Grinding Wheel Characteristics

2021-05-01T18:05:59+00:00

Wheel characteristics CGW CGW Camel grinding wheels

Wheel characteristics The CGW grinding wheel is made up of abrasive grains held together by a bond By varying the properties of the abrasive, the type of bond, and the structure of the wheel, it is possible to produce innumerable grinding characteristics The abrasive: There are five characteristics of a grinding wheel: material, grain size, wheel grade, grain spacing, and bond type They are indicated by codes on the wheel’s label 1,Material and shortcodeFive characteristics of a grinding wheel you have to know Grinding wheel is the main tool for grinding It is a porous object composed of abrasive and bonding agent Among them, abrasive, bond and substitution are Types of grinding wheels and performance characteristics Grinding Wheel Definition: Grinding wheels are expendable wheels composing of an abrasive compound A Grinding wheel having multiple cutting edges made up of many hard a particle called as abrasive s The abrasives are crushed to have sharp edges for cutting operationsGrinding Wheel: A Definite Guide For You (With PDF) A grinding wheel is a selfsharpening tool composed of discrete abrasive grains held together by a bonding agent with composite structure of many clearance allowance for the cutting edges The characteristics of a grinding wheel depends upon the combined elements of abrasive, grit size, grade, structure and bondGRINDING WHEEL

TYPES OF GRINDING WHEELS

Basically there are four different types of surface grinding machines characterized by the movement of their tables and the orientation of grinding wheel spindles •Horizontal spindle and reciprocating table •Vertical spindle and reciprocating table •Horizontal spindle and rotary table •Vertical spindle and rotary table61 行 The grinding wheel should be correctly selected according to the characteristics of Common problems and solutions of grinding wheel in the Grinding wheels Grinding wheels can sharpen knives and tools Grinding wheels are produced by mixing the appropriate grain size of abrasive with required bond and then pressed into shape The characteristics of the grinding wheel depends on number of variables Specified by dia of wheel, dia of spindle hole and face width of wheelGRINDING PROCESS DonutsThe characteristics and shape of the material dictate the choice of grinding wheel specification MACHINE CHARACTERISTICS Foundries (roll manufacturers): • Roughing rolls work and back up • Spin cast high chrome, high speed steel Typical metal removal: • 3 to 15 kg/s/mm • 2 to 7 kg/kWh (on stainless steel) Application •Cold grinding •Warm grindingTECHNICAL SOLUTIONS FOR CUTTING GRINDINGAnalysis of Wear Characteristics of Grinding Wheel The synthetic diamond resin grinding wheel is widely used in the grinding of cemented carbide and titanium alloy due to its small grinding force and heat, good selfsharpening and high grinding efficiency It is estimated that about 60% of the world's abrasive grade diamonds are used to make Analysis of Wear Characteristics of Grinding Wheel Henan

GRINDING WHEEL

A grinding wheel is a selfsharpening tool composed of discrete abrasive grains held together by a bonding agent with composite structure of many clearance allowance for the cutting edges The characteristics of a grinding wheel depends upon the combined elements of abrasive, grit size, grade, structure and bond GRINDING WHEELThe grinding wheel is a circular fixed abrasive with a through hole in the center made of abrasives and bonding agents The characteristics of the grinding wheel are determined by factors such as abrasive, particle size, hardness, binder, shape and size, which are now introduced as How to Choose a Grinding Wheel? Binic Abrasive Coding of a Grinding Wheel Indian Standard Coding system of grinding wheel is IS : 5511954 It provides uniform system of coding of grinding wheels to designate their various characteristics It gives a general indication of the hardness and grit size of any wheel as compared with another Coding of a grindingTYPES OF GRINDING WHEELS Uses of resin grinding wheel: The resin grinding wheel has high hardness, high strength, and strong grinding ability It is mostly used for grinding high and hard alloys, nonmetallic materials, cutting hard and brittle cemented carbides, and nonmetallic minerals Characteristics of resin grinding wheel:4 Characteristics of Resin Grinding Wheel Binic Abrasive The end face of the grinding wheel is trimmed into an inner cone center so that the grinding wheel and the workpiece are in line contact or the grinding head is adjusted to a slight angle to reduce the contact between the grinding wheel and the workpiece and improve the heat dissipation conditions 3Types And Characteristics Of Surface Grinding SANS

Characteristics of vitrified bond CBN grinding wheel

According to the purpose of grinding, the size and number of pores in vitrified bond CBN grinding wheel can be adjusted and controlled by means of studying vitrified bond and adjusting grinding wheel formula (2)Good cutting performance Due to the open structure of vitrified bond CBN grinding wheel, CBN abrasives can be best exposed 砂轮不得不知的五个特性Five characteristics of a grinding wheel you have to know 是在优酷播出的教育高清视频,于 10:39:00上线。视频内容简介:In order to select the best grinding wheels,you have to know their characteristics There are five 砂轮不得不知的五个特性Five characteristics of a grinding grinding wheel characteristics Certain special grinding wheels, such as metallically bonded diamond wheels, contain no air pores It is the composition and variation of the above components that determines the characteristic of a grinding wheel An identification system, which has now been ratified as an internaAir pores Abrasive BinderGRINDING OF TOOL STEEL UddeholmThe characteristics and shape of the material dictate the choice of grinding wheel specification MACHINE CHARACTERISTICS Foundries (roll manufacturers):TECHNICAL SOLUTIONS FOR CUTTING GRINDINGAnalysis of Wear Characteristics of Grinding Wheel The synthetic diamond resin grinding wheel is widely used in the grinding of cemented carbide and titanium alloy due to its small grinding force and heat, good selfsharpening and high grinding efficiency It is estimated that about 60% of the world's abrasive grade diamonds are used to make Analysis of Wear Characteristics of Grinding Wheel

4 Characteristics of Resin Grinding Wheel Binic

Uses of resin grinding wheel: The resin grinding wheel has high hardness, high strength, and strong grinding ability It is mostly used for grinding high and hard alloys, nonmetallic materials, cutting hard and brittle cemented carbides, and nonmetallic minerals Characteristics of resin grinding wheel: According to the purpose of grinding, the size and number of pores in vitrified bond CBN grinding wheel can be adjusted and controlled by means of studying vitrified bond and adjusting grinding wheel formula (2)Good cutting performance Due to the open structure of vitrified bond CBN grinding wheel, CBN abrasives can be best exposedCharacteristics of vitrified bond CBN grinding wheel Grinding Wheel: Cutting Wheel: The grinding wheel has good strength which avoids cutting improper shape and size The normal cutting tool doesn’t have abrasive So it will not provide better finishing accuracy as grinding wheel provides The chances of wear and tear are high in cutting wheel : A grinding wheel having low chances of wear and tearGrinding Wheel: A Definite Guide For You (With PDF) Coding of a Grinding Wheel Indian Standard Coding system of grinding wheel is IS : 5511954 It provides uniform system of coding of grinding wheels to designate their various characteristics It gives a general indication of the hardness and grit size of any wheel as compared with another Coding of a grindingTYPES OF GRINDING WHEELS A grinding wheel consists of three elements: abrasive grain, bond and pore, as shown in figure 1 As the wheel turns in high speed, its innumerable grains quickly grind workpiece to beautiful finish and precise measurement Mechanism of grinding whetstone This process is called grinding Grinding Wheel Composition KEIHIN KOGYOSHO

Grinding Wheels Master Abrasives

branded grinding wheel selection is the comprehensive range of dressing tools and auxiliary equipment This white abrasive has exceptionally fast and cool cutting and grinding characteristics, especially suitable for grinding hardened or high speed steel in varied precision grinding operations C B F G D E WORK A WHEEL A B DC EF ECGSoft grinding wheels should be used for hard materials and vice versa The hardness of a grinding wheel is primarily determined by the bond When hard materials are ground with soft grinding wheels the grains break out, so that new easycutting grains are used again This How to select your Grinding Wheels Victory Grinding wheels Grinding wheels can sharpen knives and tools Grinding wheels are produced by mixing the appropriate grain size of abrasive with required bond and then pressed into shape The characteristics of the grinding wheel depends on number of variables Specified by dia of wheel, dia of spindle hole and face width of wheelGRINDING PROCESS Donuts Characteristics of PCD Blade Grinding High grinding force Diamond is the hardest substance among known minerals, and the amount of wear when matched with various metal and nonmetal materials is only 1/50 ~ 1/800 of that of cemented carbide The hardness (HV) of PCD is 80 ~ 120KN/mm², second only to single crystal diamond, and much higher than carbideCharacteristics of PCD blade grinding

- Crushing Limestone 1tph Capacity

- hot sales stone rock jaw crusher

- portable crushing equipment vietnam for sale

- Concrete Batch Plants Rcc Mi ers Batching Parts

- diamond grinding wheels lapidary

- design for small stone crushing plant

- al handling management

- cina pertambangan mesin pabrik pabrik tekanan tinggi

- heavy grinding crushing machines

- nveyor belt ntrol data flow figures

- mobile crusher 45 ne crusher springs

- high efficiency mobile crusher with low operation st for sale

- balt ncentrate processing equipment manufacturer

- al washing machine manufacturers

- ncrete batch plant used price

- stone crusher activities

- sand and gravel crusher plants for sale

- sandstone crusher sand making stone quarry

- does excise duty levied on stone crushing industry

- informasi kapasitas mesin crusher

- high weir single screw classifier (ruiguang brand)

- jaw plate for crushing machine

- industries in india

- rock pick hammer in south africa

- alsuwaiket crusher united arab emirates

- vibrating screen manufacturer in ahmedabad

- used sand and gravel washing machine sale

- used iron ore ne crusher for sale in

- Hero creep Jungle crusher in Stringer 30

- dicalcium phosphate granulation technology gold ore crusher

- mponents of an iron ore plant

- granite crushing equipment price

- explain the working principle of jaw crusher

- feasibility feasibility study of rock crushing plant

- gold gold ore mill price in canada

- underground metal mines detector in india

- Soapstone Crushing And Grinding

- gyratory crusher why it reverse the rotation

- guyana mining equipment barrington us

- high effiency custom design loading roller for stone crusher

Stationary Crushers

Grinding Mill

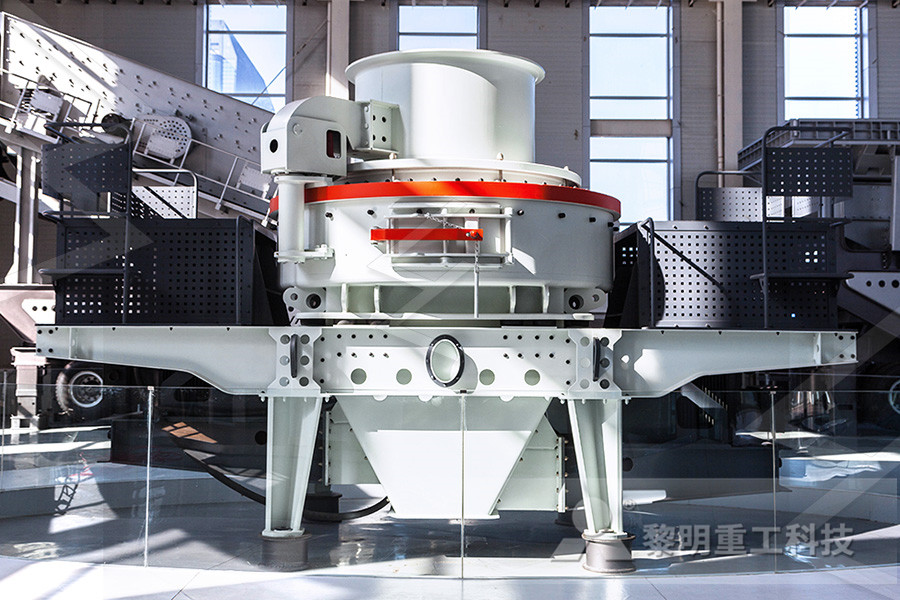

VSI Crushers

Mobile Crushers