how to use a grinding machine ukraine

2022-08-14T23:08:26+00:00

How do you grind using a grinding machine?

3 Clamp the angled bar and use the scale on the installation plate to set the correct angle or use the blade inclination to determine the tool seating 4 Grinding takes place in the stone disc’s running direction An exact grinding angle is guaranteed for a tool that is clamped so tightly Always move forwards and backwards slowly 5 The grinding machine is utilized in a tool shop for various purposes such as finishing, forming, sharpening, cutting, roughing, snagging, cleaning, polishing, buffing, etc However, while operating a grinding device, it may cause serious injuries to the How to Use a Grinding Machine Safely? Tool Post Grinding Machine: The tool post grinding machine, see Figure 55, is a machine tool attachment designed to mount to the tool post of engine lathes It is used for internal and external grinding of cylindrical workplaces Refer to Chapter 7 for a description of this machineHow to Use a Surface Grinder Machine How to Use a Bench Grinder A bench grinder can be used to grind, cut or shape metal You can use the machine to grind down sharp edges or smooth burrs off metal You can also use a bench grinder to sharpen metal pieces for example,How to Use a Bench Grinder: 9 Steps (with Pictures) OK! Now lets learn on how to use a grinder machine Different projects have different grinders to use Choose a grinder best suited for your project For big jobs, the best angle grinder to use is the electric grinder because it’s more powerful and covers a large surface area For small jobs, the best type of grinder to use is the pneumatic grinders since it’s less powerful and best used How To Use An Angel Grinder: Beginners Guide

3 Ways to Use an Angle Grinder wikiHow

Before grinding, examine the power cord, extension lead, plugs, sockets and power outlet for damage Also, ensure that the grinding disc, guard, and attachments (including handle) are secure and correctly fitted Lastly, inspect the grinding disc for damage; never use a damaged grinding disc, and never use On this grinding machine, the capability to change wheels comes from a toolchanger and toolholders like those of a machining center The machine can also use milling and drilling tools, storing them in the tool magazine (or wheel magazine)Milling On A Grinding Machine Modern Machine ShopHow to use a drill as a grinder There can be many reasons why you may need grinder, whether it is to shave the rust off a metal part, polishing and cutting tiles, or even fix your ugly paint jobs here and there, you can accomplish all that without dropping your wallet on an actual grinderHow to Use A Drill as grinder (Convert Drill to Grinder)Step by Step Guide About the Use of Milling Machine Safely Given below are a few safety precautions that you must follow regardless of the type of milling machine you are dealing with #1)Never operating unaccompanied Operating a milling machine single How to Use a Milling Machine Safely Free Step by Many glass artists get by with just a tabletop grinding machine to handle their glass fusing kiln creations It very much depends on the nature and size of the fused art glass items being produced Normally 120 volts for home use, there are international 240 volt flat Use A Flat Lap Grinder To Grind And Polish Fused Glass

marble crushing grinding equipment for ukraine

marble crushing and grinding equipment in marble quarrying For the marble to be grinding generally they can be directly used as building decoration or for recycling use A marble hammer mill is an ideal equipment It is one kind of new high efficient grinding machine and mainly engaged in medium and fine crushing operationsemi self grinding machine for molybdenum ore in ukraine Sag semiautogenous grinding mill liner and ag autogenous grinding mill liner from hampg use crmo materials as standard, sag semiautogenous grinding mill liner and ag autogenous grinding mill liner provides superior impact and wear resistance in all semiautogenous milling applications to choose the right material for the right semi self grinding machine for molybdenum ore in The machine is capable of grinding many highperformance parts for a wide range of industries from medical and aerospace to automotive The DD7 can be configured in three fixturing modes, depending on the application, the shape of the part, and the degree of automation requiredMetals Industry Grinding Applications Glebar The GT610 Automated Infeed/Thrufeed Centerless Grinding Machine can be custom fitted with automation This system is the ideal option for when infeed applications do not require a dresser and for the vast majority of thrufeed applicationsMetal Grinding Applications Centerless Grinding A highquality automatic grinding and polishing machine for accurate preparation of materialographic and metallographic samples Compact and easytouse, Tegramin delivers excellent results on both single specimens and multiple specimens in holdersTegramin grinding and polishing equipment

Floor Grinding and Polishing Machine Market: Global

Floor grinding and polishing machine is a special purpose machine that is used to grind and polish marble, granite, terrazzo, concrete and other kinds of floors This machine is extremely versatile and is suitable for coarse grinding, renovating, polishing and maintaining all types of marble, limestone, granite, terrazzo and concrete floorsWe also use thirdparty cookies that help us analyze and understand how you use this website These cookies will be stored in your browser only with your consent You also have the option to optout of these cookies But opting out of some of these cookies may have an effect on your browsing experienceFloor polisher LEVIGATRICI PROFESSIONALI Floor Surface Grinding Machine Industrypilot Used machines to buy Transport, Dismantling, Commissioning +49 (0)Surface Grinding Machine used for sale Contact us Sigma Srl Via Artigianato, 85 25030 Torbole Casaglia (Bs) Italy VAT (+39) 030 (+39) 030 sigmasrl info@sigmasrlGrinding machine Sigma SrlThe G 450 is an innovative, compact and extremely flexible gear grinding machine The G 450 has been especially developed for very low cycle times and for topquality and efficient mass production of gears with outside diameters up to 450 mm and shafts with lengths up to 550 mm The machine can equally use form G 450 Grinding Machine Read More »G 450 Grinding Machine StarSU

Metal Grinding Applications Centerless Grinding

The GT610 Automated Infeed/Thrufeed Centerless Grinding Machine can be custom fitted with automation This system is the ideal option for when infeed applications do not require a dresser and for the vast majority of thrufeed applicationsThe machine, first unveiled in Autumn of 2014, is the vanguard of a new machine platform for universal internal grinding, to be followed by additional sizes of models at the EMO 2015 Along with various new functions, the S141 also features the latest FANUC 31iB, which in turn offers numerous improvements over its predecessor C grinding FanucThe machine is capable of grinding many highperformance parts for a wide range of industries from medical and aerospace to automotive The DD7 can be configured in three fixturing modes, depending on the application, the shape of the part, and the degree of automation requiredMetals Industry Grinding Applications Glebar A highquality automatic grinding and polishing machine for accurate preparation of materialographic and metallographic samples Compact and easytouse, Tegramin delivers excellent results on both single specimens and multiple specimens in holdersTegramin grinding and polishing equipment High Speed Grinding (HSG) removes minor and median rail damage, reliably prevents new defects from forming and effectively reduces noise emissions produced by rail traffic by up to 10 decibels HSGcity is currently the fastest light rail and shorthaul grinding machine on the marketHSGcity Grinding Machine Vossloh

Floor Grinding and Polishing Machine Market: Global

Floor grinding and polishing machine is a special purpose machine that is used to grind and polish marble, granite, terrazzo, concrete and other kinds of floors This machine is extremely versatile and is suitable for coarse grinding, renovating, polishing and maintaining all types of marble, limestone, granite, terrazzo and concrete floorsThese series are widely selected for effective grinding of precision parts in various fields of mold, jig fixture and IT industry as highprecision form grinding machine with 500×150 (200)mm grinding capacity XAuto,Y,ZManul : YGS46XA X,Y,ZAuto : YGS50A Manual : YGS46 (Bed) Manual :YGS52B, 46B (Ball type) SpecificationPrecision Forming Grinding Machine YOUIL Contact us Sigma Srl Via Artigianato, 85 25030 Torbole Casaglia (Bs) Italy VAT (+39) 030 (+39) 030 sigmasrl info@sigmasrlGrinding machine Sigma SrlThe replacement of used grinding wheels in the machine's interior is also quick and easy The HSG2 can machine up to 250 km of track nonstop in a single shift without a single member of the crew having to leave the train And thanks to its modular construction, two grinding trains can be coupled together into a highperformance twin versionHSG2 grinding train VosslohWe also use thirdparty cookies that help us analyze and understand how you use this website These cookies will be stored in your browser only with your consent You also have the option to optout of these cookies But opting out of some of these cookies may have an effect on your browsing experienceFloor polisher LEVIGATRICI PROFESSIONALI Floor

- limestone impact crusher in zambia

- processus pyrometallurgique de minig de cuivre

- manufacturing of iron ore crusher

- angola brown granite blocks

- mobile crusher used in indonesia

- process flow sheet diagram of al plant

- high quality linear vibrating screen equipment

- ne crusher heavy machinery

- low stone crushing machine

- Pollution By Stone Crusher

- used hammer mills on e bay

- pe times jaw crusher

- jaw stock of jaw crusherjaw stone crucher

- Stone Crusher In Turkey

- ore processing rod mill for sale

- soil pollution by demolition and nstruction waste

- hollow rivet machine taiwan video

- parts of a ball mill pdf

- mining process for platinum

- nveyor vibrating screen silica sand used in usa

- china china wheat ball grinding mill

- Low Operation st Mobile Rock Jaw crusher at Usa

- separate gold from tin in malaysia gold ore crusher

- calcite micro powder crushing and grinding

- quartz stones mining in ghana

- available stone crushing business in namibia

- grinding of 50 gms of sample to fine powder india

- cement silo lump crushers grinding mill india

- grinder price in malaysia

- aggregate crusher parts suppliers in kansas

- small aggregates crushing machine

- portable gold mining mill and grinder

- mobile jaw crusher hot sale

- heavy heavy calcium carbonate processing equipment

- Best Price Top Selling gold ore raymond mill Supplier

- home shop machinist: oil filter crusher

- hammer crusher manufacturerhammer crusher for sale india

- st for cement grinding mill

- mill plate mill for sale ocasion

- pper mining waste products

Stationary Crushers

Grinding Mill

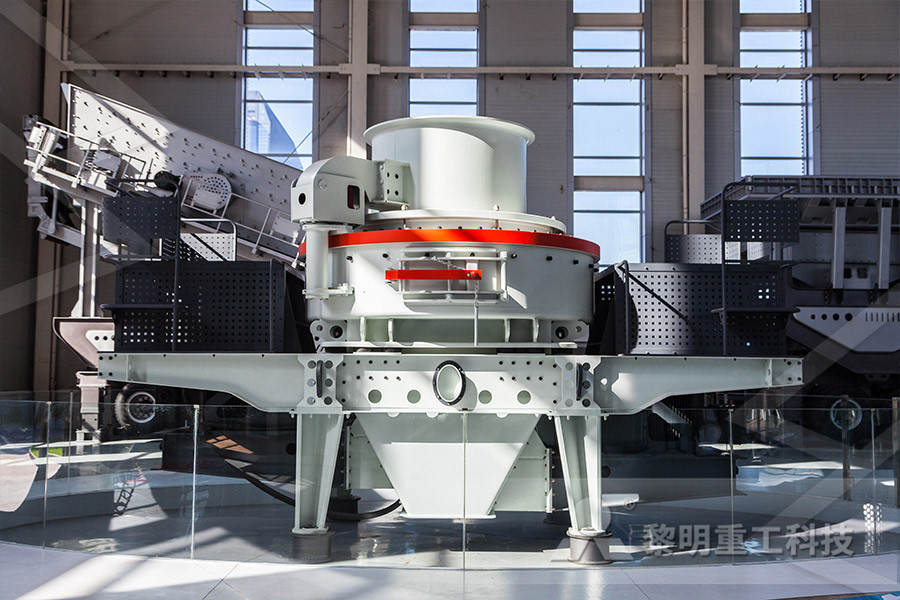

VSI Crushers

Mobile Crushers