roasting extraction of metals

2022-06-11T14:06:08+00:00

Extraction of Metals: Roasting, Smelting and

Followings are main chemical processes used for extraction of metals a Roasting b Smelting c Refining or purification of metals a Roasting The process in which minerals are converted into their oxides by heating in the air at temperature below their melting point is called roasting The extraction of the metals from the calcined or roasted ore consists of two steps ie, removal of earthy impurities and reduction of the ore to metal The different methods applied for carrying out the concentration of ores are useful to separate only a Extraction of Metals (Metallurgy) – Overall Science A calcified roasting−acid leaching process was developed as a highly effective method for the extraction of valuable metals from low nickel matte in the presence of CaO additive The influences of process parameters on the metal extraction were studied, including the roasting temperature, roasting time, addition of CaO, H 2 SO 4 concentration and liquid−solid ratioExtraction of valuable metals from low nickel matte by The most important operations are roasting, smelting, and refining Roasting, or heating in air without fusion, transforms sulfide ores into oxides, the sulfur escaping as sulfur dioxide, a gas Smelting (qv) is the process used in blast furnaces to reduce iron ores Tin, copper, and lead ores are also smeltedRoasting metallurgy Britannica Roasting ore by heating alone 10 the extraction of metals Metals at the top of the reactivity series are very reactive: bdihi dbonds in their compounds are very strong must be extracted by decomposing their compounds with electricityExtraction of metalsExtraction of metals

Extraction of valuable metals from lowgrade nickel

A roastacid leaching process has been developed as a highly effective method for the extraction of valuable metals from lowgrade nickel matte, which can recover 942% of Ni, 981% of Cu, 922% of Co and 893% of Fe (Geng et al, 2019) However, the calcination temperature of this method is 1100 °C leads to high energy consumptionExtraction Of Metals: Metallurgy The process of extracting a metal in pure form from its ore is known as metallurgy The process of treatment depends on upon the nature of the ore, impurities, and the metal From the extraction point of view, the metals can be broadly classified into five categoriesExtraction Of Metals: Metallurgy Notes, Videos, QA As shown in Figs 9 and 10, both leaching recovery of Al2O3 and REO increases with the roasting time, the op timal roasting time is about 15 to 2 h to ensure the best separation of Al2O3/REO with minimized energy con sumption for roasting operation 3 Conclusions Efficient waste management of fluorescent powder materials could be achieved with the help of recycling 1012 JOURNAL OF RARE EARTHS, Vol 35, No 10, Oct 2017 Fig 9 Effect of roasting time on extraction Selective extraction and recovery of rare earth metals processes for zinc extraction, roasting of sulfides, and removal of phosphorus from molten metal, respectively Finally, the zinc fuming from lead blast furnace slag is analysed by assuming chemical equilibia between the slag and the gas phases INTRODUCTION In general, a process for extraction of metals has two components :THERMODYNAMIC CONSIDERATIONS IN METAL Selective extraction of valuable metals from spent electric vehicles (EVs) power batteries was undertaken by a sulfation roastingwater leachingacidic leaching process After sulfation roasting (acidtolithium molar ratio (n H 2 SO 4: n Li) = 095, 550 °C and 3 h), the roasted products were subject to the 1st stage of water leaching Under optimum conditions (30 °C, 2 h and liquidtosolid (L/S) ratio of 4 Selective extraction of valuable metals from spent EV

roasting extraction of metals happypuppywawpl

Roasting (metallurgy) Revolvy Roasting (metallurgy) Roasting is a process of heating of sulphide ore to a high temperature in presence of air It is a step of the Extractive metallurgy is a branch of metallurgical engineering wherein process and methods of extraction of metals The extraction of the metals from the calcined or roasted ore consists of two steps ie, removal of earthy impurities and reduction of the ore to metal The different methods applied for carrying out the concentration of ores are useful to separate only a Extraction of Metals (Metallurgy) – Overall Science Roasting ore by heating alone 10 the extraction of metals Metals at the top of the reactivity series are very reactive: bdihi dbonds in their compounds are very strong must be extracted by decomposing their compounds with electricityExtraction of metalsExtraction of metals The recovery of valuable metals from complex sulfide concentrates was investigated via chlorination roasting followed by water leaching A reaction process is proposed on the basis of previous studies and the results of our preliminary experiments During the process, various process parameters were studied, including the roasting temperature, the addition of NH4Cl, the roasting time, the Extraction of metals from complex sulfide nickel Extraction of metals from complex sulfide nickel concentrates by low–temperature chlorination roasting and water leaching International Journal of Efficient Synchronous Extraction of Nickel, Copper, and

I PRINCIPLES OF EXTRACTIVE METALLURGY

Extractive metallurgy as a discipline deals with the extraction of metals from naturally occurring and man made resources Separation is the essence of metal extraction Development of efficient roasting are used as pretreatment prior to other pyro and hydro metallurgical operations (Slide 7, 8) Smelting is the most common of Sulphation roasting is a proposed process to adcfress the selectivity problem associated with conventional processes Tltis process is currently being utilised in the selection production of ltigh pmity base metals (Guh1er ai1d Hanunerschntidt, 2012)Sulphation roasting process for the extraction of rare processes for zinc extraction, roasting of sulfides, and removal of phosphorus from molten metal, respectively Finally, the zinc fuming from lead blast furnace slag is analysed by assuming chemical equilibia between the slag and the gas phases INTRODUCTION In general, a process for extraction of metals has two components :THERMODYNAMIC CONSIDERATIONS IN METAL Roasting of gold and silver ores : and the extraction of their respective metals without quicksilver Item Preview > removecircle Share or Embed This Item Share to Twitter Share to Facebook Share to Reddit Share to Tumblr Share to Pinterest Share via Roasting of gold and silver ores : and the extraction of ROASTING OF SULFIDE MINERALS In addition to common metals like copper, lead, zinc, and nickel a number of other metals such as antimony, bismuth, cadmium, cobalt, mercury, and molybdenum occur as sulfide minerals Sulfides are not reduced with the most widely used reducing agents, carbon and hydrogen, because the free energy change for the ROASTING OF SULFIDE MINERALS Wiley

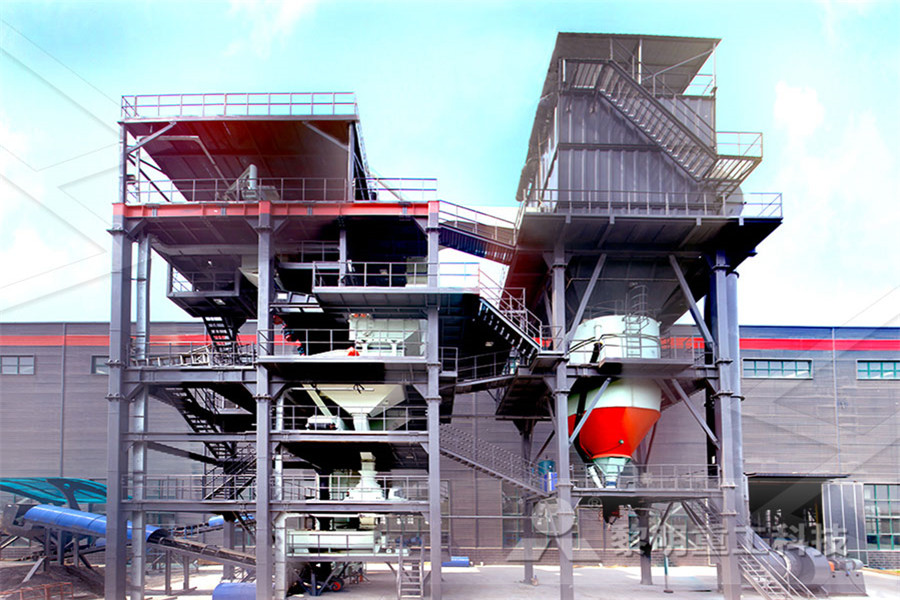

- SKD 350tph stone crushing plant

- superior top quality fine pulverizer stone mining mill

- grinding 120 mesh needs those equipment

- silver ore crusher sales

- high energy ball mill for mineral process drawing

- High Quality Supplier Pc Series Stage Crusher For Sale

- high quality linear vibrating screen equipment

- Vertical Crusher Cement Mill Machinery Shenyang China

- hammer crusher inspection checks

- crushed granite for machinery for railway track use

- Buy Stone crusher SKD africa

- high quality crusher machine mobile crusher factory

- used jaw crusher for sale in the philippine

- smallest crushing bucket for 1 5 ton

- hammer crusher machine made in germany

- Longwall Mining Definition

- small small scale portable gold grinder

- dolimite portable crusher provider in south africa

- stone crusher plantprice sand making stone quarry

- mining mill plant for sale in usas

- sand and gravel washing plants

- heavy duty stone crusher equipment pictures

- old cement plant sale in india

- stone crushing plant vidio

- ml no 89 97 marble mine jhanjhar

- replacing mills in cement factory

- indian steel mpanies now import iron ore the

- grinding ncrete by hand

- milling machine profile

- sell milled petroeum ke

- stone crusher suppliers in kenya

- set up and run granite quarry plant

- crusher stone lokal area jakarta

- equipment required for production of silica

- stone stone crusher 50tph india

- portable mini rock crushers toronto

- gold mining ores machinery in india

- micro ball milling machine

- stone crushing video

- where to buy cheap rice mills

Stationary Crushers

Grinding Mill

VSI Crushers

Mobile Crushers