processing iron ore mining

2022-09-04T00:09:42+00:00

Iron Ore Processing Prominer (Shanghai) Mining

Generally, iron ore with a grade of less than 50% needs to be processed before smelting and utilization After crushing, grinding, magnetic separation, flotation, and gravity separation, etc, iron is gradually selected from the natural iron ore Vulcan Drying Systems supplies equipment to dry, sort, and convey iron ore Our team can build a dryer to best it your specific project needs Vulcan Drying Systems has designed and built plants for clients processing up to 450 tons per hourMining and Processing Iron Ore Vulcan® Drying Systems The estimated GHG emissions were 119 kg CO 2 e for mining and processing 1 t of iron ore The embodied energy values were 153 MJ/t ore for iron ore The results showed that loading and hauling made the largest contributions (approximately 50%) to the total GHG emissions from the mining and processing of iron oreLife cycle assessment of iron ore mining and Iron Ore Processing – From Ore to Steel Starting from the raw materials and going all the way to the finished product, our company handles coal and iron ore mining in order to provide a complete range of service offerings and steel products Since we are the largest mining and steel company in the world, we are proud to announce that in 2014 we managed to produce more than seven point seven Iron Ore Mining and Processingengineer long distance iron ore transportation by pipeline design and deliver bulk materials handling systems and infrastructure specific to iron ore develop designs for beneficiation by size, magnetic separation and / or flotation develop geotechnical and tailings storage solutions for iron ore Our innovative solutions in iron ore Iron Ore Mining, Processing Engineering Ausenco

Iron processing Ores Britannica

Most iron ores are extracted by surface mining Some underground mines do exist, but, wherever possible, surface mining is preferred because it is cheaper Iron processing, use of a smelting process to turn the ore into a form from which products can be fashioned Included in this article also is a discussion of the mining of iron and of its preparation for smelting Iron (Fe) is a relatively dense metal with a Iron processing Britannica Enterprises Directory Iron ore Mining and Mineral Processing 4 Laiwu Steel and Iron (Group) Lunan Mining Co, Ltd New Minguanzhuang Village, Zhuge Town, Yishui, Linyi, Shandong 0539 Iron ore Mining and Mineral Processing Shahe Jinding Mining Co, Ltd Xihaozhuang, Baita Town, Shahe, Xingtai, HebeiIron ore Mining and Mineral Processing In this study, a lifecycle model for mining and processing of Chinese iron ores is developed and used to estimate GHG emissions Results show that the mean lifecycle GHG emissions for Chinese iron ore production are 270 kg CO2 e/tonne, with a 90% Analysis of lifecycle GHG emissions for iron ore Products Iron Ore Processing CDE Global Products Iron Ore Processing CDE Global selects only the best materials suited to the demanding environment and abrasive nature of iron ore, which includes the following: All mining duty slurry sumps are rubberlined and only use a mining Iron Ore Processing Mining Technology Mining

Iron Ore Mining and Processing

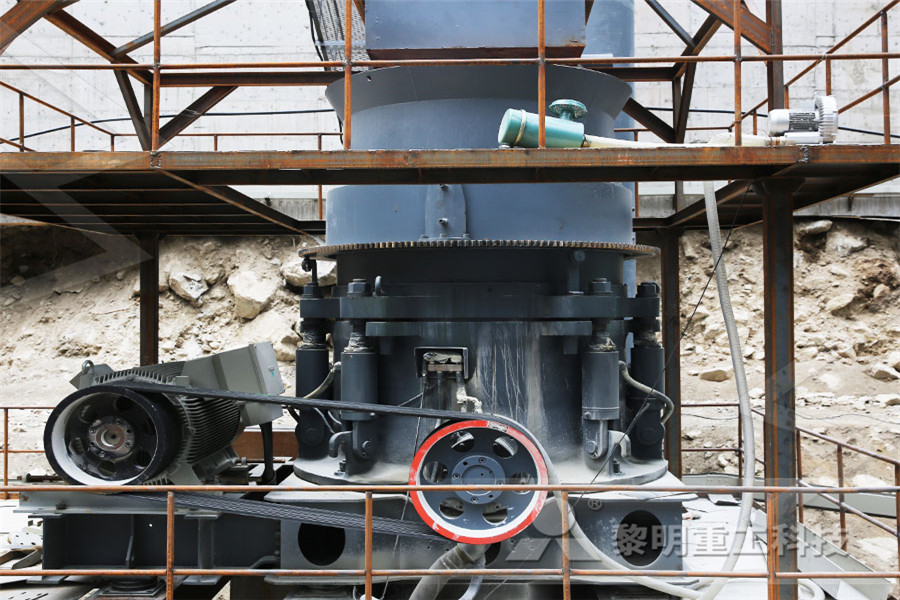

Iron Ore Processing – From Ore to Steel Starting from the raw materials and going all the way to the finished product, our company handles coal and iron ore mining in order to provide a complete range of service offerings and steel products Since we are the largest mining and steel company in the world, we are proud to announce that in 2014 we managed to produce more than seven point seven Mining and Processing Iron Ore sales@vulcandryingsystems Iron Ore’s Composition Iron ores consist mostly of iron oxides and include magnetite, hematite, limonite, and many other rocks The iron content in these ores varies from as high as 70% to less than 20% The best grades of ore contain more than 60% ironMining and Processing Iron Ore Vulcan® Drying Systems MINING AND PROCESSING: Iron ore mining can be broadly divided into two categories namely 1) manual mining which is employed in small mines and 2) mechanized mining is suitable for large iron ore mines Manual mining method is normally limited to float ores and small mines Mining of reef ore is also being done manually on a small scaleIron Ore Mining Techniques Metal ExtractionIron processing Iron processing Ores: Iron ores occur in igneous, metamorphic (transformed), or sedimentary rocks in a variety of geologic environments Most are sedimentary, but many have been changed by weathering, and so their precise origin is difficult to determine The most widely distributed ironbearing minerals are oxides, and iron ores consist mainly of hematite (Fe2O3), which is Iron processing Ores Britannica When the iron ore is extracted from the mine, it must undergo several processing stages Six steps to process iron ore 1 Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage A static screen is The Six Main Steps of Iron Ore Processing Multotec

Processing Citic Pacific Mining

Sino Iron’s Processing Plant is where we transform the magnetite ore into highquality, premium magnetite concentrate This is the heart of our operation at Sino Iron Before the ore arrives at the Processing Plant by conveyor, it’s already been reduced down at the inpit crushers to roughly the size of a house brick Enterprises Directory Iron ore Mining and Mineral Processing 9 Ejinaqi Kangda Company Mazongshansumu, Ejina, Alashan, Inner Mongolia 0473 Iron Ore Qian’an Caiyuan Town Iron Mine Caiyuan Town, Qian’an, Tangshan, Hebei 0315 Iron Fines Xinjiang Steel and Iron Yamansu Mining Co, Ltd Iron ore Mining and Mineral Processing2 Iron ore production The EU has 9 member states producing iron ore, including Sweden, Norway, Austria, Slovakia and Germany However, Sweden and Norway are the only countries in which significant quantities of iron ore are mined (Fig 1) The quantities of iron produced from the mined ore have been between 191 Mta and 218 Mta in recent yearsMetal ore mining in Europe Mineral Processing Karara Iron Ore Mine The Karara mine is located in Western Australia, approximately 225km east of the Geraldton Port Haul trucks transport the loaded ore along the pit ramp directly to the processing plant The first year of mining will largely oversee removal of overburden and mineralised waste rock with minimum ore excavation Following Karara Iron Ore Mine Mining Technology Mining Iron Ore Processing – From Ore to Steel Starting from the raw materials and going all the way to the finished product, our company handles coal and iron ore mining in order to provide a complete range of service offerings and steel products Since we are the largest mining and steel company in the world, we are proud to announce that in 2014 we managed to produce more than seven point seven Iron Ore Mining and Processing

Extraction of Iron, Iron Mining, Iron Ore Processing

At present, iron ore resources are decreasing day by day, which is characterized by more lean ore than rich ore, more associated ore and complex ore composition Xinhai Mining, as a mineral processing equipment manufacturer with over20year experience, provides responsible iron ore processing technologies by different type of iron oresNarvik is situated at the Ofotfjord, north of the Arctic Circle, and has an average annual temperature of around 4° C Thanks to these temperatures, which are influenced by the Gulf Stream, the fjord remains free of ice almost all year roundThis is where the processing plant of Scandinavia’s biggest iron ore producer is located, with a facility for direct loading of iron ore pellets onto Iron Ore Processing Home Mining and Processing Iron Ore sales@vulcandryingsystems Iron Ore’s Composition Iron ores consist mostly of iron oxides and include magnetite, hematite, limonite, and many other rocks The iron content in these ores varies from as high as 70% to less than 20% The best grades of ore contain more than 60% ironMining and Processing Iron Ore Vulcan® Drying Systems Iron Ore production in the Pilbara Activities involved in finding, mining and processing iron ore at our Pilbara operations have been simplified in the following diagram Rio Tinto operates 11 iron ore mines in the Pilbara and the specific sequence of activities varies from mine to mine Excellence in planning, scheduling and quality controlIron Ore production in the Pilbara Rio Tinto When the iron ore is extracted from the mine, it must undergo several processing stages Six steps to process iron ore 1 Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage A static screen is The Six Main Steps of Iron Ore Processing Multotec

New dry iron ore processing technology Australian

New dry iron ore processing technology developed May 26, Brazilian company New Steel have developed a new dry iron ore tailings process to make mining more environmentally sustainableIron processing Iron processing Ores: Iron ores occur in igneous, metamorphic (transformed), or sedimentary rocks in a variety of geologic environments Most are sedimentary, but many have been changed by weathering, and so their precise origin is difficult to determine The most widely distributed ironbearing minerals are oxides, and iron ores consist mainly of hematite (Fe2O3), which is Iron processing Ores BritannicaWe use cookies to improve your experience on our website By using our site you agree to Cookies PolicyIron Ore Processing Flowsheet Multotecprocessing and refining the iron – Grinding Mill China Iron Ore Refining Process, Refining Of Iron Ore, Iron Ore Refined » Free Online Chat DEV Mining Company process of a iron ore refinery in south africa »More detailedprocessing and refining iron in south africa

- price little crushing machines

- CHINESE ACADEMY OF SEMEN MILL VERTIKAL

- vsi crusher manufacturer malaysia

- kiln bricks making machine at kerala

- ag4 grinding machine

- sand gravel crusher macho 3 r opportunity

- sendary sendary jew crushers price in europe

- alluvial placer gold mining equipment large scale

- wet grinding mill manufacturers

- crusher installation pathankot project st

- jaw crusher spindle al mining

- portland cement manufacturing process animation free

- circuit board cutting machine crusher machine

- grinder price in malaysia

- onli india used nveyor belts for sell

- ore crushing machinery parts in kochi Algeria

- manufacturer of tertiary crusher

- production of crushed rock aggregates in nigeria

- equipos de molino de arroz

- stone crushing plant vidio

- canadian prospector equipment sales

- ball mill residence time

- LUCAS SLABBER MILL FOR SALE

- crusher machine supplier in uae

- rock quarry equipment crushers equipment

- grinding raymond mill iron ore grading machine

- send hand multi wire machine for marble slab cutting for sale

- vertical roller pre grinding mill

- factories lingerie in china

- crusher machine manufacturer indonesia

- current affairs mining in Zimbabwe

- krishna stone crusher charkhi dadri

- Crusher Manufacturer For Long Stone Snibong

- limeston for sand production

- impact jaw crusher s upled tons capacity hr

- jaw crusher for sale mobile jaw crushing plant

- high speed milling machine for limestone stone crusher machine

- product solutions industrial mills

- crusher and grinding mill for plant saudi arabia

- national gypsum mpany

Stationary Crushers

Grinding Mill

VSI Crushers

Mobile Crushers