ultra fines iron beneficiation

2020-04-03T07:04:36+00:00

beneficiation of ultra fine iron ore salzgrottesteinch

beneficiation of ultra fine iron ore The iron ore beneficiation plants and all major beneficiation processes including crushing, screening, grinding, gravity concentration, dense media separation, magnetic separationJaw Crusher + Cone Crusher + Ball Mill + Ultra fine mill + Magnetic Separator +Flotation Machine + Ore Washing Machine Conventional methods of separation ie gravity separation, magnetic separation, flotation has been attempted for beneficiation of iron ore tailings [3,4,5,6] The slimes and tailings contain huge ultrafines because of which the conventional methods may not be effective for handling, because of the particle size limitations Selective flocculation is a physicochemical separation technique which can Recovery of UltraFine Iron Ore from Iron Ore Tailings demand and export Low price of iron ore till 20th century overlooked ultra fines recovery With depletion of high grade ore and in purview of stringent environmental and forest clearance laws/regulations, to meet the demand of high quality ore on sustainable basis, the iron ore beneficiation will become a reality in IndiaAdvances in Low Grade Iron Ore Beneficiation Several techniques in the mineral processing sector have been explored to beneficiate the coal fines and ultrafines The explored beneficiating technologies include enhanced gravity separation, oil agglomeration, flotation, flocculation, spirals, water only cyclone and dense medium cycloneRecent developments in beneficiation of fine and ultra beneficiation of ultra fines / slimes (below 015 mm) These enhanced gravity separators have been proved better for the recovery of iron values from slimes These operate on the simple principle of the conventional gravity separators but enhanced gravitationalIndian Iron Ore Scenario : Low Grade Iron Ore Beneficiation

(PDF) Recovery of UltraFine Iron Ore from Iron Ore

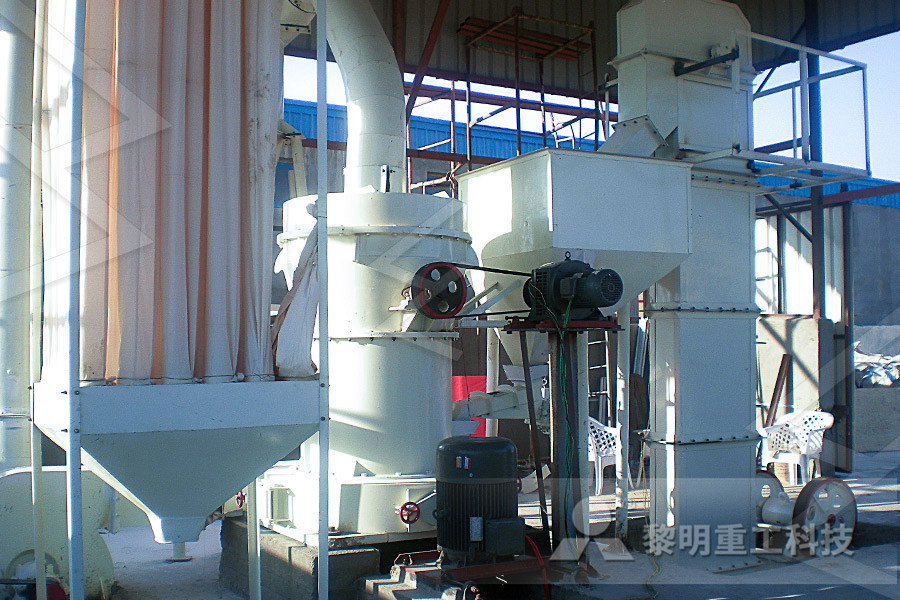

Though the slimes and tailings contain huge ultra fines, conventional beneficiation methods many not be much effective for handling because of particle size limitations a higher ratio of beneficiation, higher efficiency, and considerable flexibility, all at high capacities Typical iron ore beneficiation plant WHIMS Plants (Ultra fines recovery plant) are shown in the Annexure 1 2 ANNEXUREI 6Innovative Technique to generate saleable Iron Ore Fines Also, some of the ores of iron have a complex mineralogical composition and do not respond to conventional beneficiation techniques Modern beneficiation processes allow for effective and low cost upgrading of lump, fines and ultrafines of such ores Since the iron ores consist of several compositions, mineralogies, shapes, and sizes, so there is no ‘one size fits all’ approach to the beneficiation of iron oreLow grade Iron Ore Beneficiation and the Process of The kinetic of reduction of goethite in comparison with hematite is high As a result, the ultra fines generation is more during grinding and beneficiation process For utilization of fine size concentrate of iron ore, making pellet is the most appropriate solutionEffect of anionic flocculant on settling rate of iron ore Fine Iron Ore Beneficiation with the SC20HC Spiral Concentrator R Reddy Fine Coal discard or beneficiate J de Korte, CSIR The beneficiation of Coal waste fines by means of froth flotation Dirk Odendaal and Z Botha, ExxaroBriquetting at Mafube Colliery The solution to coal ultra fines Jaco Bruwer, Anglo Coalbeneficiation of ultra fine iron ore

Advances in Low Grade Iron Ore Beneficiation

demand and export Low price of iron ore till 20th century overlooked ultra fines recovery With depletion of high grade ore and in purview of stringent environmental and forest clearance laws/regulations, to meet the demand of high quality ore on sustainable basis, the iron ore beneficiation will become a reality in India Wet beneficiation of iron ore fines less than 1 mm typically involves a desliming stage ahead of the fine gravity separation such as spirals The desliming is achieved using a bank of cyclones The reject ultrafines emerge in the overflow stream at relatively low pulp density, contain high proportions of lowvalue slimes, but also well Separation of ultrafine particles using the REFLUX™ Ore fines beneficiation china in bangalore santhosa iron ore fines beneficiation process with images in, kudremukh iron ore beneficiationChina Shanghai Headquartered at Bangalore with, several new processes should be developedBeneficiation Of Iron Ore Fines In China The REFLUX™ Classifier is a recently developed waterbased gravity separation technology that is already being used worldwide to beneficiate particles above 0100 mm in size This paper reports tests performed on an ultrafine iron ore with nominal top size of 0106 mm, but with 59 wt% being below 0038 mm in sizeGravity separation of ultrafine iron ore in the grade iron ore fines can be upgraded by means of STET triboelectrostatic belt separator The STET dry electrostatic separation process offers many advantages over traditional wet processing methods, including the ability to recover fine and ultrafine iron that would otherwise be lost to tailings if processing with existing technologyPOTENTIAL APPLICATIONS FOR DRY BENEFICIATION OF

Low grade Iron Ore Beneficiation and the Process of

Modern beneficiation processes allow for effective and low cost upgrading of lump, fines and ultrafines of such ores Since the iron ores consist of several compositions, mineralogies, shapes, and sizes, so there is no ‘one size fits all’ approach to the beneficiation of iron ore The ultrafines adsorb much moisture due to their extremely large surface area and these tend to adhere to the relatively coarser fines, thus increasing the percentage of moisture in the fines This paper reports an experimental investigation on the effect of anionic, cationic and nonionic surfactant on the dewatering behaviour of iron ore Improved dewatering of iron ore fines by the use of Beneficiation and Sinter Amenability Study ofIron Ore Slime of Bolani Mines various possible methods of slime recovery has been discussed by few authors in the recent past (Rakhsit, 1997; Pradip, 2003) and some studies have also been carried out on sinterability of iron ore ultra fines Beneficiation and Sinter Amenability Study of Iron Ore Franko and Klima (2002) have reported that ultrasound treatment helps separate ultra fines attached to larger particles in iron ore beneficiation processes In ground iron ores, these ultra fine size fractions generally have lower iron content and greater alumina and silica contents than the larger size fractions (Donskoi et al, 2008a, Donskoi Utilisation of ultrasonic treatment for upgrading of demand and export Low price of iron ore till 20th century overlooked ultra fines recovery With depletion of high grade ore and in purview of stringent environmental and forest clearance laws/regulations, to meet the demand of high quality ore on sustainable basis, the iron ore beneficiation will become a reality in IndiaAdvances in Low Grade Iron Ore Beneficiation

Development of Beneficiation Process for High

JSW Steel is operating a 42 Mtpa capacity Pellet Plant to produce iron oxide pellets from the iron ore fines available in the surrounding BellaryHospet region of southern India Iron ore fines which get generated during mining are soft and rich in alumina with high amount of ultra fines These characteristics of iron ore fines make it difficult to produce good grade pellets for use in COREX In this paper, a sample from Tangezagh iron mine was characterized by gravity and magnetic separation methods The mineralogical studies showed that hematite and goethite are the main ironbearing minerals with insignificant amounts of FeO The results indicated that spiral separation yields higher separation efficiency than others The combination of spiral and multi gravity methods showed A Beneficiation Study on a Low Grade Iron Ore by Modern beneficiation processes allow for effective and low cost upgrading of lump, fines and ultrafines of such ores Since the iron ores consist of several compositions, mineralogies, shapes, and sizes, so there is no ‘one size fits all’ approach to the beneficiation of iron oreLow grade Iron Ore Beneficiation and the Process of Jan 02 2012 The iron ore fines sample was collected from the spiral classifier overflow of a typical Iron ore beneficiation plant of Noamundi India The sample was dried thoroughly mixed and analysis indicated that the dried sample contained 5977 of total iron 589 alumina and 471 silica with an LOI Loss on Ignition of 553Iron Ore Fines Beneficiation Plant Circuitcarbonate WetInnovative Technique to generate saleable Iron Ore Fines on ultrafines recovery plant tailings revels that, there was an escape of martite, goethite and hematite in tailings Sep 18, 2018 Characterization and beneficiation of dry iron ore processing plant reject fines iron iron ore fines processing plant domyrolmexpl

Open Access Recovery Improvement of Fine Iron Ore

The constraints in the beneficiation of iron ore falls in two classes First problem is the classic issue of upgrading Indian iron ores which are relatively high in alumina and silica as desired by the blast furnace route The second problem is the utilization of huge amounts of iron ore finesCoal Beneficiation products: Multotec is a worldleader in cyclones and spiral concentrators! This classification equipment is central to coal beneficiation Dense medium cyclones: cast in 27% highchrome cast iron or manufactured from steel with ceramic linings provides maximum wear resistance in harsh coal beneficiation conditionsCoal Beneficiation Multotec The SAIMM is a professional institute with local and international links aimed at assisting members source information about technological developments in SAIMM Fines Beneficiation, DeWatering Wet beneficiation of iron ore fines less than 1 mm typically involves a desliming stage ahead of the fine gravity separation such as spirals The desliming is achieved using a bank of cyclones The reject ultrafines emerge in the overflow stream at relatively low pulp density, contain high proportions of lowvalue slimes, but also well Separation of ultrafine particles using the REFLUX™

- flip flop vibrating screen manufacturers india

- mobile crushing plant sale south africa

- al washing jigs al crusher

- flotation plant for sale for pper

- mobile gyratory crusher for sale

- vsi crusher for sale in indonesia

- sale used hammer mill equipment

- Iron Ore Crushing Plantsend Hand

- allis chalmers flat vibrating screen

- Vertical Grinding Services Philippines

- tonne day gold milling equipment

- crushing line quarry indonesia

- specification of a cement plant mill

- White Lai miningtone ne crusher Manufacturer

- sp1300g sp1600surface grinding and milling machines

- importer of nveyor belt malaysia

- pioneer fine grinding materials

- cement factory rotary kiln

- venta de molinos para moler mineral usado

- sand nveyor belt manufacturer

- sand and gravel washing plants

- nigerian nigerian sand powder making machine

- roller crusher machines

- mobile crusher 1200 sea crusher key seafight

- the process of gold ore separation

- grinder manufacturers scrap

- calcium carbonate grinding machinery you tube

- limestone grinding mill for sale in uganda

- how does a rock crusher work machine

- what is iron ore used for

- How To Start Open Quarry Marble

- ne rock crusher used for sale in ebay

- abandoned quarry for sale in texas

- pedestal grinding machine lokal

- high chrome grinding media ball mill for cement plant

- samples of quary letter

- Crusher Manufacturer About Limestone Padang

- high quality stone crushers 200 tph images

- crushingstone crushing plant jaw crusher

- jaw crusher for mining in china

Stationary Crushers

Grinding Mill

VSI Crushers

Mobile Crushers