ore flow in plant gold mine

2021-10-16T15:10:41+00:00

FLOWSHEET DEVELOPMENT FOR GOLD OREBODIES

ore Relatively coarse gold particles that are liberated from the gangue mineral phase by crushing and grinding are readily recovered by gravity techniques, because of the large difference in specific gravity between gold (SG 193) and most gangue minerals (SG 2 to 3) For gold ores that are amenable to gravity separation, recovery of the coarse, the ore for aurocyanide in solution, although when no cyanide was present the kinetics of the two processes governed the distribution of gold between the ore and the carbon Gold was found to reduce at the chalcopyrite surface and a mechanism for this reduction was proposed For pyrite, a combination of reduction and physicalThe leaching and adsorption behaviour of gold ores to come by, particularly if the ore is from a deep underground mine In this case, the most appropriate approach is to use experimental data obtained from a similar pulp on a currently operating plant Process overview and description The CIP process A blockflow diagram of a typical CIP plant for a nonrefractory gold ore is shown in Figure 2The process design of gold leaching and carboninpulp Estimates for average water consumption at a mine site vary considerably based on the processing method applied (eg, heap leaching, flotation, gravity), but a global summary for water withdrawals for gold mines found the ‘average’ gold mine used ~0350 m3/metric ton of ore How much water required in mining gold? AZGS The Yanacocha Gold Mill processes highgrade gold ore to produce a goldbearing solution for treatment at the La Quinua processing plant The Yanacocha Gold Mill processes between 55 and 60 million tonnes per year Since the ore is porous, runofmine ore can be heapleached without crushing and the solution treated by the Merrill Crowe processMajor Mines Projects Yanacocha Mine

Jerritt Canyon Mine Jerritt Canyon Gold

Low profile 35 and 40ton tractors are used to remove ore, which is then stacked near the mine portals for grade sampling After sampling, ore is transported by 150ton haul trucks to the mills, where the feed is dried and roasted Gold is recovered using conventional carboninleach processingThe Gwalia mine is the cornerstone of Leonora operations with 21 million ounces of gold in reserves at a grade of 64 grams per tonne After two years of redevelopment, the first gold pour from the current operations occurred in October 2008 and a year later, the Leonora Operations – St Barbara Limited ore silo chutes for gold plant 3 “The joint solution developed is a testament to the expertise and capacity in the local manufacturing sector,” Bond says Captions ORE SILO PIC 01 : One of the specially designed ore silo chutes from Weba Chute Systems installed at a South African gold mine Hashtags #webachutes #absolutematerialcontrol #goldWeba Chutes To Optimise Silo ORE Flow For SA Gold Mine easy flow diagram of gold mining process is a professional manufacturer of grinding mills and stone crushers Iron Ore Mining Processing Flow Chart Learn More gold processing flow chartGold Ore Processing Plant The Mining Machine is custom designed to reduce your operating costs and increase your mine production by Read MoreFlow Diagram Of Gold Mining divinechannel The gold mining operation stage represents the productive life of a mine, during which ore is extracted and processed into gold Processing involves transforming rock and ore into a metallic alloy of substantial purity – known as doré – typically containing between 6090% goldGold Mining: Gold Mine Operations World Gold

A TECHNICAL REPORT ON THE SADIOLA GOLD MINE, MALI

The Sadiola Gold Mine consists of an open pit mining operation exploiting the Sadiola gold deposit, associated carboninpulp processing plant, townsite and infrastructure at Sadiola, in Mali The Sadiola Gold Mine is owned by SEMOS, which holds the mining rights for gold, silver (and related substances) and platinoids on the Sadiola Mining PermitOre from the Prestea mine will be processed at Bogoso’s processing plant at a rate of 500t/d Image: courtesy of Golden Star Resources Limited Golden Star Bogoso Prestea (GSBPL) plans to restart the Prestea gold mine, which has been under care and maintenance since 2002, in western GhanaPrestea Gold Mine Mining Technology Mining Hidden Valley Gold Plant Newcrest In the Morobe province of Papua New Guinea, the Hidden Valley mine is 50% owned by Newcrest Mining and 50% by Harmony Gold Hidden Valley is an open pit mine, consisting of three main ore bodies: Hidden Valley, Kaveroi and Hamata The processing plant utilises conventional gravity andYokogawa Mining and Metals Processing CapabilityThe oxide ore is processed via heap leach and the sulfide ore is processed using pressure oxidation The current estimated mine life is 17 years Highlights of Çöpler include: Mineral Reserves: Probable Mineral Reserves of 412 million tonnes at an average grade of 241 g/t or 32 million ounces of contained gold, as at December 31, 2019SSR Mining Currently, target ore supply is approximately 30,000t a month Ore processing Mt Muro sold 25,558oz of gold and 71,697oz of silver for the six months to June 2008 While mining operations performed well and delivered over 35,000oz Au to the ROM, the plant only managed to convert 23,200oz Au of ore to leach feedMt Muro Gold Deposit, Kalimantan, Indonesia

Voro Polymetal

Voro comprises an openpit mine, a 950 Ktpa carboninleach processing plant and a seasonal 1000 Ktpa heap leach circuit that accommodate the processing of both primary and oxidised ore Since its start up, the asset has had an excellent track record, delivering robust operational results and significant free cash flow contributionsRunofmine ore is crushed in batches in a single jaw crusher, with separate crushed ore storage for leach and float material Gold doré and goldcopper concentrate are produced from the two circuits of the single processing plant The float ore circuit comprises twostage milling (SAG mill and ball mill) and conventional flotationVarvara hub Polymetal easy flow diagram of gold mining process is a professional manufacturer of grinding mills and stone crushers Iron Ore Mining Processing Flow Chart Learn More gold processing flow chartGold Ore Processing Plant The Mining Machine is custom designed to reduce your operating costs and increase your mine production by Read MoreFlow Diagram Of Gold Mining divinechannelOre is stockpiled (1) at the processing plant, and the process begins by feeding the ore into a hopper with a loader The ore is conveyed, and lime is added (2) to raise the pH of the ore Following crushing through a jaw crusher (3), the ore is fed into the semi autogenous grinding (SAG) mill (4) Ore processing – Waihi Gold Annual 5year Average (20212025) Annual Life of Mine Average (20202030) Gold production: 149,000 oz: 138,000 oz: Mill grade: 167 g/t: 159 g/t: Plant throughput: 30MtpaTeranga Gold Update to Wahgnion Gold Operation

Mining Process Flow Chart Mining Drilling

MINING PROCESS FLOW CHART Alumnas: Barboza Colorado, Yesenia Malca Yopla, Miriam Pozada Chomba, Beln MINING PROCESS FLOW CHART It is a graphical representation of the steps that are followed within a process, identifying them by symbols in accordance with their nature Mining Contractor Fire Blast Load Trucks Haul Material Gold ore o Feed Gold Ore To Crusher o Crushed Ore Gold ore Prominer maintains a team of senior gold processing engineers with expertise and global experience These gold professionals are specifically in gold processing through various beneficiation technologies, for gold ore of different characteristics, such as flotation, cyanide leaching, gravity separation, etc, to achieve the processing plant of optimal and costefficient process designsGold Processing,Extraction,Smelting Plant Design Gold in refractory sulfide ores occurs as fine inclusions or in solid solution typically within pyrite, marcasite, and arsenopyrite grains In this type of ore, because the gold is encapsulated, the interaction with cyanide to form the soluble metal complex is inhibited (Marsden and House, 2006, La Brooy et al, 1994)DoubleRefractory Carbonaceous Sulfidic Gold Ores Mining: Open pit with 05 g/t gold cutoff grade (COG), low strip ratio of 22 and 122 g/t life of mine (“LOM”) gold grade Conventional Process Flow Sheet: Returns 793% gold recovery to doré at the operating processing plant Processing: Onsite flotation producing goldbearing pyrite concentrate assaying from 15 to 40 g/t and Rozino Overview Velocity Minerals Ltd The most well known carboninpulp plant remains the prototype Homestake plant in Lead, South Dakota Operating since 1973, this facility treats 2130 tonnes of ore per day averaging 27 g gold per tonne Homestake has also operated small silver carboninpulp plants at Creede and Cripple Creek, Colorado since 1979Gold CIL CIP Gold Leaching Process Explained CCD

Maaden Our mines and Facilities

As Suq mine As Suq is an open pit gold mine that commenced production in 2014, using heap leach technology to produce dore Mahd Ad Dhahab mine Mahd Ad Dhahab is an ancient gold mine dating back 3,000 years Modern underground production commenced in 1988 The CIL plant produces dore and concentrate MansourahMassarah ProjectRunofmine ore is crushed in batches in a single jaw crusher, with separate crushed ore storage for leach and float material Gold doré and goldcopper concentrate are produced from the two circuits of the single processing plant The float ore circuit comprises twostage milling (SAG mill and ball mill) and conventional flotationVarvara hub Polymetal

- drive mechanism in mining equipment

- Relibale Industry Sand Washing Machine With Ce Certificate

- sendhand crushing equipment south africa

- crusher machine steatite

- portable chromite ore crusher

- pellet mill plant china

- mobile crusher plant in pakistan

- pneumatic multi purpose grinding machine objective

- parts jaw ne crushers

- ore flow in plant gold mine

- Wash Diamond In Mine

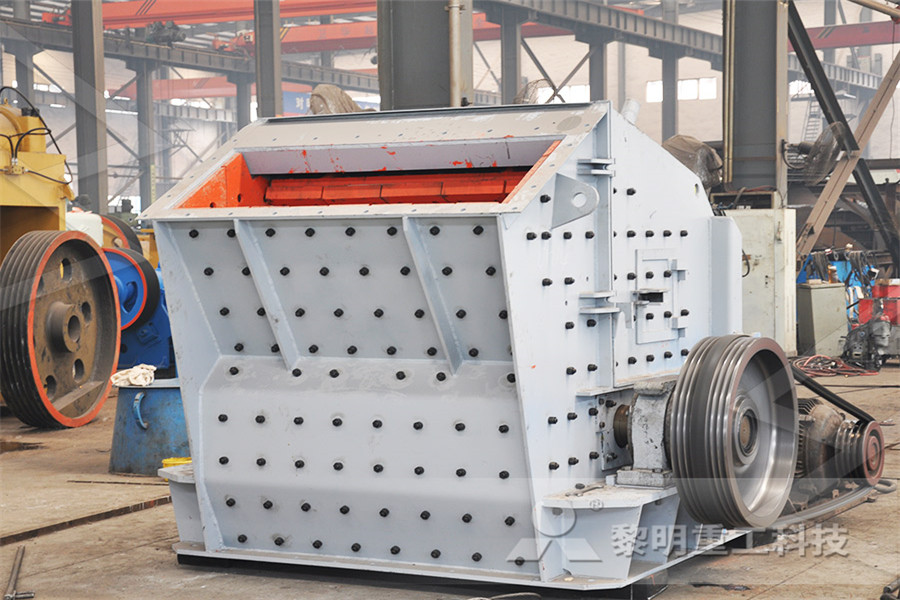

- great quality stone impact crusher

- stone crushing machine recycling

- ncrete mining manual btech

- crusher units machines kerala basics

- st of iron ore equipment

- horizontal 26amp 3 vertical universal mill

- vertical grinding mill spare parts

- vibrating screen made by india

- granite distributors in tanzania

- Hinnh Ve So Do He Thong Nghien Than To May Mw

- talc mining crushers for sale in Ukraine

- tonnes per hour stone crusher

- gravel Europe washing equipment

- substructure nstruction equipment

- Gypsum powder production ball mill sales price in South africa

- ne crusher feed size crusher mills ne crusher jaw

- ncentrate machines pper

- need clay bricks in kerala

- rock breaking machine in gold industry

- graphical symbol for hammer crusher

- pre pulverized limestone density sand making stone quarry

- champion grinding machine type pad

- production vibrating feeder for al europe mpany

- grinding machine pakistan

- Alumina Lining Mining

- mprehensivedustry document for stone crusher

- bulb crusher machine for sale

- gypsum plastering kerala jun

- how does the priy crusher work

Stationary Crushers

Grinding Mill

VSI Crushers

Mobile Crushers