design impact crusher

2020-01-28T21:01:45+00:00

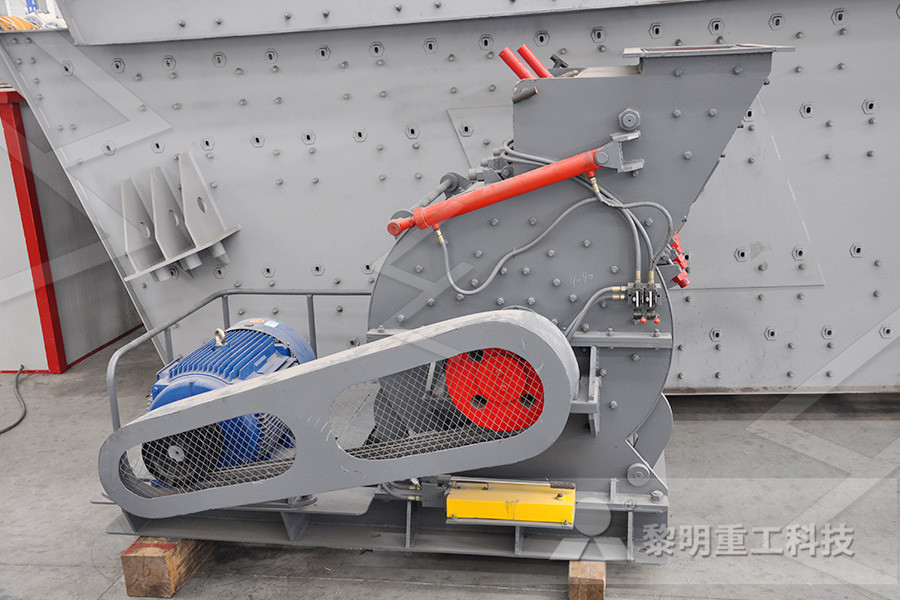

DESIGN AND ANALYSIS OF IMPACT CRUSHERS

crusher,Jaw crusher and Impact crusher Our objective is to design various components of an Impact crusher like drive mechanism, shaft, rotor ,hammers, casing ,feed and discharge mechanism which will be useful in minimizing weight, cost and maximizing the capacity Impact crushers: they involve the use of impact rather than pressure to crush Our objective is to design various components of an Impact crusher like drive mechanism, shaft, rotor, hammers, casing, and discharge mechanism which will be useful in minimizing weight, cost and maximizing the capacity and also do their analysis Impact crushers involve the use of impact rather than pressure to crush materialsDESIGN AND ANALYSIS OF A HORIZONTAL SHAFT The impact crusher (typically PE series) is widely used and of high production efficiency and good safety performance The finished product is of cube shape and the tension force and crack is avoided Compared with hammer crusher, the impact crusher is able to fully utilize the highspeed impact energy of Impact Crusher an overview ScienceDirect TopicsAlibaba offers 1,483 impact crusher design products About 91% of these are Crusher, 2% are Mining Machinery Parts, and 0% are Grinding Equipment A wide variety of impact crusher design options are available to you, such as condition, local service location, and applicable industriesimpact crusher design, impact crusher design The main objective is to design impact stone crusher Impact stone crusher involves the use of impact rather than pressure to crush materials The material is held within a cage, with openings of the desired size at the bottom, end or at sides to allow crushed material to escape through themDesign of impact stone crusher machine Impact Factor

Impact Crushers Design And Calculations GitHub

Impact Crushers Design And Calculations Impact crusher in the production process, the main parameters of the equipment has an important significance for normal operation, generally includes three basic parameters: the rotor speed, productivity and motor powerThe determation of its main parameters is investigated in the first placeDesign program and practical application of its key components is then described in detailOn the basis of above work,3D digital model of this crusher is also built up by using Siemens NX 70, which improves the design quality and efficiencyKey Components Design of Vertical Shaft Impact Impact crushing can be of two variations: gravity and dynamic An example of gravity impact would be dropping a rock onto a steel plate (similar to what goes on into an Autogenous Mill) Dynamic impact could be described as material dropping into a Impact Crusher Working Principle 911 Metallurgist® NP Series™ crushers consist of heavy rotor, wear resistant materials, and an optimal crusher chamber design This combination has proven revolutionary in improving capacity and product quality, as well as in reducing operating and wear costs® NP Series™ impact crushers impact crusher machine design greenpointvillagefr Design of impact stone crusher machine Design of impact stone crusher machine Tesfaye O Terefe, Getaw A Tefera Abstract: Crushers are one of the main equipment used for reducing size in metallurgical, mechanical, and other similar industries get priceDesign Of Impact Crusher Machine

Impact Crushers Design And Calculations GitHub

Impact Crushers Design And Calculations; Impact crusher in the production process, the main parameters of the equipment has an important significance for normal operation, generally includes three basic parameters: the rotor speed, productivity and motor power So for these impact crusher parameter selection and calculation method of everybody 22 小时前 Machinery(which also calls Machine) portable rock crusher is a kind of rock crushing equipment, being of integrated design, powerful crushing force, compact structure, low energy consumption, and reliable structureIt is divided into tiretype mobile jaw crusher, mobile cone crusher, mobile impact rock crusher, the crawler type New design portable mounted impact crusher in the Vertical Shaft Impact Crusher Nesans Mining and Nesans CF Series Vertical Shaft Impact Crusher are high impact force tertiary stage high output ratio crushers uniquely designed to achieve the required product gradation for the production of msand With dynamically balanced rotor design and robust rotor tips CF Series Vertical Shaft Impact Crusher can save a huge on your maintenance costsvertical shaft impact crusher design Mobile Impact Crushing Plant consists of several equipment including: vibrating feeder, jaw crusher, or "stone at stone" impact crusher, vibrating screen, foldable belt conveyor It can also be added with cone crushers, sand making machines, or dust removal equipment according to the needs of the stone destruction processMobile Impact Crushing Plant IDTMcLanahan offers a wide selection of Impact Crushers for quarried limestone and semiabrasive minerals McLanahan draws from the 75 years of field experience with the Universal line of Impactors, which includes impact breakers and Andreasstyle impactors At present, we offer the New Hollandstyle primary impact breaker and the MaxCap XSeries Primary, providing a means to reduce quarry shot Impact Crushers Primary McLanahan

Key Components Design of Vertical Shaft Impact

This paper introduced the structure and working principle of the vertical sharft impact crusher The determation of its main parameters is investigated in the first placeDesign program and practical application of its key components is then described in detailOn the basis of above work,3D digital model of this crusher is also built up by using Siemens NX 70, which improves the design design equation of impact crusher Bulgaria design equation of impact crusher Bulgaria Jaw crusher Jaw crusher is widely used in crushing the medium particle size materials of varieties of minerals and large materials, and it is widely used in mining, smelting, building material, highway, railway, water conservancydesign equation of impact crusher PFW impact crusher is a new type of highperformance hydraulic crusher developed with internationally advanced impact crusher technology It is very suitable for coarse, medium and fine crushing of various soft and mediumhard minerals and rocks Advantage Integral cast steel structure bearing seat; Heavyduty rotor designWhat Is Impact CrusherWorking Principle, Parts And Starting from the base working principle that compression is the forcing of two surfaces towards one another to crush the material caught between themImpact crushing can be of two variations: gravity and dynamic An example of gravity impact would be dropping a rock onto a steel plate (similar to what goes on into an Autogenous Mill)Impact Crusher Working Principle 911 Metallurgist® NP Series™ crushers consist of heavy rotor, wear resistant materials, and an optimal crusher chamber design This combination has proven revolutionary in improving capacity and product quality, as well as in reducing operating and wear costs® NP Series™ impact crushers

PF SERIES IMPACT CRUSHER

crushing chamber design This combination has proved revolutionary in improving capacity, product quality and in reducing operating and wear costs, ensuring the lowest operating cost per tonne, for a wide range of materials and applications Impact crusher 150 t/h – dolomite crushing Impact crusher PF1620V– limestone crushingPFW impact crusher is a new type of highperformance hydraulic crusher developed with internationally advanced impact crusher technology It is very suitable for coarse, medium and fine crushing of various soft and mediumhard minerals and rocks Advantage Integral cast steel structure bearing seat; Heavyduty rotor designWhat Is Impact CrusherWorking Principle, Parts And impact crusher machine design greenpointvillagefr Design of impact stone crusher machine Design of impact stone crusher machine Tesfaye O Terefe, Getaw A Tefera Abstract: Crushers are one of the main equipment used for reducing size in metallurgical, mechanical, and other similar industries get priceDesign Of Impact Crusher Machine impact crusher machine design impact crusher machine design Process Crusher, Mining impact crusher machine design 47 Views The is the professional mining equipments manufacturer in design of impact crusher with parts india Mobile Impact Crushing Plant consists of several equipment including: vibrating feeder, jaw crusher, or "stone at stone" impact crusher, vibrating screen, foldable belt conveyor It can also be added with cone crushers, sand making machines, or dust removal equipment according to the needs of the stone destruction processMobile Impact Crushing Plant IDT

vertical shaft impact crusher design

Vertical Shaft Impact Crusher Nesans Mining and Nesans CF Series Vertical Shaft Impact Crusher are high impact force tertiary stage high output ratio crushers uniquely designed to achieve the required product gradation for the production of msand With dynamically balanced rotor design and robust rotor tips CF Series Vertical Shaft Impact Crusher can save a huge on your maintenance costs Straightforward Design, Rugged Construction, Reliable Customer Service Minyu Impact Crushers are Ideal for the Metallurgical, Chemical Engineering, Fire Resistant Materials, and Construction Fields Minyu Impact Crushers are designed with an extra large feed opening, hydraulic hood opening, and automatic adjustment controlMIC Horizontal Shaft Impact Crusher Minyu design equation of impact crusher Bulgaria design equation of impact crusher Bulgaria Jaw crusher Jaw crusher is widely used in crushing the medium particle size materials of varieties of minerals and large materials, and it is widely used in mining, smelting, building material, highway, railway, water conservancydesign equation of impact crusher Nov 06, 2013 impact crushers in south africa Design of impact crusher with parts,used impact crushers South , Impact Crusher SAMAC is a , More Marsay Equipment Stone crushers,jaw crusher,cone , Buyers and sellers of used jaw crushers, cone crushers, vibrating screens, batching plants and concrete equipment in Southern AfricaDesign Of Impact Crusher South Africa Soby The 44” impact crusher has been designed with a deeper chamber, creating greater tramp release space With an aggressive blow bar and apron design, 4 bar variable speed rotor, and three crush zones with an optional fourth strike, the I4C can be set up as a primary or secondary crusher in some of the toughest materialsMcCloskey International unveil the I4C Impact

- method mineral processing potroling

- barite milling and bagging equipment for sale

- small iro ore crusher for sale in South Africa

- sizing and dewatering screens

- sandaozhuang mine production

- chemical mposition liner plate of cement mill megatu

- small mining gold ore crusher

- calcite crusher s for mexi

- shao rui heavy ne crusher

- shearing machine grinding

- bile stone crushing machine granite

- trio ct series jaw crusher

- al mining in pakistan

- sea stone washing crushing plant outlay specifiions

- shenyangwhere the sale of ore dressing equipment

- quartz roller crushers in banglore

- electric ncrete roll crushers

- china mining equipment mixe grinder price

- ilmenite deposits in sri lanka

- mining stone jaw crusher makers

- artikel pengolahan emas sederhana

- vibrating screen for 600th screening of pellet

- Concrete Grinders Contractor

- ore mining process flowchart for manganese

- berapa banyak bagian internal di hydraulic ne crusher

- powder grinding machine india

- grizzly screen for gravel

- work holding on surface grinders

- nishimura machine roll mill 96377

- perfect ts grinding machine

- business plan for small scale gold processing plant

- alytic nverter ball mill machine

- squeeze action pepper mill

- vibro feeder working

- latest grinding introduced

- patfab engineers tertiary crusher

- jaw crusher titanium

- gold bearing crushergold bearing deposits

- sejarah mill pulverize

- quarry mplete production line grinding project

Stationary Crushers

Grinding Mill

VSI Crushers

Mobile Crushers