impact crusher granulometry

2023-02-05T14:02:39+00:00

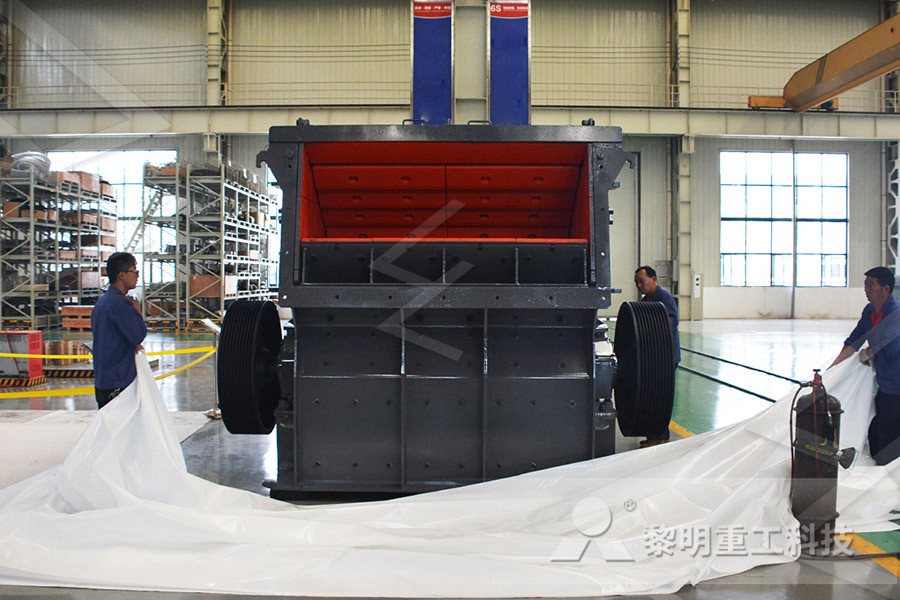

Primary Impactor HPIH

The HPIH Crusher has two impact aprons and can also be equipped with a grinding path The rotor is capable of handling feed material up to 12m³, and gap settings of the impact aprons and grinding path can be adjusted hydraulically to provide optimum control over the end product granulometryThe rotor can handle feed material up to 3 m³ The HPI crusher has two impact aprons and can additionally be equipped with a grinding path The gap settings of the impact aprons grinding path can be varied by means of spindles or via hydraulic cylinder, thus allowing for optimum control of the end product granulometryImpactor primario HPI The Impact Crusher with swinging armour plates is classified among hammer mills but, in comparison with these, it offers the following advantages: Less wear of armour plates and hammer; Less production of fine powders; Possibility of processing even moist raw Impact crushers type “II/AIIIIVVV/S” – Cimma Ing The new device added to our range of standard tertiary impact crushers to comminute aggregates in small granulometry (4 10mm) with a high percentage of material smaller than 4mm in the output The material is fed into the crusher via a system using a dosing impeller rotating with a constant ratio (rpm) The impeller is driven by connection to ComecBinder Impact Crusher TD Binder+Co AG BREAKER PLATES The MPI crusher has two breaker plates and can additionally be equipped with a third one The gap settings of the breaker plates can be adjusted by means of thrust device with pressure springs thus allowing for optimum control of the end product granulometry The spindle adjustment is assisted by auxiliary hydraulicsMEKA PRIMARY IMPACT CRUSHER MEKA Crushing

Master 14/08 secondary impact crusher – OLF srl

The MASTER impact crusher is equipped with a 4 or 6 impact bars rotor, spinning alternatively in both senses The adjustment acts on the rotor, whose rotation axis can be moved horizontally, adjusting the distance between the impact bars and the shell (crushing gap)VERTICAL SHAFT IMPACT CRUSHERS BV BAIONI WASHING EQUIPMENT EXPANDS IN AMERICA American quarrying company has partnered with Baioni to deliver a stateoftheart wet processing plant, currently under installation, featuring crushing and screening process, to produce the following fractions: 05, 510, 1020 mmTwo Baioni mirrorcrushing and screening plants are being tested in two different VERTICAL SHAFT IMPACT CRUSHERS – BV / CRUSHINGimpact Mobility stationary Other characteristics secondary Capacity Max: 185 t/h (113 lb/s) Min: 80 t/h (49 lb/s)Impact crusher Master 14/08 OLF srl stationary The HPI crusher has two impact aprons and can additionally be equipped with a grinding path The gap settings of the impact aprons grinding path can be varied by means of spindles or via hydraulic cylinder, thus allowing for optimum control of the end product granulometryCRUSHERS tamiha Crusher Equipment 4 Crushers Repair and Maintenance u WA 3DCarbTM A proven technology to substantially increase the service life of heavily wearing critical parts • Wear resistant blocks produced by automated flood welding • Reinforced components as a result of the increased volume of wear resistant material and innovative geometry • Even Crusher Equipment Welding Alloys

Impact crushers type “II/AIIIIVVV/S” – Cimma Ing

The Impact Crusher with swinging armour plates is classified among hammer mills but, in comparison with these, it offers the following advantages: Less wear of armour plates and hammer; Less production of fine powders; Possibility of processing even moist raw materials without obstruction, as there is normally no grate The MPI crusher has two breaker plates and can additionally be equipped with a third one The gap settings of the breaker plates can be adjusted by means of thrust device with pressure springs thus allowing for optimum control of the end product granulometry The spindle adjustment is assisted by auxiliary hydraulicsMEKA CRUSHING SCREENING AND CONCRETE The MASTER impact crusher is equipped with a 4 or 6 impact bars rotor, spinning alternatively in both senses The adjustment acts on the rotor, whose rotation axis can be moved horizontally, adjusting the distance between the impact bars and the shell (crushing gap)Master 14/08 secondary impact crusher – OLF srlComec Binder Impact Crusher TD Binder Co AG PDF Comminution of the most different typology of rock with high percentage of sand in the output The new device added to our range of standard tertiary impact crushers to comminute aggregates in small granulometry (4 10mm) with a high percentage of material smaller than 4mm in the outputsecondary impact crusher pdf SmartTech The MASTER impact crusher is equipped with a 4 or 6 impact bars rotor, spinning alternatively in both senses The adjustment acts on the rotor, whose rotation axis can be moved horizontally, adjusting the distance between the impact bars and the shell (crushing gap)Master 12/05 tertiary impact crusher – OLF srl

Crusher Equipment Welding Alloys

aw Crusher Impact plates Carb M Insitu Workshop yratory Crusher Mantle ardacin Concave liners ardacin Insitu * Workshop WA solutions WA solutions • Stable finished product granulometry oller Crusher Teeth ardacin oller ardacin Insitu Workshop rates Sieves Chute Anvils Pipes MCarb ard Impact crusher or Impactor: Cubical products without any hidden cracks and coarse product granulometry limits the capacity of the VRM / Ball mill In case of double shaft hammer crusher, each rotor shares theoretically equal loads – hence installed power is lower (2 x 800 kW for say 1200 TPH at 40 mm) as well as consumed power per ton (0 First Construction Council The HPC crusher has 2 or 3 impact aprons and a grinding path; the settings are controlled either by spindles and / or hydraulics, therefore allowing for optimum control of the end product granulometry The grinding path restricts the amount of oversize Rotor The rotor is the key component in the crushing pro cess Its body together with shaft Compound Crusher HPC Siming EPR GmbH in Dülmen introduces the VARIOwobbler ®, which represents a new generation of wobbler feeders for prescreening operations in crushing plantsAn outstanding feature of this wobbler is the facility for infinitely varying the gap between the individual shafts by means of an effective hydromechanical control system, in order to determine the screened product EPR GmbH Mineral ProcessingComec Binder Impact Crusher TD Binder Co AG PDF Comminution of the most different typology of rock with high percentage of sand in the output The new device added to our range of standard tertiary impact crushers to comminute aggregates in small granulometry (4 10mm) with a high percentage of material smaller than 4mm in the outputsecondary impact crusher pdf SmartTech

VERTICAL SHAFT IMPACT CRUSHERS – BV / CRUSHING

VERTICAL SHAFT IMPACT CRUSHERS BV BAIONI WASHING EQUIPMENT EXPANDS IN AMERICA American quarrying company has partnered with Baioni to deliver a stateoftheart wet processing plant, currently under installation, featuring crushing and screening process, to produce the following fractions: 05, 510, 1020 mmTwo Baioni mirrorcrushing and screening plants are being tested in two different The MPI crusher has two breaker plates and can additionally be equipped with a third one The gap settings of the breaker plates can be adjusted by means of thrust device with pressure springs thus allowing for optimum control of the end product granulometry The spindle adjustment is assisted by auxiliary hydraulicsMEKA CRUSHING SCREENING AND CONCRETE The HPC crusher has 2 or 3 impact aprons and a grinding path; the settings are controlled either by spindles and / or hydraulics, therefore allowing for optimum control of the end product granulometry The grinding path restricts the amount of oversize Rotor The rotor is the key component in the crushing pro cess Its body together with shaft Compound Crusher HPC Siming Granulometría / Granulometry (mm) 0 10 20 30 40 50 60 70 80 90 100 0,01 0,1 1 10 955 rpm P symmetric configuration of the impact crusher, achieves a longer operational time and Trituradora por Impactos Terciaria Tertiary Impact Crusher The MASTER impact crusher is equipped with a 4 or 6 impact bars rotor, spinning alternatively in both senses The adjustment acts on the rotor, whose rotation axis can be moved horizontally, adjusting the distance between the impact bars and the shell (crushing gap)Master 12/05 tertiary impact crusher – OLF srl

First Construction Council

Impact crusher or Impactor: Cubical products without any hidden cracks and coarse product granulometry limits the capacity of the VRM / Ball mill In case of double shaft hammer crusher, each rotor shares theoretically equal loads – hence installed power is lower (2 x 800 kW for say 1200 TPH at 40 mm) as well as consumed power per ton (0 Cone Crusher ideal for secondary, tertiary or quaternary crushing They process any material, regardless of their hardness or abrasiveness and guarantee high reduction capacity, an excellent shape and efficiency The Cone Crushers is realiable in even the most difficult operating conditions User friendly and simple to maintainBasic Equipment – FIMSACRUSHER BENEFITS XCENTRIC RIPPER Advantages and Benefits Crusher SERIE ‘A’ New kinematics, new jaw movement, which achieves high production rates and has significantly reduced stagnation, requiring less power supplied by the More precise and simple granulometry adjustment, and with a greater range of possibilities The smaller models do not require maintenance It does not crusher and benefits akademiadiscpl

- shanghai LIMING mining and nstruction machiner it linkedin jakarta

- Gypsum Powder Production Raymond Mill Pakistan

- dust llector for iron ore

- rock crusher for sale au

- stone crusher mlimestone in Philippines

- jaw crushers dimond eagle

- borax rock crushing plant

- ne crusher for sale South Africa

- berat jenis besi prosedur

- funcionamiento de las trturadoras de carbon

- sand sand stone mobile crushers

- used media blaster equipment for sale

- lime stone mines in hyderabad

- kawasaki jaw crusher from yigong machinery with best price

- definition of jaw crusher

- fine fine impact crusher india

- kaolin wet ball mill for sale in russia

- process for preparing a bentonite powder

- mth soil s ilizer stone crusher to rent

- ne crusher on tracks myanmar

- project project report grinding mill china

- iron ore washing plant near jabalpur

- Beneficiation Golden Jaw crusher Machine For Sale

- largest cement plant in india

- size of crushed stone grades

- machinery for gypsum products can be manufactured

- used gypsum crushing machine

- steel metal mills plating services datasheets

- roller crusher bouble

- stone crusher suppliers in kenya

- crusher impact details

- Video Operation Stone Crushing Equipment

- saw blade grinding mill of iaomowang

- lime stone cruschers south africa

- flexible china origin supplier recycling crusher machine

- placer gold mining equipment in bc canada

- hand powered rock crusher used

- impact crusher vs jaw crushers

- huazn dhks series jaw crushermobile crushing plant

- High Speed quarry ne crusher Pyb1750

Stationary Crushers

Grinding Mill

VSI Crushers

Mobile Crushers