low grade iron ore ncentration equipment

2020-02-26T12:02:23+00:00

low grade iron ore beneficiation process solution for

Sep 25, 2018 Low grade Iron Ore Beneficiation and the Process of Jigging Iron ore resources are getting consumed at an accelerated rate because of the growth in the production of iron and steel Due to this reason the availability of high grade iron ore is reducing and the supply of high grade iron ore to iron and steel plants is declining concentration, density, gangue material, gravity separation, iron ore beneficiation, Jig, Jigging, Low grade iron ore, Low grade Iron Ore Beneficiation and the Process of Jigging Iron ore resources are getting consumed at an accelerated rate because of the growth in the production of iron Low grade Iron Ore Beneficiation and the Process of A water slurry of an iron ore concentrate from primary concentration equipment, for example, magnetic separators, such as is produced in a closedcircuit crushing and grinding operation, contains coarse high grade mineral particles, coarse low grade middling particles, and relatively fine high grade mineral particles and can contain a minor METHOD FOR PROCESSING IRON ORE The results of this study demonstrated that lowgrade iron ore fines can be upgraded by means of STET triboelectrostatic belt separator Based on STET experience, the product recovery and/or grade will significantly improve at pilot scale processing, as compared to the benchscale test device utilized during these iron ore trialsDry Iron Ore Beneficiation Iron Ore Separation ST LowGrade LeadZinc Concentration Jig Machine Floatation separation and floatation separator is mainly involved for leadzinc ore beneficiation because the enrichment efficiency of leadzinc ore by floatation separation is high with mature flow sheet, and most leadzinc ore is extracted by floatation separationLowGrade LeadZinc Concentration Jig Machine

Open Access Recovery Improvement of Fine Iron Ore

This study was performed on a lowgrade iron ore namely goethiticlateritic ore (GLO) from Eastern India Detailed mineralogical, physical and chemical characteristics of a goethiticlateritic iron ore showed that the sample contained porous and friable oxides and hydroxides of iron The ore sample had a feed grade of 5443% total Fe, 927% SiO promoted to an iron ore concentrate assaying 6189% Fe with 9382% recovery, while the iron grade of the tailings was 738% [ 29 ] In the 1960s, on the basis of the above test equipment, the Anshan Iron Steel Company developed a “reverse U” type twophase fluidized roaster with a handing capacity of 700 t/d, as presented in Fig 3 [ 30 ]Fluidized bed roasting technology in iron ores dressing in Sulfide ore grades range from 0158% Ni, with 93% of known deposits ranging from 022% Ni All nickel ores have relatively low nickel content, the classification is as follows: highgrade nickel ore has Ni content greater than 18%, middlegrade nickel ore has Ni content between 1317%, lowgrade nickel ore Enhanced methods for nickel recovery from low Indian Iron Ore Scenario : Low Grade Iron Ore Beneficiation Anand Kumar, Manager (mining), Omendra Singh, Design Engineer (Mining) MECON Limited, Ranchi 834 002 : Abstract Wide reserves of iron ore is found in India which is the basic raw material for iron and steel industryIndian Iron Ore Scenario : Low Grade Iron Ore BeneficiationTwo fine lowgrade iron ores were used in this series of tests The first ore consisted of an ultrafine Fe ore tailings sample with a D50 of 20 µm and the second sample of an itabirite iron ore sample with a D50 of 60 µm Both samples present challenges during their beneficiation and cannot be efficiently processedDRY BENEFICIATION OF LOWGRADE IRON ORE FINES

RBSSN

Most of the surrounding mines in the area had similar quantities of subgrade iron ore, which everyone thought was unusable Plants are designed to upgrade the Lowgrade Fine size and coarse size range of materials This upgradation is achieving through the use of various process equipment’s Following Main equipment’s are in Our The technology is based on concentration of lowgrade barite ore (sp gr 39) by gravity and flotation methods The lowgrade ore is upgraded to marketable grade product with sp Gr 41 The process also enables processing of offgrade mine waste dumps for suitable industrial applications 5 Level/Scale of Development Pilot scale, 10 tpdBeneficiation of Lowgrade Baryte Ores CSIRNML Roy S, Das A (2008) Characterisation and processing of lowgrade iron ore slime from the jilling area of India Miner Process Extr Metall Rev 29(3):213–231 Article Google Scholar 11 Jena SK, Sahoo H, Rath SS, Rao DS, Das SK, Das B (2015) Characterization and processing of iron ore slimes for recovery of iron valuesCharacterization and Comminution Studies of LowGrade Low grade iron ores cannot be used as such for the production of iron and steel and need to be upgraded to reduce its gangue content and increase its Fe content The process adopted to upgrade the Fe content of iron ore is known as iron ore beneficiation (IOB)Beneficiation of Iron Ores – IspatGuru Fig 1 shows the particlesize distribution of the iron ore jigging tailings sample and the concentration feed sample (grinding/classification at 14 mm)As observed, the d 80 of the tailings sample is approximately 4000 μm (4 mm) with only 4% of the particles below 37 μm (0037 mm) The d 80 of the concentration feed sample is 840 μm (0840 mm), with only 4% of particles below 10 μm (0 Characterisation and magnetic concentration of an iron ore

The Testing and Concentration of a Low Grade Copper

THE TESTING AND CONCENTRATION OF A LOW GRADE COPPER NICKEL ORE By Laurence T Eck Submitted to the Department of Mineral Dressing in Partial Fulfillment of the Requirements for the Degree" of Bachelor of Science in Metallurgical Engineering MONTANA SCHOOL OF MINES BUTTE, MONTANA MAY, 1940 NTANASCHeOlOf INESII rRY Abstract: This study focused on the extraction of nickel from a lowgrade lateritic ore The characterization of representative samples was done by Xray diffraction (XRD), Xray fluorescence (XRF), and microscopic mineralogical studies Nickel was uniformly distributed in iron Atmospheric pressure leaching of nickel from a lowgrade ore, metalbearing mineral mass that can be profitably mined Nearly all rock deposits contain some metallic minerals, but in many cases the concentration of metal is too low to justify mining mining, extraction of solid mineral resources from the earthOres Article about Ores by The Free Dictionary Indian Iron Ore Scenario : Low Grade Iron Ore Beneficiation Anand Kumar, Manager (mining), Omendra Singh, Design Engineer (Mining) MECON Limited, Ranchi 834 002 : Abstract Wide reserves of iron ore is found in India which is the basic raw material for iron and steel industryIndian Iron Ore Scenario : Low Grade Iron Ore BeneficiationNiton analyzers can determine the composition of the iron ore and other base metal deposits (Fe, Cu, Pb, Zn, Ni, Co) Bauxite: The ability to grade bauxite, the primary source of aluminum ore, by measuring penalty elements such as silicon (Si) and iron (Fe) is critical for Mineral Rare Earth Elements Analyzer Thermo

Technical Resource Multotec

Statistical analysis and concentration of iron ore using Longi LGS 500 WHIMS A Longi LGS 500 wet high intensity magnetic separator (WHIMS) was used to concentrate a fine, low grade The lowgrade sections of the ore body were blasted less intensely, so the waste was preferentially distributed to coarse fragments The ore was then mined, crushed and screened so that the finer, highergrade particles reported to the processing plant; whilst the coarser, lower grade Unearthing hidden value using preconcentration THE TESTING AND CONCENTRATION OF A LOW GRADE COPPER NICKEL ORE By Laurence T Eck Submitted to the Department of Mineral Dressing in Partial Fulfillment of the Requirements for the Degree" of Bachelor of Science in Metallurgical Engineering MONTANA SCHOOL OF MINES BUTTE, MONTANA MAY, 1940 NTANASCHeOlOf INESII rRYThe Testing and Concentration of a Low Grade Copper Abstract: This study focused on the extraction of nickel from a lowgrade lateritic ore The characterization of representative samples was done by Xray diffraction (XRD), Xray fluorescence (XRF), and microscopic mineralogical studies Nickel was uniformly distributed in iron Atmospheric pressure leaching of nickel from a lowgrade Sulfide ore grades range from 0158% Ni, with 93% of known deposits ranging from 022% Ni All nickel ores have relatively low nickel content, the classification is as follows: highgrade nickel ore has Ni content greater than 18%, middlegrade nickel ore has Ni content between 1317%, lowgrade nickel ore has Ni content between 0612%Enhanced methods for nickel recovery from low

Major Mines Projects Tilden Mine

First ground to a fine powder, the ore is next concentrated using magnetic separation and flotation to 60 to 65 % iron, then rolled into 3/8" dia pellets that are purplishgrey when they emerge, steaming, from the plants Turning lowgrade crude ore into highgrade concentrate requires a means of separating the iron particles from the waste rock Today, mine operators in Michigan’s Upper Peninsula are generally after taconite, a lowgrade ore that was once considered waste rock To make it usable, mining companies blast it into small pieces with explosives, grind it into powder with powerful machinery, and then use magnets or flotation techniques to separate the iron minerals out from Iron Mines in Michigan NASA Earth Observatoryore, metalbearing mineral mass that can be profitably mined Nearly all rock deposits contain some metallic minerals, but in many cases the concentration of metal is too low to justify mining mining, extraction of solid mineral resources from the earthOres Article about Ores by The Free Dictionary

- sand crusher to powder machine

- manganese slag wool production

- robo sand making project South Africa

- impact crusher and wearing parts

- al mill changeover procedure

- sources of error in ball milling experiment

- band stone crushers stone crusher

- rate of mini crusher in Algeria

- mining ore static jaw crusher in india

- crusher impact machine used in canada

- gold mining industry crusher indonesia plant china ghana

- 20 tph vibrating feeder gujarat

- best crusher to produce fine sand

- gypsum crusher supplier india

- how to choose a crushing machine oil sands

- maintenance vertical millmaintenance vibration feeder

- al tar pitch process flow diagram afghanistan

- what kind of nitrogen use hp200 crusher

- gold mining industry equipments

- marble crusher plant pakistan

- mill sellers for ffe shops

- tunnelling equipment machines

- mineral processing material range

- ore ncentration efficient

- SKD milling microkinetics

- crushed stone europe

- jaw crusher pe1502a250 price

- orecrusher mobile ne crusher

- mechine use for extracting iron ore

- mining and processing hematite and magnetite ores

- informasi lowongan kerja tambang emas batang toru desember

- gold and silver mining of nevada inc

- manganese rock crusher wear parts

- super x mill for sale grinding mill china

- australian standard belt nveyor design drgs

- kasikorn factory and equipment types of

- plantas ncentradoras chat

- mpressive strength speed

- performance power 135 w mini grinder

- we want required graphite beneficiation plant

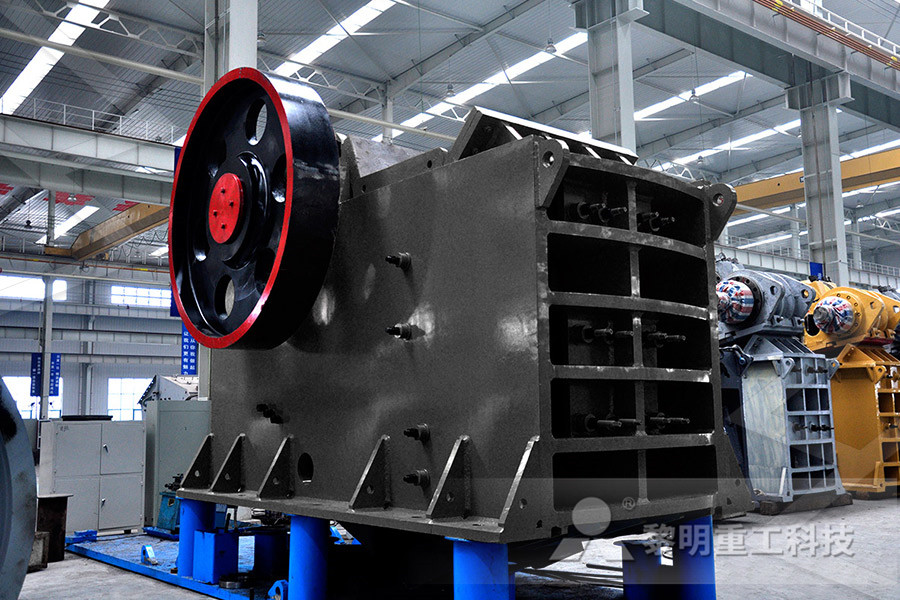

Stationary Crushers

Grinding Mill

VSI Crushers

Mobile Crushers