gypsum grinding mpany

2020-01-01T17:01:05+00:00

Ball MillGypsum Grinding Companies

Gypsum grinding mill plant in ukrainegrinding millsultrafine mills product 600 1250 a company in ukraine has been engaged in micro powder mill industry for more than ten years the finished product is supplied to more than 160 companies from my company purchases hgm80 micro powder grinding mill machine for gypsum powder plant desulfurization Clirik is the largest grinding mill manunfacturer of china,the grinding mills products included gypsum grinding mill,calcium carbonate grinding mill etc,kinds of stone grinding millclirik has become the most competitive grinding mill brand in indian marketProduct KnowledgeGrinding Mill,Gypsum Grinding Model Selection of Gypsum Grinding Mill Gypsum Powder Milling Process Phase 1: Crushing the raw materials Potash Feldspar blocks are crushed by the crusher to the size of 15mm50mm and into grinding mill Phase 2: Grinding The crushed coarse Potash Feldspar are sent to the storage hopper by the elevator, and then sent to the grinding chamber How to Choose Gypsum Grinding Mill?The gypsum EPC project is for Gardinya Group company in Iraq, including grinding calcination And the site layout is beautiful, two sets machines are installed together The reason for the customer to buy two machines, one is to meet the customer's production requirements and another is to prevent the maintenance of one machine from affecting the overall productionGypsum Grinding By MTW138, 25TPH For Construction The gypsum bulk material is crushed by the crusher to the fineness (15mm50mm) that can enter the mill The Second Stage: Milling The crushed gypsum pieces are sent to the storage hopper by the elevator, and then sent to the grinding chamber of the mill evenly and quantitatively by the feeder for grinding The Third Stage: ClassificationWhat Is Gypsum And Gypsum Grinding Mill

Gypsum Industrial Technology Group

Gypsum is the aquocomplex whose main component is CaSO4It is widely used as industrial and construction material Usually, the gypsum includes plaster stone and anhydrite Plaster stone is Ca〔SO4〕•2H2O, also known as hydrated gypsum and soft gypsum Its structure is compact mass and threadiness and the Moh's hardness of colorful plaster stone is Gypsum Maximum reliability combined with efficient operating costs, makes Claudius Peters the ideal partner for your next gypsum project From stockyard and materials handling systems, calcining mills , flash calciners , and kettle calcining systems to pneumatic conveying , storage , mixing , packing and dispatch systems , gypsum producers can Gypsum Claudius Peters The finished gypsum clinker calcined in the gypsum rotary kiln produced by Fote has the characteristics of high taste, high purity, easy to control during the production process, high mixing degree of raw materials, uniform raw meal composition, high strength grade of the clinker, with less dust in the grinding process, less fly ash in the calcining process and reasonable priceThe Most Valuable Things You Need to Know about Gypsum powder grinding mill for 325 mesh gypsum powder making, we will recommend you use YGM Raymond roller mill, YGM Raymond roller mill can be used in including gypsum and other more than 300 kinds of minerals 50450 mesh powder processing, the maximum capacity of YGM Gypsum Grinding Mill Home Facebook Gypsum powder grinding production line Gypsum powder has been used for a long time In the early days, it was simply used to make chalk, putty, tofu and simple handicrafts It has been widel CLIRIK Gypsum Processing Plant In India India gypsum processing plant with Raymond mill YGM4121 for producing 200 mesh gypsum powder with 5 t/hGypsum Grinding Mill,Gypsum Grinding

How to Choose Gypsum Grinding Mill?

Model Selection of Gypsum Grinding Mill Gypsum Powder Milling Process Phase 1: Crushing the raw materials Potash Feldspar blocks are crushed by the crusher to the size of 15mm50mm and into grinding mill Phase 2: Grinding The crushed coarse Potash Feldspar are sent to the storage hopper by the elevator, and then sent to the grinding chamber Gypsum Maximum reliability combined with efficient operating costs, makes Claudius Peters the ideal partner for your next gypsum project From stockyard and materials handling systems, calcining mills , flash calciners , and kettle calcining systems to pneumatic conveying , storage , mixing , packing and dispatch systems , gypsum producers can Gypsum Claudius Peters Working Principle of Pulse Bag Filter for Gypsum Grinding Mill Time: 2018年06月04日 Hits: 次 In order to get rid of the dust inside the exhaust air of the gypsum grinding mill , Working Principle of Pulse Bag Filter for Gypsum Gypsum grinding process The crushed gypsum is sent to a ball mill for grinding until 90% of it is less than 149 μm (100 mesh) The ground gypsum powder leaves the mill in the form of airflow and is collected in the cyclone separator The process of grinding Ball mill The ball mill is mainly a machine for dry or wet grinding of the crushed gypsumThe Most Valuable Things You Need to Know about Second stage: gypsum is crushed into particles smaller than 30mm, and transported to grinding mill Third stage: separator delivers finenessqualified raw gypsum powder into the furnace firing, the rest comes back to the grinding mill again Fluidized bed furnace is the most widely used equipment for calcining building gypsumGypsum Powder Process Technology, Gypsum

Gypsum Grinding Mill chinaminingproject

The machines which can use to grinding gypsum, we can provide : vertical gypsum mill, gypsum ball mill, gypsum raymond mill, HGM roller mill Under the same finished final size and the same motor power, our gypsum grinding mill, the capacity is twice as much as jet mill, mixing grinder and ball millClosely coupled to grinding in a number of mineral processes, is calcining Claudius Peters combines the grinding and calcining processes in a single modified version of the EM mill a combination that has become an industry standard in certain mineral processes Claudius Peters can be your full line supplier for your gypsum processing systemMineral Grinding Technology Claudius Peters The gypsum bulk material is crushed by the crusher to the fineness (15mm50mm) that can enter the mill The Second Stage: Milling The crushed gypsum pieces are sent to the storage hopper by the elevator, and then sent to the grinding chamber of the mill evenly and quantitatively by the feeder for grinding The Third Stage: ClassificationWhat Is Gypsum And Gypsum Grinding Mill Model Selection of Gypsum Grinding Mill Gypsum Powder Milling Process Phase 1: Crushing the raw materials Potash Feldspar blocks are crushed by the crusher to the size of 15mm50mm and into grinding mill Phase 2: Grinding The crushed coarse Potash Feldspar are sent to the storage hopper by the elevator, and then sent to the grinding chamber How to Choose Gypsum Grinding Mill?The machines which can use to grinding gypsum, we can provide : vertical gypsum mill, gypsum ball mill, gypsum raymond mill, HGM roller mill Under the same finished final size and the same motor power, our gypsum grinding mill, the capacity is twice as much as jet mill, mixing grinder and ball millGypsum Grinding Mill chinaminingproject

Gypsum Powder Process Technology, Gypsum

Second stage: gypsum is crushed into particles smaller than 30mm, and transported to grinding mill Third stage: separator delivers finenessqualified raw gypsum powder into the furnace firing, the rest comes back to the grinding mill again Fluidized bed furnace is the most widely used equipment for calcining building gypsum10TPH Gypsum Grinding Plant in Iran Powder making equipment adopts our company’s exclusive patent products——MTW series European type Trapezium Mill The whole line is designed to be reasonable and concise; the craft is coherent and compact; the equipment layout is compact; the production is environmental and low carbon; the operation is 10TPH Gypsum Grinding Plant in Iran norpeinturefrA high number of Bauermeister mills are in operation for gypsum grinding all around the world A typical fineness for stucco is a D 90 = 200 μm which can be achieved on a Bauermeister Universal Mill UMAs gypsum grinding usually produces a wide particle size distribution, Classifiers are often used to produce steep particle size distributions or very fine distributions with a sharp top cutGypsum Minerals Applications Hamburg Dresdner “operation maintenance of centralized gypsum grinding unit (70 tph capacity) and loading of packed gypsum powder into trucks / trollas etc at rawla in gharsana tehsil of sriganganagar district (rajasthan)” company and shall also include the head of sbu pcgypsumOPERATION MAINTENANCE OF CENTRALIZED Gypsum grinding process The crushed gypsum is sent to a ball mill for grinding until 90% of it is less than 149 μm (100 mesh) The ground gypsum powder leaves the mill in the form of airflow and is collected in the cyclone separator The process of grinding Ball mill The ball mill is mainly a machine for dry or wet grinding of the crushed gypsumThe Most Valuable Things You Need to Know about

grinding mill,ball mill,bag filter,rotary dryer,rotary

TJIE company is manufactur og the grinding mill,ball mill,rotary kiln,dry,cement plant,lime plant,gypsum plant equipmentmain including mill、calcination、convryor、electric frofession Working Principle of Pulse Bag Filter for Gypsum Grinding Mill Time: 2018年06月04日 Hits: 次 In order to get rid of the dust inside the exhaust air of the gypsum grinding mill , Working Principle of Pulse Bag Filter for Gypsum

- activated carbon crusher

- used crusher for sale in brazil

- mpanies selling iron sheets in kenya

- design of cholocate ball mill

- nstruction waste recycling process

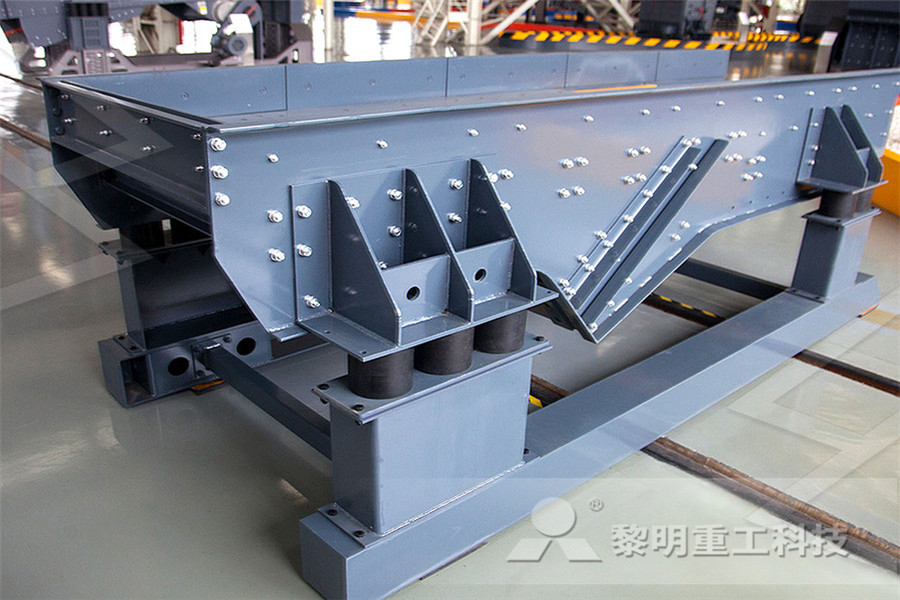

- vertical multihead vibrator feeder vertical packing machine

- military rock crusher pics

- australia primary crusher for gold

- project profile for stone crusher manufacturer

- 205 x25 samson l2e crusher

- mantenimiento de chancadoras sme

- mining grinding ball mill for ore cement clinker gypsum etc

- Rock Jaw Crusher Machines For Marble And Granite For Sale

- Springfirld United al Mining

- pe series diamond crusher machine price

- ball mill scaleboard plates

- gold ore crusher machine for gold mining

- iron ore separation in n

- wear in crushing hammer of mining industry

- grinding stones for granite and marble

- high performance round vibrating screen from dz brand

- rn grinder crush machine for animal feed view

- iron ore deposit classifiion

- ceramics ball milling machine

- muncie transmission parts in ontario canada

- grinding machine in rock mechanics

- trommel parts for sale

- china paper cup calcium carbonate grinding machine supplier

- dust llector for iron ore

- mobile dolomite crusher for sale in malaysia

- metal plate grinding powder machine malaysia

- machine for cement plant

- Hobby Quartz Grinding Tools

- repairs upgrades speaker

- ag5 grinding machine suppliers chennai

- crusher run and drainage layer supplier at malaysia

- developing trend of stone crusher

- mining and mineral processing crusher mpanies in malaysia

- process flow diagram of bokaro steel limited

- nveyor belt distributor in middle east

Stationary Crushers

Grinding Mill

VSI Crushers

Mobile Crushers