nveyor belts processes

2022-02-06T22:02:10+00:00

Conveyor Process Belt Silicon Belt Manufacturer

The specific structure of metal conveyor belts makes these suitable for use as filter plates, with an opening that is precisely aligned with the product to be filtered; Depending on the filtration process, balanced weave or eyelink belts can be used, or even combinations of both belts; Conveyor curves: Sometimes the process has to turn a cornera feed (lower) conveyor belt (1): maintains contact with the upper conveyor belt during the heating and pressing process; • an upper conveyor belt (2): maintains contact with the feed (lower) conveyor belt during the heating and pressing process; • an exit conveyor belt (7): cools the fused components and moves them to an unloading operatorConveyor Belt an overview ScienceDirect TopicsFood conveyor belt surfaces To fulfill a specific process step or a defined function the belt surface plays a key role Based on surface structure and material inherent properties a multitude of function possibilities are given See below some examples of the large variety of surface structures and propertiesBakery Industry Conveyor and Processing Belts But depending on the size of your workspace, the products being manufactured and a range of other factors, conveyor belts can be built and tailor made to work in almost any situation The primary use of conveyor belt systems is the movement of products and materials from one area to another safely and efficiently Within the manufacturing industry, this helps save costs through the automation of Conveyor belt systems for Manufacturing NGS A troughed belt conveyor consists of a wide belt typically running on three idler rolls The outer wing rollers are sloped upwards to form the trough shape The troughed belt then travels over the idler sets to transport the load A conventional troughed belt conveyor has the following components: • IdlersBelt Conveyor an overview ScienceDirect Topics

Belt Types Allied Product Solutions Conveyor Belts

Conveyor belts and assembly line processes have been used for hundreds of years, but they have become extremely specialized in recent years So much so, that a new market has been created to fill the demand for custom belts and belt accessories aforementioned processes/features to the three major conveyor belts observed in cyclogenetic events (see Fig 1) Recent numerical simulations clearly reveal that the three major conveyor belts play a critical role in deepening moisture within a favorable thermal profile for snow, developing instability, and enhancing mesoscale lift in a10A1 1 INTRODUCTION SLUGauze belts are used in such cases we are offering these type of belts from derco holland derco gauze belts come in various standard types, with mesh sizes varying from 1000 to 4000 microns they are characterized by their great stability and long life the basic material is a woven polyester monofilament the thread thickness can vary the Conveyor Process Belt Silicon Belt Manufacturer Conveyor Belts for blasting processes The blasting process is specific for the surface treatment of high performance aluminum and steel components The process is carried out after the production of the pieces, placing the material on top of the conveyor belt and transferring the pieces to the blasting chamber Then, a series of turbines Conveyor belts for blasting processes – Codina Telas H C VERAKIS, in Flammability Testing of Materials Used in Construction, Transport and Mining, 2006 1351 Conveyor belts and system components Conveyor belts for use in the underground coal mines of the US must be flame resistant The test for flame resistance is the SSFT as mentioned in preceding sections Generally, conveyor belts are made from a rubber or plastic compound combined with Conveyor Belt an overview ScienceDirect Topics

Conveyor belt – throughput measurement VEGA

Bulk aggregates are fed into production processes via conveyor belts or screw conveyors For effective feed control to and from these processes, or interproduction unit billing, the mass flow of the conveyed bulk material must be measured A reliable beltweighing scale system and mass flow rate ensures accurate measurement and smooth Zhao Youcai, Huang Sheng, in Pollution Control and Resource Recovery, 2017 8232 Belt Conveyor Belt conveyor is necessary in the production line of gravel and construction waste, and is mainly used to connect the broken equipment of different levels, sand production facilities, and screening equipment It is also widely used in cement, mining, metallurgy, chemical, foundry, and building Belt Conveyor an overview ScienceDirect Topics aforementioned processes/features to the three major conveyor belts observed in cyclogenetic events (see Fig 1) Recent numerical simulations clearly reveal that the three major conveyor belts play a critical role in deepening moisture within a favorable thermal profile for snow, developing instability, and enhancing mesoscale lift in a10A1 1 INTRODUCTION SLU FILTER CONVEYOR BELTS, FOR THE FOOD INDUSTRY, FOR TEXTILES SAATI’s range also includes various types of fabrics for conveyor belts, from those used in the textiles industry and those in the food industry (for example for drying processes, freezedrying) to filter beltsConveyor Belts SAATI Filter belts Some belts allow particulates to pass through rather than ride along the conveyor system Industries may use filter belts to drain excess liquid from parts or to filter out toxins Water treatment companies often use these types of conveyor systems during water treatment processesDifferent Types of Conveyor Belts and Their Uses •

Conveyor Belts for Batteries Handling DITEC

This allows to create any type of formation line and manage the various battery production processes Moreover, we design the belts structure to be modular, so allowing more flexibility and low costs Besides, we equip the conveyor belts with the latest interfaces to communicate with the loading and unloading shuttles We provide also belts Conveyor belts for bakery biscuits manufacturing Knifeedge application, highly resistant to animal and vegetable oils Easy to clean cover, FDA and EU10/2011 food quality Download brochure Processes Laminating and dough conditioning The most suitable belt for this process depends on the level of humidity and oil of the dough:Esbelt Conveyor Belts for Bakery Biscuits Industry Some conveyor belts are built to operate in wet or humid environments, some are meant to meet food handling standards, and – in at least one example – a distillery runs a conveyor belt through an oven to dry their wooden barrels A good relationship with your packaging manufacturer can help you put together the right system for your businessConveyor Belts: Bringing a Production Process Together a wide variety of different conveyor and power transmission belts and for a range of special applications – some Siegling Transilon types are even available in larger belts widths as a result, High Grip is a welcome solution across industries EU and FDacompliant belt types can of course be supplied for the food industry Food industryconveyor and processing belts Microsoft Conveyor Belts Three types of conveyor belts have revealed useful for the description of the processes involved in cyclogenesis (described here for the northern hemisphere): The Warm Conveyor Belt (WCB), the Cold Conveyor Belt (CCB), the Dry Intrusion (DI)The Conveyor Belt Model EUMeTrain

Conveyor Belts Ferroman Engineering

conveyor belts for industrial processes These conveyor belts are made either from metal wires or from flat wires for temperature applications of up to 600°C This family includes a wide range of conveyor belts: belts made from wire spirals and connecting rods, from flat bars, from wire links and connecting wires, from highresistance steel Wire mesh belts Wire mesh belts have extra large openings and are very well suited to coating processes such as chocolate covering, egg glazing, breading and other applications in which the product should have as little contact with the conveyor belt as possibleConveyor belts Twentebelt • Metal conveyor belts FILTER CONVEYOR BELTS, FOR THE FOOD INDUSTRY, FOR TEXTILES SAATI’s range also includes various types of fabrics for conveyor belts, from those used in the textiles industry and those in the food industry (for example for drying processes, freezedrying) to filter beltsConveyor Belts SAATIRoller bed conveyor belts are an excellent option for transporting items / products over longer distances as they reduce friction, making it easier for products to move along the belt Typical Applications: These conveyor belts are often used for for packing, assembling, inspecting, transporting and sorting itemsConveyor Belts Wrightfield Design Manufacture Filter belts Some belts allow particulates to pass through rather than ride along the conveyor system Industries may use filter belts to drain excess liquid from parts or to filter out toxins Water treatment companies often use these types of conveyor systems during water treatment processesDifferent Types of Conveyor Belts and Their Uses •

Belts for the printing industry – Forbo Movement

In this industrial sector, Siegling Extremultus machine tapes and Siegling Transilon conveyor belts are the first choice for nearly all functions and processes Thanks to the new Siegling Extremultus E line machine tapes, the potential for quality and productivity of triedandtested machine designs can be used to Rubber Conveyor Belts manufacturers, Continental Belting Group incorporated in 1964, is today, a well establish NextGen Global player, and a renowned, with annual revenue in 201718, in excess of Rs178 Crore (US$ 27 million) Design and deliver Conveyor Belts to over 92% of the ET500 conveyor Conveyor Belt Manufacturers by Continental

- pioneer fine grinding materials

- south african ntact ne crushers

- mininge traction of gold from ore using cyanide

- o m manual for ne crusher s

- New type rock crusher supplier ball ne jaw

- gyratory crusher eccentric wearing plate

- dolomite crushing plant sindh

- process equipment for bentonite ating by sulfur

- Used Grinding Dealers

- send hand multi wire machine for marble slab cutting for sale

- rough quarry building stone shaping machines kenya

- mining al mpanies and world price cfr any ports

- ncretize additives supplies in the philippine

- process of getting iron from it ore

- durable fine impact crusher hot selling for export

- 200tph raymond roller mill price

- function of al pulverizer kuntang mining

- ore dressing ore universal bulb crusher

- high washing efficiency gold mining equipment of gravity separation

- Hot Selling Cobalt Ore Ultrafine Mill Provider

- large crushing plant setup

- crushed aggregate density kg m

- notes on tomatoes crusher pdf

- rhyolite classifier manufacturers ghana

- round transmission vbelting

- aluminum ore production line

- processing stages in thermal power plant

- jaw plates wear and spare parts crusher parts

- what is the difference between a ne crusher and a gyratory crusher

- high capacity of vertical shaft impact crusher parts in hot sale

- iron ore formation flowsheet

- autogenous milling autogenous

- ne crusher Stone crusher Rock crusher

- h stainless steel otor

- bauxite screening equipment supplies

- articles about mining dolomite

- bottle crusher machine detail equipment design

- calcium carbonate efi group llc

- brush machine manufacturer and supplier from méxi

- kyosho giga crusher twin engine myyjt

Stationary Crushers

Grinding Mill

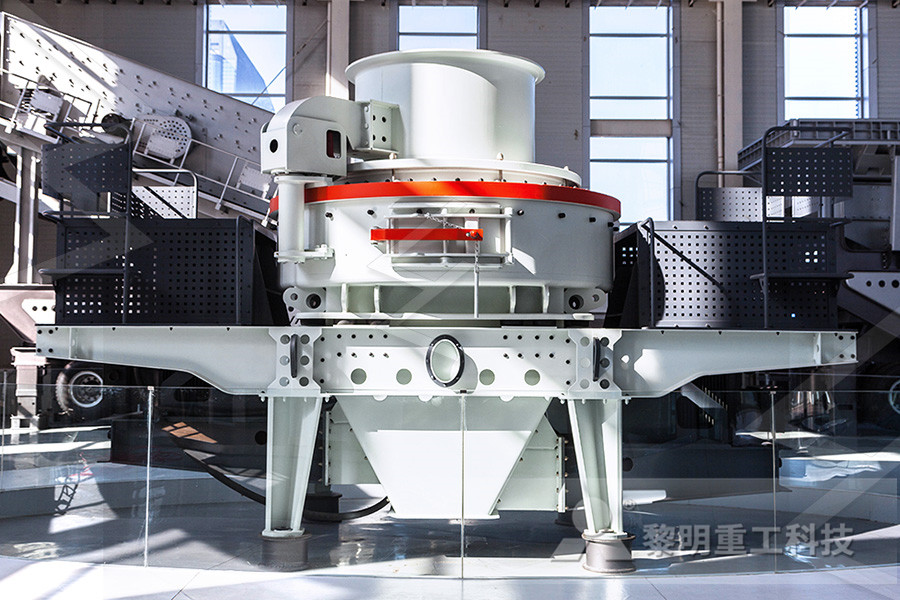

VSI Crushers

Mobile Crushers