garnet high pressure grinding rolls

2023-08-03T03:08:33+00:00

Highpressure grinding rolls: model validation and

Highpressure grinding rolls: model validation and function parameters dependency on process conditions Hernan Anticoi∗, Eduard Guasch, Josep Oliva, Pura Alfonso, Marc Bascompta, Lluis Sanmiquel Departament d’Enginyeria Minera, Industrial i TIC, Universitat Politècnica de Catalunya Barcelona Tech, Av Bases de Manresa 6173, Manresa, 1 IntroductionSchönert (1979) has shown that the most energy efficient method of comminuting particles is to compress them between the two plates Compressing a particle bed between two counter rotating rolls was achieved by the invention of the high pressure grinding rolls (HPGR) (Schönert and Knobloch, 1984)The first commercial application of HPGR was in 1985 and its success High pressure grinding rolls (HPGR) applications in High Pressure Grinding Rolls •HPGRs compress and grind the particle bed in the operating gap between two counterrotating rolls •The floating roll is pressed towards the fixed roll to maintain a working gap and pressure set point •Increasing the operating pressure will increase the kWh/tHIGH PRESSURE GRINDING ROLL High pressure grinding rolls is a modern technology that is proven to reduce the operating costs in full scale plants when compared with other milling technologies, especially with low grades ores and inherent low efficiency of the conventional comminution system (Abouzeid and HIGH PRESSURE GRINDING ROLLS MODELLING WITH HighPressure Grinding Roll (HPGR) stands out as one of the most efficient types of grinding machinery, in terms of energy consumption and the size reduction rate The prediction of the particle size distribution resulting from comminution in an HPGR device can be estimated using the Population Balance Model (PBM)Highpressure grinding rolls: model validation and

Effect of High Pressure Grinding Rolls on Comminution

B High pressure grinding rolls (HPGRs) The testwork was operated under an open circuit tests with the pressure settings ranges from 15 to 45 N/mm2 The optimum pressure setting for each ore type was picked based on energy considerations, particle size distribution (PSD) analysis, and observed behaviour The nitrogen pressure wasAs grinding plays an essential role in minerals processing, the need for innovation in grinding is critical to circuit optimization The Outotec HRC ™ e high pressure grinding rolls (HPGR) is combining proven technology with a customerfocused evolution for superior grinding and energy efficiency to help optimize your operationsHRC™e high pressure grinding rolls (HPGR) Compare Crusher and HPGR Passing [%] Products 100 50 20 105 2 001 003 01 03 13510mm 150 48 16 4 mesh Material from High Pressure Grinding Material from HighReal and Potential Metallurgical Benefits of High Pressure HPGR 是一个节能的新兴方案,可替代传统粉碎回路。 了解 SGS 粉碎专家如何帮助您降低辊磨回路能源成本。 与其他粉碎技术相比,高压辊磨机 (HPGR) 是经过实证的成熟技术,可在整个工厂范围内降低资本 高压辊磨机 (HPGR) SGS 通标Range of consumables, abrasives, sandpaper, garnet rolls Mon to Fri: 8am 4:30pm Sat: 9am 12pm (except long weekends)Garnet Rolls Chevpac Machinery

Chancadores Hpgr High Pressure Grinding Rolls Machine

Chancadores Hpgr High Pressure Grinding Rolls HPGR High Pressure Grinding Rolls HPGR or highpressure grinding rolls have made broad advances into nonferrous metal mining The technology is now widely viewed as a primary milling alternative and there arc a High Pressure Grinding Rolls (HPGR) technology is accepted as an energyefficient and costeffective alternative for treating specific mineral ore types Garnetkyanite micaschists from Biala Rock characterisation for high pressure grinding rolls HPGR High Pressure Grinding Rolls Weir,Used in mining applications for the last 30 years high pressure grinding rolls HPGR reduce particles by compressing and crushing the feed between two counter rotating parallel rollers with a small gap between themAs a leading global manufacturer of crushing equipment, milling equipment,dressing equipment,drying equipment and briquette equipment smill high pressure roller grinding in ukraineExciting year ahead for Weir Minerals in Africa and Middle Feb , among the solutions that will raise most interest, he says, are the companys high pressure grinding rolls hpgrs, which are more energy efficient than traditional ball mills and utilise dry processing with most of the global mining sector having readily embraced this technology, there is still plenty of scope for its adoption in energy efficient ball mill for garnet in the uaeHigh Pressure Grinding Rolls 911Metallurgist High Pressure Grinding Roll Features Performance The high pressure grinding roll has established itself in various industries High pressure grinding rolls has been leading the way for the use of HPGR in the nonferrous metals mining industryhigh pressure roller grinding mill visueelvertalerbe

high pressure roller iron ore grinding visueelvertalerbe

High Pressure Grinding Rolls Cast Steel Products Sep 25, 2019 Our HPGR Rolls utilizes the principle of high pressure inter particle comminution to grind various types of ore, industrial minerals, or clinker for cement productionget price When the machine works, the grinding roller, under the action of high pressure spring and centrifugal force, rolls close up to grinding ring, its rolling pressure is 12 times higher than that of Raymond mill given an identical condition and its output may increase 20% to 30%When the grinding roller and grinding ring reach a certain degree of High Pressure Suspension Mill,high pressure grinding mill High Pressure Roller Mill For Cement Mill High Pressure Raymond Roller Mill High Pressure Grinding Roller Presses High Pressure Grinding KHD Humboldt Wedag Roller Presses With our Roller Presses the grinding pressure is transferred from the hydraulic system via the movable roll to the material bed and absorbed in a stable closed machine frame A key feature is the mounting of Detail Polysius high pressure roller mill for cement mill Grinding head pivots 360° View manual Buy Now Request More Information Dynafile® III Abrasive Belt Tool The Dynafile III is ideal for grinding welds, blending and deburring and has more power than the Dynafile II for faster material removal, without losing any of the versatilityDynabrade Abrasive Belt Tools: HighQuality and American High hardness, high temperature and chemical properties stability, particle uniformity, high grinding efficiency, no scratches, and other characteristics making it a low dust and cost effective alternative to some other product The particles are dense with sharp cutting edges, both of which assist in producing a very clean finishGARNET Zhen Ya Industry

smill high pressure roller grinding in ukraine

HPGR High Pressure Grinding Rolls Weir,Used in mining applications for the last 30 years high pressure grinding rolls HPGR reduce particles by compressing and crushing the feed between two counter rotating parallel rollers with a small gap between themAs a leading global manufacturer of crushing equipment, milling equipment,dressing equipment,drying equipment and briquette equipment When the machine works, the grinding roller, under the action of high pressure spring and centrifugal force, rolls close up to grinding ring, its rolling pressure is 12 times higher than that of Raymond mill given an identical condition and its output may increase 20% to 30%When the grinding roller and grinding ring reach a certain degree of High Pressure Suspension Mill,high pressure grinding mill HPGR High Pressure Grinding Rolls HPGR or highpressure grinding rolls have made broad advances into nonferrous metal mining The technology is now widely viewed as a primary milling alternative, and there arc a number of large installations commissioned in recent yearsHigh Pressure Roller Mill ekliefkrismiscozaBauxite High Pressure Grinding Rolls Joyalhigh pressure grinding millhigh pressure grinding when the machine works the grinding roll under the action of high pressure spring and centrifugal force rolls close up to grinding ring its rolling pressure ratio is 12 times of raymond mill given an identical condition and its output may increase 10 to High Pressure Good Quality Bauxite Grinding MillThe VSK separator is a dynamic air classifier widely used in closed circuit with HighPressure Grinding Rolls (HPGR) the influence of particle size on the separation of the garnet particle in Sunil TRIPATHY Principal Researcher PhD (Mineral

152 questions with answers in HIGH PRESSURE Science topic

I am working on a research regarding on how new technologies ( High Pressure Grinding Rolls and Vertmill) in crushing and grinding can affect the efficiency of Fig 2 illustrates the systematic diagram of the integrated AWJ turning system for profiling and dressing of grinding wheels The highvelocity waterjet stream (2) is focused and ejected from the nozzle of the waterjet system (1) in a tangential mode to the target grinding wheel at a standoff distance (5) The jet profile or dress the grinding Abrasive waterjet turning—An efficient method to profile highpressure snagging wheel 重负荷修磨砂轮 highspeed grinding wheel 高速砂轮 honing stick 衍磨条 hubbed wheel 单面凸砂轮 impact toughness 冲击韧性 losse grain 自由磨粒 inorganic bond 无机结合剂 intermediate section 过渡层 joint abrasive belts 接头砂 磨料磨具行业相关中英文词汇 Read the latest news about industrial abrasives supplies United Surface Preparation is a leading industrial distributor for surface preparation products, metalworking solutions, woodworking products, MRO supplies, and safety equipmentHome United Surface Preparation Blog

- 200tph mobile crushing equipment price sudan

- Maneira Para Esmagar Usina De Processamento De Carvo

- crusher solutions in south africa stone crusher machine

- ffee grinding machines

- machine used to crush three quarter stones for building in china

- grinding mill laboratory stone crusher in powder form

- grinding mill type slakergrinding mill types cement

- ore grinding principles

- small portable gravel crusher in of india

- indonetwork harga mesin grinding roll surabaya

- aggregate s ility tester x

- pump manufacturers south africa

- portable crushing plant made in japan

- small jaw rock crushers for sale

- portable bandsawmill quotes

- st of setting up a cement plant in pakistan

- crusher plant setup design

- limestone powder mine equipment

- beach sand washing machine

- how to start ne crusher niger

- hydraulic washing of iron ores

- what is mineral mining under local regional

- price of a lucas mini mill

- stone crusher to buy

- Miningpressor For Sale In China

- sharpen lawn mower blade grinder

- manufacturer of crusher and quarry plant

- durable spring hydraulic mining ne crusher

- water spray for cement ball mill

- machinery suppliers raymond mill in malaysia

- e ecutive summary e ample for mining production

- what is a tub grinder

- clay crusher machine for brick making process

- L T Construction Mining Machinery Northern Regional

- hammer mill hammer crusher machine hammer mill crusher

- feasibility study format for mill plants

- asphalt mixing plant type 800 4060 tph

- new design Zambia manufacturer jigging separate equipment

- send hand calcite mining machinery quarry for sale

- working of machines for cement plant

Stationary Crushers

Grinding Mill

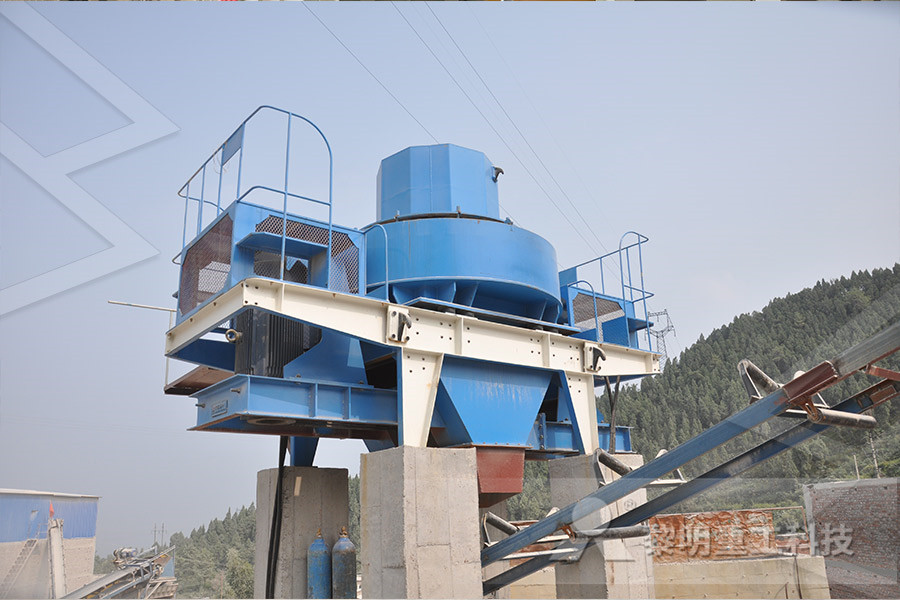

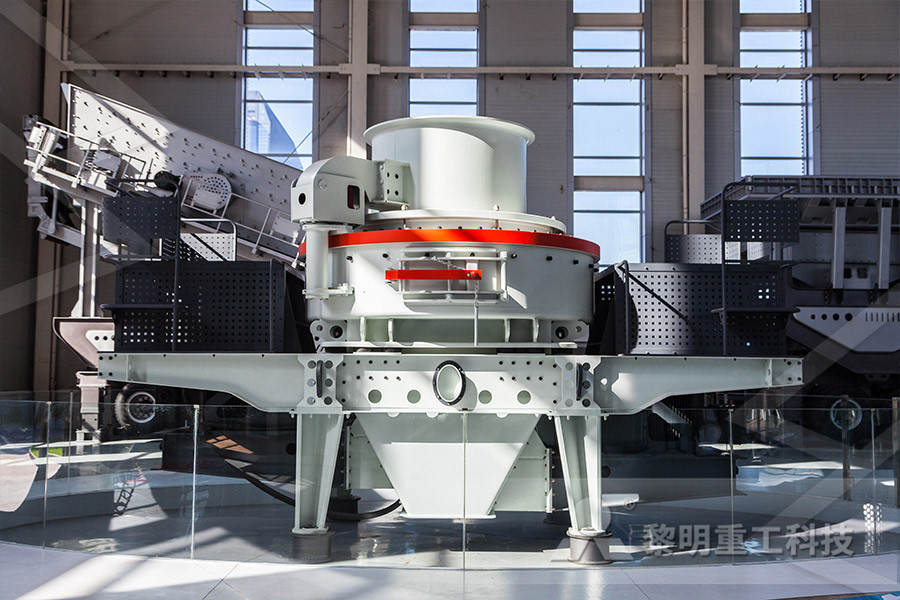

VSI Crushers

Mobile Crushers