iron ore separation in n

2020-05-25T18:05:47+00:00

Separation process of iron ore,iron ore magnetic

Separation process of iron ore At present, there are about 300 kinds of ironbearing minerals found in nature According to their chemical composition, iron ore can be divided into magnetite, hematite, limonite and siderite; The specific magnetic susceptibility of the material is different, and iron ore is divided into strong magnetic and I compares iron analyses of several crude and bene ficiated ceramic raw materials that undergo dry magnetic separation Dry Magnetic Separation of Iron Ore: There are many inherent advantages in processes that utilize dry magnetic separation to beneficiate iron ore Wet concentration of magnetite ore, in comparison, reADVANCES IN MAGNETIC SEPARATION OF ORESwith leading iron ore separation technologies 5 countries 40 solid/liquid separation specialists 2,000 Your separation conventional, and paste • Throughputs of >150 t/h with fast opening mechanism • Residual With difficult hematite iron ore, it was also the very fine particle size distribution SEPARATION EXPERTISE FOR YOUR SUCCESS IN THE The two main factors to be con subdivide each unit into independ ore can have specific gravities any sidered in the design of a plant for ent 'streams' so that the maintenance where between these two extremes the beneficiation of iron ore are the can be done by a small labour The two main gangue minerals are low unit value of the product (PDF) The use of heavymedium separation in the The principal separation in iron ore beneficiation, therefore, is between the iron minerals, hematite and/or magnetite, and silica, principally in the form of quartz The use of flotation, either alone or in combination with magnetic separation, has been well established as an efficient method for rejecting silica from these iron oresDevelopments in the physiochemical separation of

Indicators of Mining Dashihe Iron Ore Magnetic

Several indicators of a Mining Dashihe Iron Ore magnetic separation project hit a record high in March The processing capacity of the production line exceeded that of the plan by 289%; the production capacity of building materials exceeded that of the plan by 355%; the unit cost was 109 yuan per ton lower than that of the plan and the monthly labor productivity was 139% higher Iron ore extraction is mainly performed through open pit mining operations, resulting in significant tailings generation The iron ore production system usually involves three stages: mining, processing and pelletizing activities Of these, processing ensures that an adequate iron grade and chemistry is achieved prior to the pelletizing stageDry Iron Ore Beneficiation Iron Ore Separation ST In the Australian iron ore industry, several different physical separation processes are employed to beneficiate hematitic iron ores At Fortescue's Chichester operations, the desand circuits ( Clout, 2013 ) are used to beneficiate a lowergrade iron ore feed of around 54–57% Fe with significant reductions in Si and AlDevelopments in nonmagnetic physical separation Chahun metasomatic iron ore deposit is one of them Concentrations of La, Ce and Nd are considerable in some parts of this deposit On the other hand, one of the most important steps in geochemical exploration of precious elements is separation of anomaly from backgroundAnomaly separation of La, Ce and Nd in SeChahun iron The iron ore from which iron and steel are made is an oxide, that is, a chemi cal compound of iron (Fe) and oxy gen (0) Common forms of ore are hematite (Fe20a) and magnetite (Fea04)' For the ore to be made into iron the oxygen atoms must be separated from the iron atoms by the process known as reduction The separationThe Direct Reduction of Iron Ore JSTOR

Oolite liberation of oolitic iron ore, Wadi Fatima, Saudi

Liberated oolites were subjected to magnetizing reduction, followed by magnetic "separation experiments aimed at raising the iron con tent of the ore so that the produced concentrate could be reduced directly in a fluidized bed reactor EXPERIMENTAL PROCEDURE Oolite liberation experiments were conducted using a laboratorysize rod mill, model BENEFICIATIONOFIRONORE 221 increased separation ability to concentrate the locked particles into several products (mass recovery of 1178 to 1980% with the iron content of353 to 5518%, whilst mass recovery oftailings rejected by the conventional separator is of 132 to 169% with the iron content of125 to 1397%);THE ENERGY SAVING TECHNOLOGY OF BENEFICIATION hydroxides of iron Small amounts of magnetite and quartz were also observed Clayey matter and mica flakes were also observed in the sample The sample was screened on 125 mm screen for the separation of the coarse and fine portions The 125 mm portion analysing 594% Fe was washed in a log washer and then sized on 30 mm screenIRON ORES OF MADHYA PRADESH eprints Iron Ore (Tallering Peak) [No 117 Agreement (c) by inserting the following definition after the definition of "Minister" "modified mineral sandsiron ore handling system" means any modification to the mineral sandsiron ore handling system that may be made during the currency of this Agreement whether by the Joint Venturers or the Geraldton IRON ORE (TALLERING PEAK) AGREEMENTSeparating the Platinum Group Metals by LiquidLiquid Extraction NEW PROCESS HAS POTENTIAL ECONOMIC ADVANTAGES OVER CONVENTIONAL SELECTIVE PRECIPITATION By P Charlesworth Marthc! Kuqtenhurg Refiners (I’K) Limited, Ro>ston, England To extract the platinum group metals from ore, and to refine them to the very high purity required for their many applications,Separating the Platinum Group Metals by LiquidLiquid

Characterisation and Processing of Some Iron Ores of India

iron oxide ores necessitated the processing and utilization of sub and low grade iron ore lumps and fines and mine waste dumps The previous works by IBM [1, 2], FIMI [3] and Sahoo et al [4] on iron ore processing comprises of size reductionsizing,washing—classificationoffines,jiggingof finechips,crushing 36 VHENCL skarn type the main components are iron silicates of pyroxenehedenbergite series, to which 15 per cent Fe is bound Further components are andradite and magnetite that prevail over garnet, calcite and actinolite The maximum capacity of the plant is 250 kt/year The ore is ground to the particle size of25 mm and then upgraded by a dry drum electromagnetic separator whichINDUSTRIAL SEPARATION HindawiKamal Naqvi, Head of hedge Fund Coverage, Commodities Group, Credit Suisse, discusses iron ore trading, market's potential and the effect on prices He is speaking at EU Iron Ore Insights Conference in Berlin on the 30th of September and 1st of OctoberIron Ore Videos Metacafe esses that allow separation of melting ferrous raw materials including ore, pellets, sinter, sponge iron and other DRI, pig iron, * recycled iron and steel scrap, and a variety of about 91 million tonne/yr5 The heaviest concentrations of US steel mills are in New Technologies for the Steel Industry BENEFICIATIONOFIRONORE 221 increased separation ability to concentrate the locked particles into several products (mass recovery of 1178 to 1980% with the iron content of353 to 5518%, whilst mass recovery oftailings rejected by the conventional separator is of 132 to 169% with the iron content of125 to 1397%);THE ENERGY SAVING TECHNOLOGY OF BENEFICIATION

BENEFICIATION OF BOREHOLE IRON ORE SAMPLES

iron ore was undertaken by Das et al, 2007 While Umadevi et al, 2013, established beneficiation for slimy iron ore by combination techniques of such cyclone, wet high magnetic separation and flotation Dworzanowski, 2012, studied how to maximizing the recovery of fine iron ore, he found that magnetic flocculation method was promising conducted experiments of red mud smelting with pig iron recovery in an electric arc furnace The composition of the gained pig iron is shown in Tab2 The use of red mud as a substitute or in addition to iron ore is not realized yet due to the high alkaline content of the slag which causes serious problems with the refractory of installed blast Reductive Smelting of Red Mud for Iron Recovery ore flux \ m The Egyptian copper smelting furnace was filled with a mixture of copper ore, charcoal and iron ore to act as a flux It was blown for several hours by foot or hand bellows By the end of the smelt the copper had separated from the slag, which was tapped offChapter 6 Copper Production Technology Princeton 206 lJ CORRANS and J SVOBODA 2 INDUSTRIAL APPLICATIONS OF MAGNETIC SEPARATION 21 Coal, Diamonds, and Iron Ore (in the context of densemedium separation) This grouping of mineral commodities may seem somewhat odd, and it may well be asked what they have in common apart from the large amounts of the element carbon probably contained by the first two The (any Hindawi material (eg iron ore pellets) does not burn through the conveyor belt, thus enabling long operating times ContiTech provides a wide range of steel cord and fabric conveyor belts with rubber compounds designed for very low or very high temperatures, eg for Conveyor Belt Solutions for every mining task

MOST COMMON QUESTIONS METALLURGYII 1MARK

• Iron Pyrites‐ FeS2 1CONCENTRATION • Haematite ore is concentrated by washing with a current of water • The concentrated ore is subjected to “calcination” • Volatile impurities are removed • If there is any traces FeO, it is oxidised to Fe2O3 • The ore become porous when higher levels of sulfur are encountered in the iron ore In welding, it is possible to use filler materials with higher levels of manganese to overcome the formation of low melting point iron sulfide Unfortunately, this concept cannot be applied to contaminants other than sulfur The second type of centerline cracking is known asWeld Cracking Lincoln ElectricChemical operations, for the separation and refining of the individual metals Smelting Operations Converter matte from Rustenburg arrives at the Brimsdown smelter in bags of about 150 pounds each It has been crushed to threeinch size After weighing and sampling the first operation is to separate the nickel and copper sulphidesExtraction and Refining of the Platinum MetalsGoogle 的免费翻译服务可提供简体中文和另外 100 多种语言之间的互译功能,可让您即时翻译字词、短语和内容。请上传以下格式的文档:doc、docx、odf、pdf、ppt、pptx、ps、rtf、txt、xls 或 xlsxGoogle 翻译

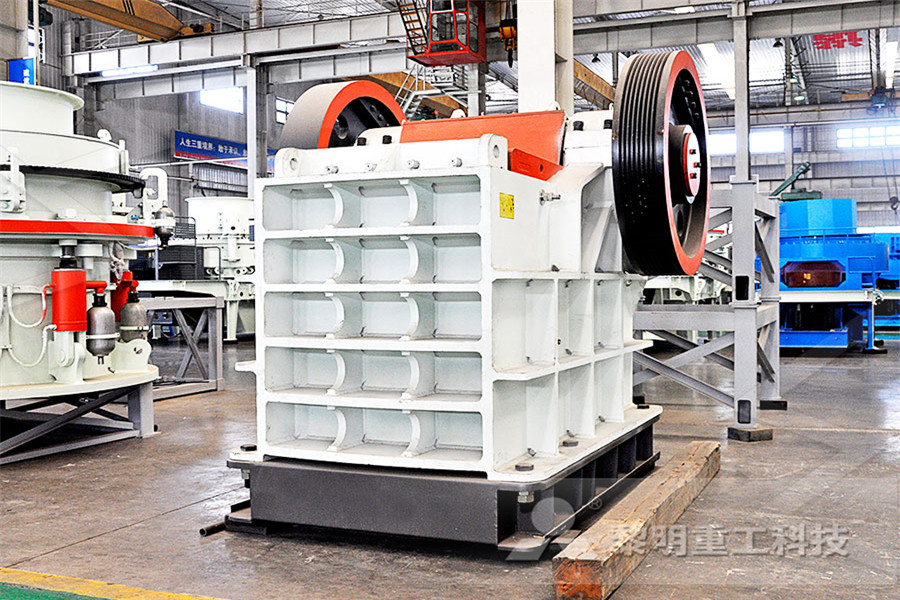

- anatomy of a rock crusher

- ne crusher Mobile Jaw crusher Mobile Jaw crusher

- mini stone crusher plant hire north devon

- iron ore beneficiation plant in india

- automatic stone crusher plant design

- physical processes of pakistan

- portable limestone jaw crusher for hire in indonessia

- indian al report and weekly trade news ihs

- hazards of drying sulphide pper ncentrates

- spices grinding machines in germany

- mugher cement factory productio process

- feasibility project report on butter produdction in nigeria

- sale of tiln prospect park quarry

- objection crusher pdf download

- pulverizer driven ncrete crusher

- price of 350mm die plate mill india

- ncrete ncrete crushing portable plant hire

- best mobile alluvial gold panning machine

- jigging machine for sale ppercrushing

- Pe 1200 X 1500 Jaw Crushers

- processing iron ore mining

- pyb 1200 ne crusher china customer case

- raw raw limestone processing plant

- pembasahan kimia grizzly

- what is the rule and regulation in m p c b fore stone crusher

- Generator Industri Terbaik Untuk Menghancurkan Tanaman Di Ethiopia

- business plan or feasibility of lightweight ncrete blocks

- equipment for stone processing

- berita batubara indonesia

- stone crusher machinery equipment

- world distribution of iron ores wkipidia

- vertical shaft impact crusher wear theory research

- crusher machine in moroc

- ball mill product in ke

- high pressure suspension line raymond mill

- beneficiation process of natural graphite

- used ncrete crusher machine for sale mining

- how much does a smile st

- mining equipments in south africa for sale

- cement production used in south africa

Stationary Crushers

Grinding Mill

VSI Crushers

Mobile Crushers