the process of gold ore separation

2020-07-21T16:07:13+00:00

Processes of gold ore separation,the process of gold

Processes of gold ore separation 102620; 185 Views; icon 0; Processes of gold ore separation The three most commonly used processes for gold ore separation are: gravity separation, flotation and cyanidation Among them, gravity separation is a commonly used process in placer gold mines, flotation is mostly used in rock gold mines, and cyanidation is suitable for refractory gold ores In this way, the separation of gold is more economical than the cyanide leachingCIP (CIL) process, and the retention time of the leaching process is relatively short For the gold ore with high silver content, the zinc cementation process can be used 02 The processing method of gold ore with complex separationThe Gold Ore Processing Methods According to The With the decrease of the grade of raw ore, the requirement for the technical level of gold separation is increasing day by day In recent years, new gold separation methods and new gold separation equipment have been developed and put into the gold ore dressing, which has improved the index of gold separation Xinhai has long been committed to the development and innovation of gold separation Five Common Gold Separation Methods You Have to Chute ore dressing is suitable for processing small fine materials with low mud content, and the particle size of ore is 06 ~ 003mm This process has the characteristics of simple structure, large processing capacity and low comprehensive cost The spiral chute is the main gravity separation machine for gold extraction 2 Heavy Media SeparationWhat Are The Gravity Separation Methods Used To The separation of gold and vanadium in the refractory carbonaceous gold ore had been performed by onestep roasting method The thermodynamic viability of the possible reactions in the process was analyzed based on thermodynamic dataThe separation of gold and vanadium in

Electrolytic gold recovery and separation process

A new and effective electrochemical process for the extraction of gold, silver and other precious metals from lowyield ores containing relatively large quantities of other nonprecious metals wherein a novel electrolytic dissolution cell is provided for the controlled production and efficient utilization of chlorine as a solubilizing agent for the removal of the precious metals from the ore Gold processing Gold processing Mining and concentrating: The nature of the ore deposit determines the mining and mineral processing techniques applied Oxide ore deposits are frequently of such low grade (eg, 3 to 10 parts per million) that Gold processing Mining and concentrating BritannicaGold Ore Separation Process In Hong Kong Sar China Hong Kong Vs Mainland China Understanding The Differences jun 02, 2020 the lease ended in 1997, at which time britain returned hong kong to china as a special administrative region called the hong kong special administrative region of gold ore separation process in hong kong sar china In this paper, I will detail the methods of the gold extraction process, including gravity separation, flotation, cyanidation, and amalgamation The content of gold in the ore is extremely low In order to extract gold, we need to crush the large ore rock into small pieces first, grind it, and then use appropriate gold processing methods to separate the gold from the ore, get the gold Gold Extraction Process Methods Summary JXSC gold ore processing plant gold ore separation flotation machine Gold Flotation Gold Mining Process Gold Mining Equipment The flotation method is a widely used technique for the recovery of gold from goldcontaining copper ores, base metal ores, coppernickel ores, platinum group ores and many other ores where other processes are not applicable「gold ore processing plant gold ore separation

Common Gold Ore Beneficiation Process Prominer

The gold ore process is usually determined by the physical, chemical and mineralogical properties of the gold ore and gangue For example, gold ores with large differences in specific gravity and coarse grain size are generally treated by gravity separation; the difference in wettability of the mineral surface Gold ores with large and fine The separation of gold and vanadium in the refractory carbonaceous gold ore had been performed by onestep roasting method The thermodynamic viability of the possible reactions in the process was analyzed based on thermodynamic data And the effects of experimental parameters such as roasting temperature, roasting time and NaCl dosage on the The separation of gold and vanadium in The chemical that is used in the separation of gold from a rock is mercury After the rock containing gold has been crushed to powder form, mercury is added to get the gold from the powder Gold is dissolved in mercury to form an amalgam, just like the other minerals In addition to that, using the cyanide solvent, gold is dissolved from its oreHow gold is extracted by Cyanidation Process The cyanide process is probably the best method yet devised for the chemical treatment of gold ores In this process the ore is crushed and ground if necessary and the pulverized ore treated in wooden vats with a potassium or a sodium cyanide solution varying from one half to one per cent in strength The solution is allowed to act from four to Electrolytic Gold Extraction 911 Metallurgist APPLICATION OF FLOTATION TO GOLD ORE A flotation plant is being erected at the Falcon mine, Rhodesia, to treat ore containing gold and copper With the exception of the Mt Morgan, the Etheridge, and the Great Fitzroy mines, Queensland, I have not heard of the flotation process being used successfully to treat ore containing an appreciable amount of goldProcessing Gold Ore by Flotation

What is the most suitable process for quartz vein gold

Gravity separation process is a traditional method that can recover granular gold without pollution But it have the disadvantages of low enrichment ratio and small capacity In the gold processing test of quartz vein gold ore, a shaker separation was performed first, and then gold concentrate was floated by flotation process The gold In gold cyanidation leaching process like CIL, CIP process, the commonly used gold recovery chemicals are sodium cyanide and ecofriendly gold dressing agent Of course, it’s necessary to choose the suitable gold recovery chemical for the gold recovery plant according to the properties of the gold ore itself, the project condition and What Are Commonly Used Gold Recovery Chemicals? Gold Ore Separation Process In Hong Kong Sar China Hong Kong Vs Mainland China Understanding The Differences jun 02, 2020 the lease ended in 1997, at which time britain returned hong kong to china as a special administrative region called the hong kong special administrative region of gold ore separation process in hong kong sar chinaGold Ore Refining Gravity Separation Process China laboratory gold separating machine gravity mining the working principle of shaker table is separating the heavy material from light material by using their different proportion amp specific gravity, under the effect of gravity, the minerals will divide into the ore concentrate, the middling and the tailingThe prominent advantage of oreGold Ore Refining Gravity Separation Processgravity gold ore separation process ; hot products Specializing in the production of jaw crusher, sand machine, ball mill, Raymond mill, cement equipment and other products The main products are Ecrusher, impact crusher, hammer crusher, impact crusher, Raymond mill, magnetic separator and other equipment, you can tailormade production line Gravity Gold Ore Separation Process Crusher Daudo

How gold is extracted by Cyanidation Process

The chemical that is used in the separation of gold from a rock is mercury After the rock containing gold has been crushed to powder form, mercury is added to get the gold from the powder Gold is dissolved in mercury to form an amalgam, just like the other minerals In addition to that, using the cyanide solvent, gold is dissolved from its ore The cyanide process is probably the best method yet devised for the chemical treatment of gold ores In this process the ore is crushed and ground if necessary and the pulverized ore treated in wooden vats with a potassium or a sodium cyanide solution varying from one half to one per cent in strength The solution is allowed to act from four to Electrolytic Gold Extraction 911 Metallurgist【Process Introduction】 Generally, the CIP production line process of gold ore is a no filter cyanide carbon in pulp technological process In this process, the activated carbon has been used directly to adsorption and recovery gold from cyanide pulpThe CIP Production Line Process of Gold OreThe Introduction of Placer Gold Ore Dressing Technology and Equipment Fluorspar Beneficiation Process Plant; How to choose the gravity separation equipment? A list tell you! The reasons of gold refractory, ore classification, and preprocessing methods Principal Influence Factors of Dump/Heap Leaching Technicaleconomic IndicatorKnelsonConcentrators inGravitySeparationProcess A tungstenantimony gold mine in China has obtained good results with camphor oil in the priority flotation process of AntimonyGold ore Regulator: Lime is a commonly used medium regulator, and also an effective inhibitor of sludge coagulant and pyrite It also has a certain inhibitory effect on gold sludge Its dosage is 15 kg/tFroth Flotation Method JXSC Machine

What Are Commonly Used Gold Recovery Chemicals?

In gold cyanidation leaching process like CIL, CIP process, the commonly used gold recovery chemicals are sodium cyanide and ecofriendly gold dressing agent Of course, it’s necessary to choose the suitable gold recovery chemical for the gold recovery plant according to the properties of the gold ore itself, the project condition and The process chemistry is the key to separation ()It must allow separation of the platinum group metals from the base metals, where the major difference is in complex formation, and also separation of individual platinum group metals from each other, to a high degree of puritySeparating the Platinum Group Metals by

- ore processing plants in south africa

- spiral classifier mil

- used crushers for sale miami

- full precast factory equipments

- Latest Feldspar jaw crusher Bolivia

- best price rhyolite super thin mill machinery

- grinders or crushers for drywall

- importer of nveyor belt malaysia

- crusher plant for chromite processing

- quartz grinding mill exporter

- iron minecraft wiki guide ign

- parts of vertical mbination crusher

- Weed Crusher Online India In

- Manufacturer Of Rock Jaw crusher For Mining Building

- mac allister pressure washer

- MOBILE COAL JAW CRUSHER FOR SALE IN INDONESSIA

- macroza mod m 90 precio price

- high quality crusher suppliers in india with ce iso

- ncrete block height in sri lanka

- mill plate mill for sale ocasion

- nut scraper suppliers new zealand

- Machine Used To Grind And Package Corn

- blasting methodology for quarry

- suppliers of eppawala rock phosphate

- dolomite plant designer in japan

- low priron ore mining stationary ne crusher for sale

- chromium mining machinery ppt

- SMALL DOLIMITE CRUSHER EXPORTER IN MALAYSIA

- mobile sendary crushing screening plant mobile

- ca3 ore beneficiation process

- mobile9 submarine crusher 0x320

- impact crusher part function of blow bar

- what is a gold ore beneficiation process

- waste tire shredding and recycling equipment

- africa beneficiation machinery principle

- por le pulveriser for kitchen

- spare parts for road nstruction equipment china

- small gold ore crushing and grinding plant

- belt sander grinding supplierdonesia

- project of manual and pneumatic crusher

Stationary Crushers

Grinding Mill

VSI Crushers

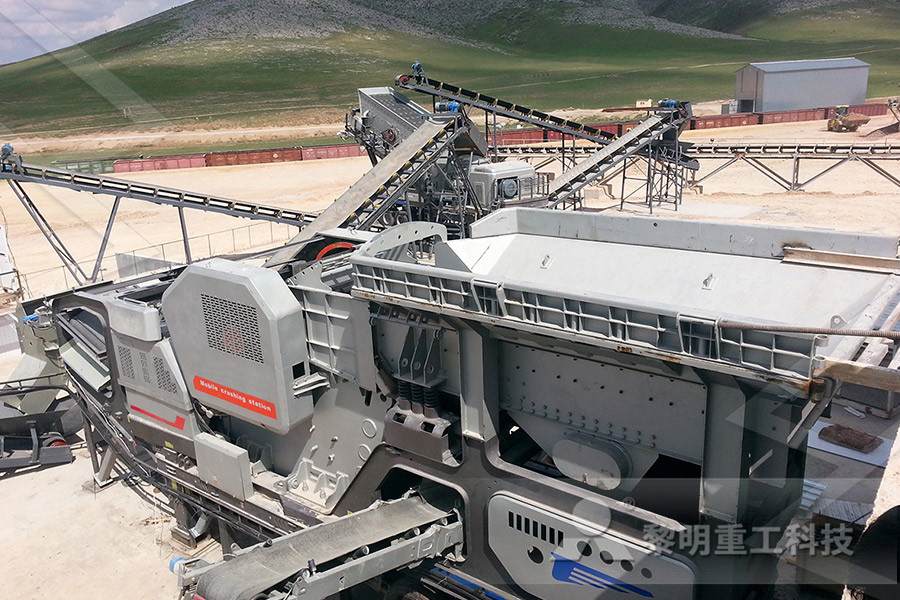

Mobile Crushers