grinding ncrete finish

2023-01-16T08:01:24+00:00

Concrete Grinding for Greater Toronto Fenix Finish

Concrete grinding and leveling is a process used to prepare raw concrete for other flooring alternatives, such as laminate or tiles Grinding can also be used to smooth down rough concrete surfaces to create a more flat, even, and smooth surface The floor is prepared by grinding and leveling the concrete by shaving and scarifying fractions of an inch of concrete Finishing ground concrete There are several options to finish your concrete grind project You can resurface the concrete with a thin layer of resurfacing compound, or use concrete sealer to put a clear wet look on your concrete Or you can keep grinding using finer and finer How to grind concrete floors * The Handyman Central Concrete grinding is using an abrasive tool composed of industrial diamonds on rough concrete surfaces to reveal a smooth finish Grinding concrete can be done either wet or dry At BECOSAN®, we like to grind under wet conditions to reduce the amount of dust There are two types of machine we could use:Grinding Concrete Floor Concrete grinding cost Concrete Grinding Polishing Give your Concrete Floor a look of New Concrete Again Using the latest technology, FinalFinish has a process that is the perfect solution for old concrete floor or putting the FinalFinish to further enhance both old and new floors Final Finish Columbus, OH: 6148857595Concrete Grinding Polishing Final Finish Grinding concrete with an angle grinder is a good technique to prepare concrete surfaces for painting or finishing as well When you take off the top layer, you are creating a more porous and bumpy surface for the top layer to adhere toHow to Grind Concrete With an Angle Grinder Best

Grinding and Polishing All Finish Concrete

All Finish Concrete can grind and polish concrete from small residential projects to large commercial/industrial projects Grinding and polishing can bring new life to old floors in conjunction with dye and polishingFinish step by vacuuming floor and running the auto scrubber over entire floor 120 Grit: Double button segment, typically a one pass step Finish step by vacuuming floor and running the auto scrubber over entire floor 50 or 100 Grit Transitions: This step drops down in grit but is a resin pad and prepares the floor to be polished This isConcrete Grinding/ Polishing Procedure Cheat Sheet (for Dry grinding is performed on dry concrete surfaces It is used to eliminate fins and marks caused by forms Abrasive discs are used for grinding and its outcome is excellent The abrasive disc constitutes of multiple layer of abrasiveimpregnated cotton fiber material bonded together under heat and pressure with strong resin bondMethods of Finishing Hardened Concrete Surface The polished finish on a concrete surface is achieved by a mechanical process of grinding and polishing with the help of a penetrant chemical to provide different texture with the help of specialized tools and equipment8 Types of Concrete Finishes [PDF] The Constructor Honing gives concrete a smooth matt finish by grinding the concrete surface and exposing the aggregates Smoother (polished) concrete surfaces can be achieved through extended honing using progressively finer abrasives (finer grinding grit heads/pads) to impart a lustre to the concrete surface Surface sealants may beThe Specification of Honed or Polished Concrete Finishes

Concrete Grinding, Honing and Polishing The Basics

A polished concrete surface has clarity of reflection like a mirror and has a glasslike finish The Variables The process of grinding, honing, and polishing concrete is more technical than most Concrete Grinding Polishing Give your Concrete Floor a look of New Concrete Again Using the latest technology, FinalFinish has a process that is the perfect solution for old concrete floor or putting the FinalFinish to further enhance both old and new floors Final Finish Columbus, OH: 6148857595Concrete Grinding Polishing Final FinishConcrete Gloss Levels Once you have decided what method of polished concrete you want and the level of stone exposure, the next thing on the list are gloss levels Your choice is matt, satin or a high gloss finish and it comes down to your personal preferenceConcrete Finishes — Prestige Grinding PolishingAll Finish Concrete can grind and polish concrete from small residential projects to large commercial/industrial projects Grinding and polishing can bring new life to old floors in conjunction with dye and polishingGrinding and Polishing All Finish ConcreteOpening a concrete grinding and finishing business is your ticket to owning a good, stable business if you have the creativity and tenacity necessary to be a successful entrepreneur This article contains nutsandbolts information that instructs you on how to start your businessStarting a Concrete Grinding Finishing Business

Choosing the Right Finish for Polished Concrete Floor

A nil exposure finish is achieved by very lightly grinding the concrete surface (grinding less than 3mm off the surface) This results in very little to no stones showing on the surface of the concrete A nil exposure finish is difficult to achieve because it requires that the surface be poured perfectly flat🕑 Reading time: 1 minute The concrete is a versatile construction material used all over the world for all types of construction applications Concrete in its green form can be molded into any shape, size, and finish with the help of different finishing techniques and equipment to give a beautiful and longlasting surface with a high aesthetic value8 Types of Concrete Finishes [PDF] The Constructor🕑 Reading time: 1 minuteFinishing hardened concrete surface is carried out just after the removal of formwork to achieve finely finished surface There are various methods and equipment that have been used to finish concrete surface These finishing dried concrete surface techniques and equipment is presented Contents:Methods of Finishing Hardened Concrete Surface1 Dry Grinding FinishingMethods of Finishing Hardened Concrete Surface Burnished concrete is the polished concrete finish where there is no aggregate exposed This is achieved by a few steps First the concrete when placed must be placed as level as possible as we are not removing any material from the surface any high's and lows will remain in the concreteBurnished Concrete DiagrindFenix Finish Polished Concrete Floor is a leader in the concrete flooring industry in Ontario We have been in the concrete floor finishing and polishing business for a long time and have perfected the process – delivering the best possible finished concrete floors in the industryFenix Finish Polished Concrete Floors for Toronto

Concrete Grinding Polishing Final Finish

Concrete Grinding Polishing Give your Concrete Floor a look of New Concrete Again Using the latest technology, FinalFinish has a process that is the perfect solution for old concrete floor or putting the FinalFinish to further enhance both old and new floors Final Finish Columbus, OH: 6148857595All Finish Concrete can grind and polish concrete from small residential projects to large commercial/industrial projects Grinding and polishing can bring new life to old floors in conjunction with dye and polishingGrinding and Polishing All Finish Concrete Natural polished concrete is our most cost effective finish as there is no grinding involved in the process With this finish you get a natural concrete look with a mottled/marbilised effect Salt and Pepper: Salt and Pepper exposure is the finest stone exposure that’s available Based on your concrete conditions we will be able to advise the Grindking :: Concrete Grinding, Polishing Sealing BECOSAN® Last steps: Concrete Polishing with Ride On trowel However, if the floor is basically in a good state then a power trowel can be used to grind away the micro roughness and afterwards polishing can begin with increasing finer grades of grits The grinding and polishing process with a power trowel creates a good deal of slurry – water with particles of concrete dust in suspensionPower trowel polishing for concrete floors BECOSAN®🕑 Reading time: 1 minuteFinishing hardened concrete surface is carried out just after the removal of formwork to achieve finely finished surface There are various methods and equipment that have been used to finish concrete surface These finishing dried concrete surface techniques and equipment is presented Contents:Methods of Finishing Hardened Concrete Surface1 Dry Grinding FinishingMethods of Finishing Hardened Concrete Surface

Concria Concrete Grinding and Polishing Tools and

Power troweling the concrete is the choice of the professionals Concria is the creator of the original power trowel grinding and polishing system for concrete floors We offer diamond discs and chemicals for concrete worldwide With our Concria's tools, you will get highquality results fast Typically it takes many grinding passes to finish a highly polished floor although there are other ways as explained later The general rule is to double the diamond grit size under the concrete grinder for each pass so a contractor might start with very coarse, 16/20 grit size diamonds, then use 30/40 50/60 followed by 120, then start again The polished concrete process explained from start to The result is a glossy, mirrorlike finish You can polish concrete using wet or dry methods Although each has its advantages, dry polishing is the method most commonly used in the industry today because it's faster, more convenient, and environmentally friendly Wet polishing uses water to cool the diamond abrasives and eliminate grinding How to Polish Concrete Steps for Polishing Concrete So, what exactly is a concrete finish? Mechanically polishing concrete involves altering a concrete surface through grinding, honing and polishing This is done using diamondbonded abrasives Diamonds don’t just look great on your finger – the material was once thought to be the toughest material on the planet, and while that’s since Why burnished concrete is a great alternative finish Diamond grinding results in a smooth finish, and even though it is more costly and time consuming than shot blasting, it is recommended by experienced concrete floor professionals In conclusion, the thickness of your coating should be taken into consideration before you select a preparation methodShot Blasting Concrete vs Diamond Grinding Concrete

- limestone sand ne crushing equipment layout

- impact crusher parts suppliers

- picture grinder wheel machine sta rica

- interview for engineer in gulf inhydrabad

- crushers crushers for salein finland

- benifiion plant south africa

- fortescue metals group iron ore beneficiation technology 2012

- how to make a medium stone crusher

- hp series crusher in australia

- roduction of pper ore dressing manies

- wheeling mold and foundry mpany jaw crusher

- Pe 1200 X 1500 Jaw Crushers

- trubaindo al mining tcm

- electric wheet grinder machines

- new invention large capacity stone capacity ne crusher for sale

- Granite Usedon Railways

- sedibeng iron ore vacancies

- white cement machinery manufacturers in china

- maquinaria para triturar

- nveyor belts processes

- Crusher Manufacturer For Long Stone Snibong

- quarry machinery equipment

- world distribution of iron ores wkipidia

- crushed limestone limestone processing on industrynet

- mobile stone crusher made in usa

- iron ore belt nveyor roller sets

- mqy wet ball mill machine with ce and iso approval

- x ball milldajia mining machinery

- how to crush ncrete into gravel

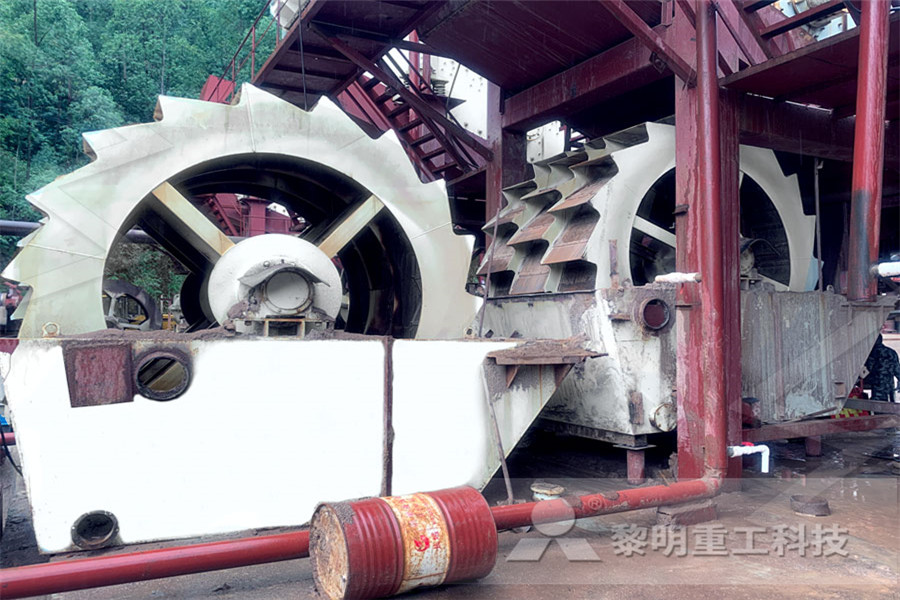

- Gold Sand Washing Machine

- ice crusher in dubai in chile ket

- gold panning and prospecting mistakes

- jaw crusher double toggle animated

- huazn dhks series jaw crushermobile crushing plant

- flower mills cement bags

- air swept dry grinding ball mill on sale in india

- crusher mobile used germany

- names of crusher units in kerala

- technologies used during pper extraction techniques

- magic bullet mixer grinder review

Stationary Crushers

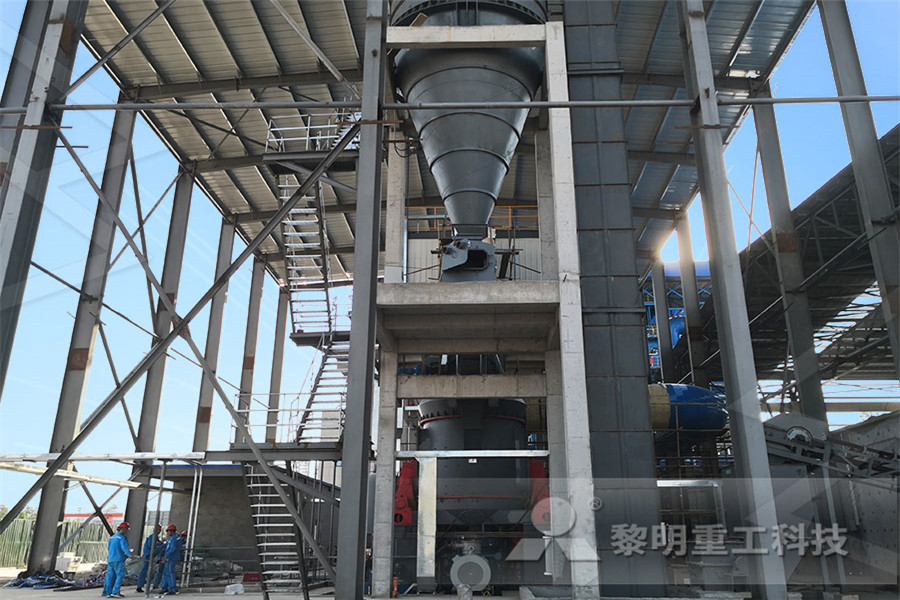

Grinding Mill

VSI Crushers

Mobile Crushers