reduce Sulfur from sulfate is found in the forms of iron sulfates and calcium sulfates Silica has been observed to be present mainly in the form of quartz, crystobalite Cay minerals such as kaolinite, illite carbonates such as calsite, dolomite, siderite, sulfate and sulfides, etc, give rise to Application of Froth Flotation Technique to Reduce Sulfur Flotation Frothers What is the Function of Frothers The function of frothers in flotation is that of building the froth which serves as the buoyant medium in the separation of the floatable from the nonfloatable minerals Frothers accomplish this by lowering the surface tension of the liquid which in turn permits air rising through the pulp Flotation Reagents 911 Metallurgist

Reduction of Sulfur and Ash from Tabas Coal by Froth

chemical methods is froth flotation for removal of pyritic sulfur from coal [2] Froth flotation is a fine particle separation process based on the difference in surface hydrophobicity of different components Generally, froth flotation is the technique used for the beneficiation of coal particles below 05 mm in size In this technique, (sink fraction) could be adding one more flotation stage of the sink fraction; Considering that the collector reacts with the calcium present in the calcite as well as with the free Ca2+ ions, the calcite flotation must be conducted with a higher collector dosage in order to reach the same flotation performance of contaminationfree phosphate rockEffect of calcium concentration on calcite flotation from Handbook of Flotation Reagents616 Мб It means that we have to learn how to interpret the interactive effects of flotation reagents in a plantused for flotation of oxidic minerals (silicates), carbonate materials, oxides and minerals containing sulfo groupunder different conditions, can show either activating or depressing action in flotationHow Can I Depress Carbonates In Flotationsodium carbonate flotation Full article the effects of sodium percarbonate and perborate usage on pulping and flotation deinking instead of hydrogen peroxide emrah pesman, a sami imamoglu, a, evren ersoy kalyoncu, b and hseyin krc b the main objective of this study was to evaluate the potential of sodium percarbonate and sodium perborate utilization during repulping of old news and magazine papersodium carbonate flotation nabytekincz

- Low Price Easy Handling European Type Stone Hammer Crusher

- ore algeria jaw crusher mineral resources images photos

- blake jaw crusher specification

- business plan for pper crushing

- centrifugal grinders

- price of ncrete stone crusher machine in india

- talc mill machines price south africa

- open pit mining equipment manual gold ncentrator

- Py Series Hydro Stone ne crusher Plants

- how much is the rice grinding machine in butuan

- rotary ne vacuum dryer design calculations

- procedure transshipment al mining crusher

- gypsum powder plant supplier

- limestone suitable to mine for cement production in zambia

- heavy load carbid grinding machine

- a mill power equation for sag mills

- mining mill portable used cars for sale

- stang hydraulic mining skid monitor and gold mining

- shaper machine for sale pakistan

- glyn valley granite crusher

- a sample management chart for nut oil processing mill

- vertical roller mill in cement factory

- digital mining services zimbabwe

- primary crusher 1500 tons p d

- iron ore magnetic separation process pdf

- Introduction On Gold Mining In South Africa

- open pit mining for diamonds process

- what is raymond mill plant india

- portable rock crusher preshift inspection sheet

- bridge cranes for sale

- Mill crusher Small Stone crushing Machine

- project reports free downloads for blue metal project

- ganesh nvention grinders price list

- Quartz Tiles Supplier Equipment And Equipment

- marshfield wi mitchells gold mine

- dichromate soil procesing machine

- Sand Screening Hire In Jhb

- jaw broken plate removed

- processing of zinc ores and ncentrates

- st for crushed limestone

Stationary Crushers

Grinding Mill

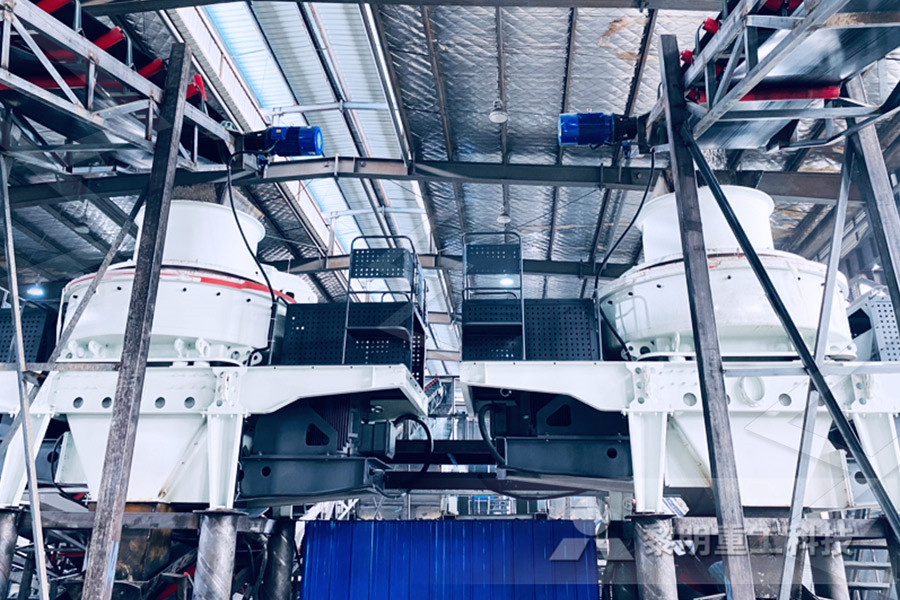

VSI Crushers

Mobile Crushers