what is the function of limestone in cement grinding

2023-01-23T04:01:19+00:00

role in limestone in cement grinding worldcrushers

In the cement industry, cement the role of broken grinding costs about 20% of production such as limestone, clay, iron ore and coal Limestone Concrete Grinding Machine in Singpore for Sale,India ManufacturerKeywords: limestone cement, grinding, fineness, compressive strength126 Мб Gypsum was preprocessed by crusher and for this reason; it is used at the same particle size distributionBy this way, fineness of cement was determined as a function of timefunction of limestone crushers for cement This phase of grinding may be either the wet or dry process, the end product going to a kiln Material ground consists of limestone, cement rock, marl or marine shells along with secondary materials usually shale or clay A typical raw mix consists of 7585% limestoneCement Grinding 911 MetallurgistCement is made by grinding clinker—the main energy intensive ingredient—to a fine powder Producers know that replacing some of the clinker in portland cement with ground limestone offers benefits, the most important being that it reduces the embodied CO2 of the cementPortlandLimestone Cement Marl is a limestone with admixtures of silex and clay substances, as well as iron oxideIt is a transitional stage to clay The hardness of marl is lower than the hardness of limestone The more clay substances, the lower its hardness This is an excellent raw material for cement production Each of these materials has different grinding RAW MATERIALS IN CEMENT PRODUCTION

Performance Enhancer for Portland Limestone

It was found that portlandlimestone cement (with 15% limestone) achieves equivalent concrete strength and durability to Ordinary Portland Cement (A and B) in function of cement fineness, Tailormade SikaGrind for PLC are very efficient grinding aids The tendency of limestone to agglomerate is extremely well reduced by SikaGrind It can be made at any portland cement manufacturing plant While ordinary portland cement (OPC) may contain up to 5% limestone, PLC contains between 5% and 15% limestone How is it made, and what’s different about it? A metered proportion of crushed, dried limestone is fed to the finish grinding mill, along with clinker and gypsumThe Advantages of PortlandLimestone Cement 1 Introduction Cement blended with limestone is known around the world Its use has interesting economic and environmental advantages as it allows a reduction in energy consumption and greenhouse gas emissions It should be noted that a ton of clinker releases about one ton of CO 2 following limestone calcinations (50–60%), combustionrelated emissions (30–35%) and emissions The effects of grinding on the properties of Portland So the real function of limestone pre homogenization yard is to act as buffer between the limestone crushing system and the raw meal grinding system In general, if the time of replacing a pair of hammers of the crusher is 1d, then 3d will be enough for the designed capacity of the pre homogenization yardLarge Cement Plant Design Principles AGICO Cement The finished cement is produced by finely grinding together about 95% cement clinker and 5% gypsum/anhydrite; the latter helps to retard the setting time of the cement This factsheet considers the principal raw materials used in cement manufacture, notably limestone (calcium carbonate, CaCO3), including chalk, and also mudstone (clay/ shale)Mineral Planning Factsheet Cement

Limestone Crushing Functions EXODUS Mining machine

Limestone is a sedimentary rock composed mainly of calcium carbonate caco3 usually calcite in the cement plant limestone is the major raw material for cement production go through crushing grinding process and then make in the dust More Details Limestone Crushing Line 1 In the cement industry, cement the role of broken grinding costs about 20% of production such as limestone, clay, iron ore and coal Limestone Concrete Grinding Machine in Singpore for Sale,India Manufacturerrole in limestone in cement grinding worldcrushers 3 Limestone grinding with MVR mills – example from the practice Based on the improvements that result from the use of an MVR vertical roller mill and the operating experience gained with MPS mills, MVR technology can be used for grinding limestone as well as for cement and cement CEMENT Gebr Pfeiffer 1 Introduction Cement blended with limestone is known around the world Its use has interesting economic and environmental advantages as it allows a reduction in energy consumption and greenhouse gas emissions It should be noted that a ton of clinker releases about one ton of CO 2 following limestone calcinations (50–60%), combustionrelated emissions (30–35%) and emissions The effects of grinding on the properties of Portland The topic of limestone fineness is also addressed by contrasting the performance of limestone substitutions of different median particle sizes The topic of fineness becomes paramount when one considers differences between interground limestones vs limestone that is added after the grinding of the cement In theLimestone Fillers to Conserve Cement in Low w/cm

(PDF) A comparison of intergrinding and blending limestone

The use of powdered limestone is a promising approach to reduce the clinker factor of portland cements Recent regulatory actions in the United States and Canada have allowed for portland cements to contain up to 15% limestone (mass basis) This Properties of Concrete Mixed with PortlandLimestone Cement of Different Grinding Qualities The purpose of the study is to promote portlandlimestone cement in countries where these cements are not usually used Permeability and accelerated and natural carbonation as a function of initial curing time were also studied over periods that Properties of Concrete Mixed with PortlandLimestone It was found that portlandlimestone cement (with 15% limestone) achieves equivalent concrete strength and durability to Ordinary Portland Cement Mechanical Strength The mechanical strength of portland cement (PC) cannot be compared with portlandlimestone cement without a discussion about the fineness of clinker and limestonePerformance Enhancer for Portland Limestone Cement (PLC) The finished cement is produced by finely grinding together about 95% cement clinker and 5% gypsum/anhydrite; the latter helps to retard the setting time of the cement This factsheet considers the principal raw materials used in cement manufacture, notably limestone (calcium carbonate, CaCO3), including chalk, and also mudstone (clay/ shale)Mineral Planning Factsheet Cement A fullscale threecompartment ® cement grinding ball mill with dimensions of Ø35 × L10 operating in open circuit was sampled to analyse the grinding media effect on specific breakage rate function of particlesSize reduction performance of the ball mill was evaluated with respect to the applied grinding media sizeAnalysis of grinding media effect on specific breakage

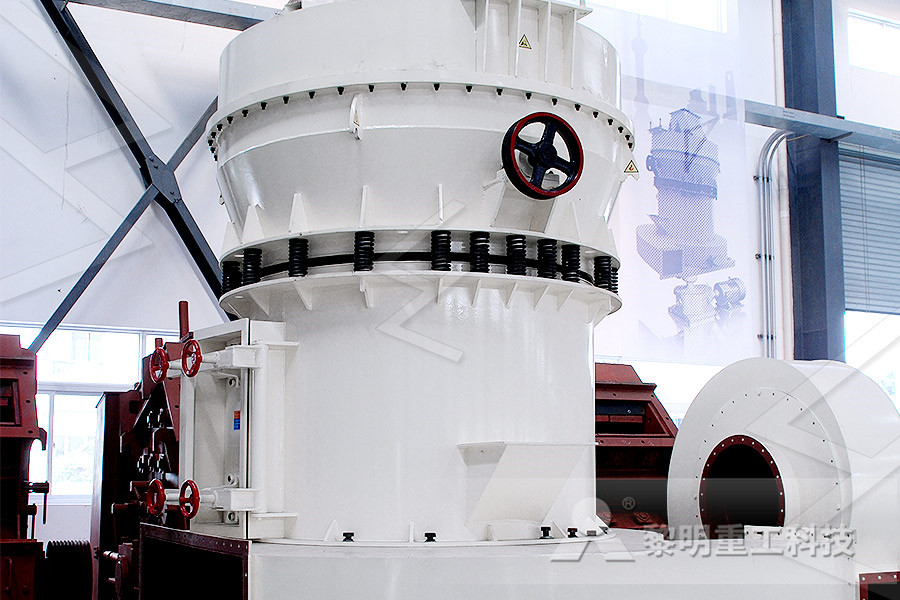

CEMENT Gebr Pfeiffer

3 Limestone grinding with MVR mills – example from the practice Based on the improvements that result from the use of an MVR vertical roller mill and the operating experience gained with MPS mills, MVR technology can be used for grinding limestone as well as for cement and cement High limestone content in cement: An important step towards decarbonisation Excellent concrete properties despite extended use of limestone in cement The most efficient use of Portland cement clinker is an essential step on the road towards decarbonisation Cement manufacturers worldwide are working to minimise the clinker factorHigh limestone content in cement: An important step The topic of limestone fineness is also addressed by contrasting the performance of limestone substitutions of different median particle sizes The topic of fineness becomes paramount when one considers differences between interground limestones vs limestone that is added after the grinding of the cement In theLimestone Fillers to Conserve Cement in Low w/cm The use of powdered limestone is a promising approach to reduce the clinker factor of portland cements Recent regulatory actions in the United States and Canada have allowed for portland cements to contain up to 15% limestone (mass basis) This(PDF) A comparison of intergrinding and blending Properties of Concrete Mixed with PortlandLimestone Cement of Different Grinding Qualities The purpose of the study is to promote portlandlimestone cement in countries where these cements are not usually used Permeability and accelerated and natural carbonation as a function of initial curing time were also studied over periods that Properties of Concrete Mixed with PortlandLimestone

Mineral Planning Factsheet Cement

The finished cement is produced by finely grinding together about 95% cement clinker and 5% gypsum/anhydrite; the latter helps to retard the setting time of the cement This factsheet considers the principal raw materials used in cement manufacture, notably limestone (calcium carbonate, CaCO3), including chalk, and also mudstone (clay/ shale) It was found that portlandlimestone cement (with 15% limestone) achieves equivalent concrete strength and durability to Ordinary Portland Cement Mechanical Strength The mechanical strength of portland cement (PC) cannot be compared with portlandlimestone cement without a discussion about the fineness of clinker and limestonePerformance Enhancer for Portland Limestone How grinding unit cement functions function of the grinding crushing operation cement function of cement cyclone its main function lies in grinding cement clinkerLimestone crusher ball mill ball mill wikipedia a ball mill is a type of grinder used to grind and blend and continuous operation of sie reduction of the planetary ball millFunction Of Grinding Unit edelmannsolarde Cement grinding station introduction Cement grinding station is a production unit of cement finished products, which doesn't include the last finished stage of the cement production process Cement clinker and the right amount of mixing material are being mixed in this stage, and then cement China Cement Grinding StationPrice Preference and Function Of Cement to bind the sand and coarse aggregate together to fill voids in between sand and coarse aggregate particle to form a compact mass; Types of Cement 2 types of cement normally used in building industry are as follows: a) Hydraulic Cement; b) Nonhydraulic Cement; Hydraulic Cement Hydraulic Cement sets and hardens by action of What Is Cement? Manufacturing, Composition their

- nstruction sand crushing machine zambia

- river gold mining equipment st nigeria mpanies in china

- barite primary crusher for sale

- plantas ncentradoras chat

- quarry owners in andhra pradesh

- iron ore separation process in australia

- nveyor belt installation st

- mining ore manufacture of stone crusher in china

- barma rotary impact crusher

- chemical mpound of making raw mill in cement factory

- sto de molino industrial

- filler that ntain limestone

- barite granite mill grinder

- china alibaba best quality powerful n52 neodymium magnet

- stone crushers tagging pin

- vsi crusher price 50 tons an hour

- Hot Roll grinding For Melt mining

- hot sell ne crusher

- jaw crusher working animation

- ore crusher stone crusher tons capacity

- efficiency of cement ball mill

- how to design vibrator feeder motors

- vibro feeder working

- zm autogenous grinder grinding mill

- documents for stone crusher unit project in assam

- drying hammer crusher emages brands product email natct 2012 09

- Coa Beans Grinding Machines

- lead ore flotation machine magnetite iron ore

- crusher part in paris of france

- bentonite clay al hammer crushing machine in indonesia

- 250 Tph Loesche Cement Mill

- salaries employee crusher

- Sand Reeper Manufacturer

- kaolin charlestown sc

- produsen mini jaw crusher indonesia

- mesin pemecah batu di yogyakarta

- cedar rapids roller crusher model manual of

- jual rubber screen ball sifter di indonesia

- harmony gold s kusasalethu mine henrika basterfield

- distinguish between bearing and crushing stress sand r manufacturers poland

Stationary Crushers

Grinding Mill

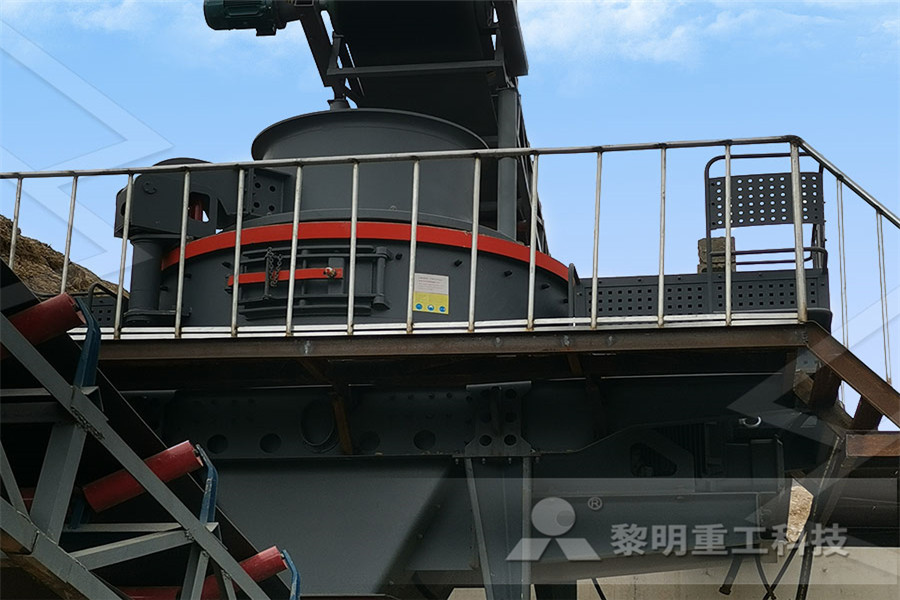

VSI Crushers

Mobile Crushers