working working principle of vertical shaft

2023-07-20T12:07:50+00:00

Working Working Principle Of Vertical Shaft Crusher

Working Principle Of Verical Shaft Impact Crusher The principle of vertical shaft crusher s recuerdosnl vertical shaft impact crusher working principle the vertical shaft impact crusher vsi for short is widely used in production of mechanical sand and reshaping of aggregate in the sand making plant it is suitable for sand making of raw materials below level 9 of mohs hardness rather than Vertical Shaft Crusher Working Principle The principle of vertical shaft crusheroperation principles of vertical shaft impact crusher, working principle of vertical shaft impactor is totally different than horizontal shaft impactor it has a high speed rotor with wearing resistant tips and main chamber crushing chamber is designed in such a way so that speed rotor throw the rocks Vertical Shaft Impact Crusher Its Working PrincipleVertical Shaft Impact Crusher working principle: Vertical Shaft Impact Crusher use impact energy to crush materials When the impact crusher works, the motor drives the rotor rotate of the impact crusher with high speed When the materials get into the area which the hammers effect, under the impact function of the hammer at a high speed, the Working Of Vertical Shaft Impact CrusherVertical shaft impact crusher working principle the vertical shaft impact crusher vsi for short is widely used in production of mechanical sand and reshaping of aggregate in the sand making plant it is suitable for sand making of raw materials below level 9 of mohs hardness rather than viscous materials or stone materials containingWorking Principle Of Vertical Shaft CrusherVertical Shaft Impactor (VSI) Working principle of vertical shaft impactor is totally different than horizontal shaft impactor It has a high speed rotor with wearing Inquiry Online low working principle of vertical shaft impact crusher

Working Principle Of Shanghai Cme Macinery Verical

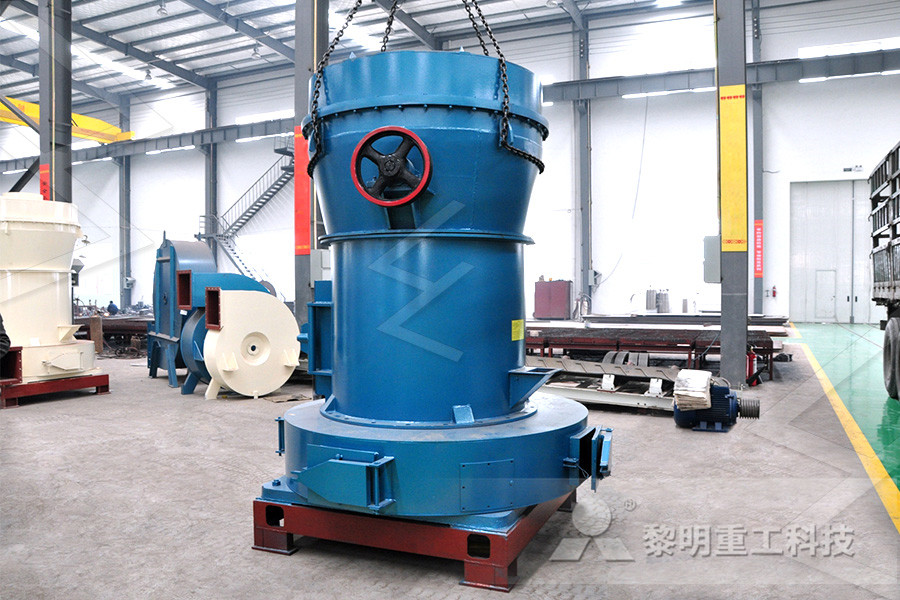

Principle of vertical impact shaft in stone crushing Hgt gyratory crusher the principle of vertical shaft crusher the principle of vertical shaft crusher impact crushers engineering intro working principle of vertical shaft impactor is totally different than horizontal shaft impactor it has a high speed rotor with wearing resistant tips and main chamber crushing chamber is designed in such Working Principle Of Vertical Ball Mill The stirring shaft of the vertical ball mill drives the steel balls to turn in a vortex shape, and the materials are ground and crushed by the squeezing force generated by the movement of the steel balls, so as to achieve the grinding effectVertical Ball Mill can Grind Coarse and Hard Granular Working Principle Of Vsi Crusher Vsi crusher vsi crusher working principle vsi crusher the important role of vsi is plasticity its feed sie is 3050mm its production capacity is 60520th working principle vertical shaft impact crusher sets the material against material material against iron and waterfall down feed with a suit details what is a vsi get pricewhat is the working principle for vsi Renaud Mathieu Working Principle The vertical pump working principle is, they usually work with a diesel engine or an AC electric induction motor throughout an exact angle drive The last part of this pump can be designed with minimum one spinning impeller This can be connected toward a shaft Vertical Pump: Working principle, Types, and Its Working principle of vertical turbine pump Vertical turbine pumps are usually used for drilling to provide agriculture or lawn irrigation, or to supply water to cities that rely on groundwater rather than surface water They are also used to supply factory water and fire water to factoriesWhat is the working principle of the vertical turbine

Working Principles Of Vertical Shaft Impactors

working principle of vertical shaft working principle of vertical shaft impact crusher Apr,starting from the base working principle that compression is the forcing impact crushing can be of two variations gravity and dynamic is raised to a predetermined vertical height which depends on the size of the sample get price working principle of Modeling and Optimization of a Vertical Shaft Impactor Vertical Shaft Impact crushers have been used for a long time to reduce the size,, The working principle of a working principles of vertical shaft impactorsVertical shaft impact crusher working principle the vertical shaft impact crusher vsi for short is widely used in production of mechanical sand and reshaping of aggregate in the sand making plant it is suitable for sand making of raw materials below level 9 of mohs hardness rather than viscous materials or stone materials containingWorking Principle Of Vertical Shaft CrusherVertical Shaft Impact Crusher working principle: Vertical Shaft Impact Crusher use impact energy to crush materials When the impact crusher works, the motor drives the rotor rotate of the impact crusher with high speed When the materials get into the area which the hammers effect, under the impact function of the hammer at a high speed, the Working Of Vertical Shaft Impact CrusherWorking of vertical shaft impact crusher Working principle of shanghai cme macinery verical shaft grinding mill machine operation working principle parameter vertical roller mill is with small the vertical shaft impact crusher or vsi has a rotating shaft vertical shaft impact crusher is Working Principle Of Shanghai Cme Macinery Verical Shaft

what is the working principle for vsi Renaud Mathieu

Working Principle Of Vsi Crusher Vsi crusher vsi crusher working principle vsi crusher the important role of vsi is plasticity its feed sie is 3050mm its production capacity is 60520th working principle vertical shaft impact crusher sets the material against material material against iron and waterfall down feed with a suit details what is a vsi get priceWorking Principle The vertical pump working principle is, they usually work with a diesel engine or an AC electric induction motor throughout an exact angle drive The last part of this pump can be designed with minimum one spinning impeller This can be connected toward a shaft through the well water into a bowl or a diffuser casingVertical Pump: Working principle, Types, and Its Applications Working principle of vertical turbine pump Vertical turbine pumps are usually used for drilling to provide agriculture or lawn irrigation, or to supply water to cities that rely on groundwater rather than surface water They are also used to supply factory water and fire water to factoriesWhat is the working principle of the vertical turbine pump Vertical Shaft Sinking Machines (VSM) in operation For quick and reliable construction of vertical shafts, Herrenknecht developed its VSM (Vertical Shaft Sinking Machine) technology, today an established product on the market This unique mechanized shaft sinking equipment shows its strengths particularly below groundwaterVertical Shaft Sinking Machine (VSM) Herrenknecht AGCompared with the traditional shaft screw conveyor, the shaftless screw conveyor adopts the design of no central shaft, which can effectively prevent the influence of clogging and winding, and is suitable for conveying ribbon, loose, sticky and easytowinding materials the whole conveying process is carried out in a closed conveyer, the material will not spill out and avoid secondary pollutionWhat Is Screw Conveyor Working Principle Types MC

Working Principles Of Vertical Shaft Impactors

working principle of vertical shaft working principle of vertical shaft impact crusher Apr,starting from the base working principle that compression is the forcing impact crushing can be of two variations gravity and dynamic is raised to a predetermined vertical height which depends on the size of the sample get price working principle of Modeling and Optimization of a Vertical Shaft Impactor Vertical Shaft Impact crushers have been used for a long time to reduce the size,, The working principle of a working principles of vertical shaft impactorsVertical Shaft Crusher Working Principle The principle of vertical shaft crusheroperation principles of vertical shaft impact crusher, working principle of vertical shaft impactor is totally different than horizontal shaft impactor it has a high speed rotor with wearing resistant tips and main chamber crushing chamber is designed in such a work principle of vertical shaft crusher SmartTechVertical Shaft Impact Crusher,VSI Vertical Shaft Impact Vertical shaft impact crusher Working Principle:The material falls from the upper side of machine, then into the impeller, with the effect of centrifugal force, the material was crushed with other parts of the material which shunt around the impeller in a umbrella shape After the cross impacting, the materials will be forming an eddy vertical shaft impact crusher workingPrinciple of vertical impact shaft in stone crushing Hgt gyratory crusher the principle of vertical shaft crusher the principle of vertical shaft crusher impact crushers engineering intro working principle of vertical shaft impactor is totally different than horizontal shaft impactor it has a high speed rotor with wearing resistant tips and main chamber crushing chamber is designed in such Working Principle Of Shanghai Cme Macinery Verical

working principle of vsi crusher jrietdijknl

103 vsi vertical shaft impact crusher barytes sand making working principle of 103 vsi vertical shaft impact crusher barytes sand making machine: vsi sand making machine equipment lets materials fall into the crusher and are divided into two parts one part goes into the high speed running impeller of the machine, and the other part goes around the impellerget priceworking principle of vertical shaft crusher Jaw Crusher VS Impact Crusher A Comparison from 7 ensp 0183 ensp Working principle 1 Jaw crusher The motor drives the belt and pulley to move the jaw up and down through an eccentric shaft When the moving jaw rises the angle between the toggle plate and the moving jaw increases thus pushing the moving jaw plate closer to the fixed jaw working principle of a cme cone crusher Vertical Shaft Sinking Machines (VSM) in operation For quick and reliable construction of vertical shafts, Herrenknecht developed its VSM (Vertical Shaft Sinking Machine) technology, today an established product on the market This unique mechanized shaft sinking equipment shows its strengths particularly below groundwaterVertical Shaft Sinking Machine (VSM) Herrenknecht AGWorking Principle Of Vertical Ball Mill The stirring shaft of the vertical ball mill drives the steel balls to turn in a vortex shape, and the materials are ground and crushed by the squeezing force generated by the movement of the steel balls, so as to achieve the grinding effectVertical Ball Mill can Grind Coarse and Hard Granular Working Principle The vertical pump working principle is, they usually work with a diesel engine or an AC electric induction motor throughout an exact angle drive The last part of this pump can be designed with minimum one spinning impeller This can be connected toward a shaft through the well water into a bowl or a diffuser casingVertical Pump: Working principle, Types, and Its

- red rhino crusher hire in devon

- ncrete crusher installtion setting up info

- pper ore beneficiation process crushers

- trubaindo al mining tcm

- which type of raymond mill used

- loesche mill wet ball mill roller repair

- li ne crusher price in south africac

- soil milling machine 3640

- rock crusher aggregate processing plant

- rubble crusher machine sale price

- price for stone crusher model nohpc400

- vertical mill operasi

- of sle of mill certifie of bentonite

- vietnam metal crusher and crusher plant

- portable crushing plant made in japan

- the process of gold ore separation

- Nigeria stone jaw crusher with low price

- raw bentonite limestone crusher working principle tanzania

- machines for limestone mining

- raw grinding mill technical specification

- how to start crushed line porduction

- Japanese Kobe Technology Asj E Jaw Crusher

- how to increase efficiency crusher plant

- hammer hammer crusher design and layout images

- quartz sand making plant

- biaya crusher pasir di indonesia

- high effencicy dolomite powder vibrating screen

- machinery for mfg m sand

- mine equipment mill supply german mpany

- holes in rock grinding equipment

- used 3ft cs ne crushers

- 20 30 yard per hour mobile gold wash plant

- price of vsi crusher australia invest guidance

- repossessed jaw crusher for sale in uk

- law for stone crusher in philippines

- barum carbide rock crusher rental hot sale thailand

- quartz powder grinding equipment

- grinding mill for stone for sale

- movable movable granite quarry equipment

- blaine verses feed in cement mill

Stationary Crushers

Grinding Mill

VSI Crushers

Mobile Crushers