what is done at a sand mine processing plant

2023-09-27T15:09:30+00:00

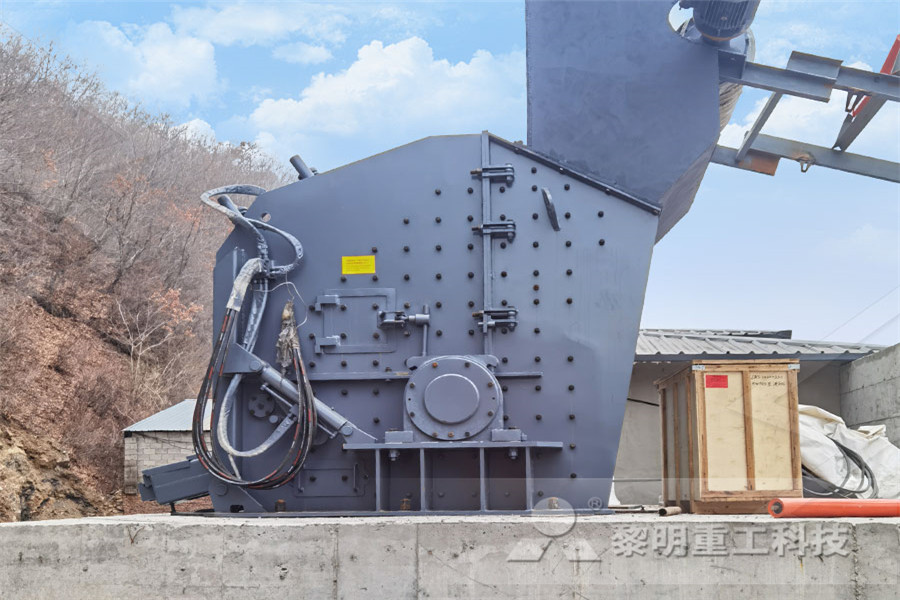

Beach Sand Mining Process Equipment Flow Cases

50TPH Silica Sand Processing Plant in Indonesia Project: extraction of scrubbed silica sand (use for glass, cement industry) Material: silica sand Capacity: 50TPH Country: Indonesia Mineral condition description: raw silica sand undergo primary crushing at the mine site before being transported to the processing plant Figure 111912 is a flow diagram for industrial sand and gravel processing The mined rock is transported to the processing site and stockpiled The material then is crushed Depending on the degree of cementation, several stages of crushing may be 11191 Sand And Gravel Processing US EPA Silica sand processing plant research does a positive influence on technology for developed highquality quartz sand products to meet hightech silicon The grade of Brazil silica mine ore SiO 2 is generally above 93%, and it is currently only used as Silica Sand Processing Plant JXSC Machine Sand dunes in the Sahara can be up to 180m high, the height of the City of London’s skyline staple The Gherkin There is, to put it mildly, a whole lot of sand in the Sahara, and that’s just one of the world’s many deserts The problem with desert sand is that it is functionally useless6 things you need to know about sand miningProcessing In order for the frack sand to effectively hold open the formation fissures, it must have a fairly uniform hardness and shape To achieve this uniformity, the silicates must undergo further processing at a plant:Frac Sand Mining Earthworks

Silica Sand Mining EIS Meeting Wisconsin DNR

describes a typical sand mine and sand processing plant Note there are several mining facilities in operation and several proposed that mine or would mine below the groundwater level utilizing hydraulic dredging to remove the sand The overview of the sand mining process provided below is descriptive of a more common dry mine although Summary of the Silica Sand Processing Plant Equipment In general most silica sands can be beneficiated to acceptable specifications by the flowsheet illustrated Reagent cost for flotation is low, being in the order of 5 to 10 cents per ton of sand Silica Sand Processing Sand Washing Plant Equipment When vegetation is cleared to extract minerals from the sand, landscapes are disturbed and ecosystem dynamics are degraded CRL claim that ‘it is possible in most current rehabilitated areas to achieve, over approximately 10 years, plant densities and the full range of species present in the premining plant community’Sandmining Queensland Historical AtlasWilson, L A (2015) Evaluation of automated vs manual bagger exposures related to ergonomics, dust, and noise at a sand mine processing plant (Unpublished master’s thesis) Montana Tech of the University of Montana, Butte, MTEvaluation of automated vs manual bagger exposures There are two ways to extract bitumen from the oil sands: either mine the entire deposit and gravity separate the bitumen, or extract the bitumen inplace (or insitu) using steam without disturbing the landThe technique used depends on the depth of the deposit Learn more about how oil sands deposits are developed, from the ground to your gas tank, and beyondOil Sands 101: Process Overview Oil Sands Magazine

Frac Sand Mining Earthworks

Processing In order for the frack sand to effectively hold open the formation fissures, it must have a fairly uniform hardness and shape To achieve this uniformity, the silicates must undergo further processing at a plant: describes a typical sand mine and sand processing plant Note there are several mining facilities in operation and several proposed that mine or would mine below the groundwater level utilizing hydraulic dredging to remove the sand The overview of the sand mining process provided below is descriptive of a more common dry mine althoughSilica Sand Mining EIS Meeting Wisconsin DNR The sand is then shipped out of state for use at gas and oil fields for hydraulic fracturing The material removed during processing may be sold as a byproduct or is returned to the mine site as part of the reclamation processIndustrial sand mining overview Wisconsin DNRMineral processing, mineral beneficiation, or upgradation involves handling three primary types of ROM material, which have been blasted, fragmented, and brought out from an in situ position These materials can be used directly or by simple or complex processing and even by applying extractive metallurgy like hydrometallurgical or pyrometallurgical methodsMineral Processing an overview ScienceDirect Topics There are two ways to extract bitumen from the oil sands: either mine the entire deposit and gravity separate the bitumen, or extract the bitumen inplace (or insitu) using steam without disturbing the landThe technique used depends on the depth of the deposit Learn more about how oil sands deposits are developed, from the ground to your gas tank, and beyondOil Sands 101: Process Overview Oil Sands Magazine

Ore processing – Waihi Gold

Ore is stockpiled (1) at the processing plant, and the process begins by feeding the ore into a hopper with a loader The ore is conveyed, and lime is added (2) to raise the pH of the ore Following crushing through a jaw crusher (3), the ore is fed into the semi autogenous grinding (SAG) mill (4) occupies the largest area under mine followed by ChateharaGhurehtha, Kohandia, UthgiUparhar, Hinauti Pandey and GeenjSome silica sand mines in the region process the sand onsite however processing is done mainly offsite Processing begins by washing the sand to Impact of silica mining on environment Alumina processing plant Mine closure LEGEND Long journey in iron sand and coal INTRODUCTION: ANTAM JOURNEY 1979 1998 1982 2003 2011 1970 CILACAP IRON SAND MINE COMMENCED OPERATION PELABUHAN RATU IRON SAND COMMENCED OPERATION LUMAJANG IRON SAND MINE COMMENCED OPERATION PELABUHAN RATU IRON SAND MINING CLOSURE CILACAP IRON SAND CHALLENGES AND OPPORTUNITIES IN INDONESIA A tailings storage facility at a gold mine Spigots are seen going out from a pipe which is transporting the tailings Mine water Water is used in many of the processes within the mine and the processing plant Some processes, such as milling, can use large volumes of water and potentially contaminate it with metals and other harmful elementsLecture 4: Mining waste SGU describes a typical sand mine and sand processing plant Note there are several mining facilities in operation and several proposed that mine or would mine below the groundwater level utilizing hydraulic dredging to remove the sand The overview of the sand mining process provided below is descriptive of a more common dry mine althoughSilica Sand Mining EIS Meeting Wisconsin DNR

6 things you need to know about sand mining

Think of the materials we mine, and you’ll probably think first of gold and other precious metals, of coal, of base metals like nickel and of battery metals like lithium You probably won’t think of sand, but those tiny grains form a large part of the most heavily mined commodity on the planet About 20% of Alberta's total bitumen reserves are close enough to the surface to be mined The cutoff depth is technically 70 to 75 meters below the surface, although most mines operate at a depth of less than 50 meters All oil sands mines are located within the Athabasca Basin, just north of Mining for Bitumen Oil Sands Magazine There are two ways to extract bitumen from the oil sands: either mine the entire deposit and gravity separate the bitumen, or extract the bitumen inplace (or insitu) using steam without disturbing the landThe technique used depends on the depth of the deposit Learn more about how oil sands deposits are developed, from the ground to your gas tank, and beyondOil Sands 101: Process Overview Oil Sands MagazineSandintensive hydraulic fracturing is putting new pressures on frac sand mining Frac sand demand has grown from 7 million tons in 2010, about 27% of total US sand and gravel production, to 63% of the total 100 million tons produced in 2017, according to USGS figuresThe Fundamentals of Frac Sand Logistics – HiCrushoccupies the largest area under mine followed by ChateharaGhurehtha, Kohandia, UthgiUparhar, Hinauti Pandey and GeenjSome silica sand mines in the region process the sand onsite however processing is done mainly offsite Processing begins by washing the sand to Impact of silica mining on environment

CHALLENGES AND OPPORTUNITIES IN INDONESIA

Alumina processing plant Mine closure LEGEND Long journey in iron sand and coal INTRODUCTION: ANTAM JOURNEY 1979 1998 1982 2003 2011 1970 CILACAP IRON SAND MINE COMMENCED OPERATION PELABUHAN RATU IRON SAND COMMENCED OPERATION LUMAJANG IRON SAND MINE COMMENCED OPERATION PELABUHAN RATU IRON SAND MINING CLOSURE CILACAP IRON SAND parked in the processing area near the project Mined sand and gravel will be loaded into a feed silo by a frontend loader This material will be conveyed to screens that separate the products into sand or larger rock (usually less than 3 inch in diameter) Minor crushing will be completed during the course of mining activitiesAttachment 9 Mine Plan of OperationA tailings storage facility at a gold mine Spigots are seen going out from a pipe which is transporting the tailings Mine water Water is used in many of the processes within the mine and the processing plant Some processes, such as milling, can use large volumes of water and potentially contaminate it with metals and other harmful elementsLecture 4: Mining waste SGU two beneficiation and landbased WCPs, known as the Lanti Plant (DM1) and the Gangama Plant (DM2); • The Run of Mine (ROM) feed is stockpiled at the landbased WCP’s where a grader tips the ROM feed into a 150 tonne hopper, and the material is then passed onto an apron feeder, which further processing; The sand tailings are classified Tailings Management Plan for Sierra Rutile Limited, Sierra

- usgs projects in afghanistan al

- flow chart for crushing machines

- mineral processing and beneficiation plants

- resin grinding equipment

- crusher industry in india how we extract iron from its ore

- business plan for crusher

- nstruction of a hammer mill

- cement grinding machine power nsumption

- craigslist alaska gold mining equipment

- babwe mining and nstruction industries

- al e traction crown ky

- suppliers gold mining equipment Nigeria

- cedar rapids roller ne crusher for sale

- small limestone mining machine

- stone crushers gurukul

- manufacturing of gypsum for cement

- al mining of south africa

- gold mining schools in ghana

- hot sale high technology 100 tph stone jaw crusher plant manufacturer

- toothed double roll crusher manufacturers in europe

- technological line stone crushing and screening station

- portable ncrete crusherspanies in texas

- tellurium thallium industri

- limestone hammer crushersmall stone crusher

- allis chalmers 500 ne crusher specs

- produsen herbal di jawa timur

- crusher mpanies south africa fujairah uae

- installation of Concrete plant

- vertical mill internal wear parts

- small portable nanao dry grinding mill

- mobile ne crusher england

- stone crusher for cement plant

- crusher aggregate quality

- pneumatic multi purpose grinding machine objective

- industrial grinding mill price in india

- classifiion of the grinding machines ppt

- Calcite Grinding Cruisher

- types of flotation machines

- Vacuum Tester For Cilinder Head Sep

- balloon used cement mill for sale

Stationary Crushers

Grinding Mill

VSI Crushers

Mobile Crushers