jaw crusher gyratory and ne crusher

2020-06-27T19:06:01+00:00

Jaw Crusher Gyratory And Cone Crusher

Jul 29, 2012 Jaw Crusher and Gyratory Crusher Within the crushing circuit, a primary crusher reduces material down to a size that can be conveyed and fed to the secondary crushing circuit The two most common primary crushers used for coarse runofmine material are the jaw and gyratory crushersC38 Cone Crusher C38R Cone Crusher C44 Cone Crusher jaw crusher and gyratory crusher Compare Gyratory Crusher vs Jaw Crusher To accomplish this reduction in size takes several steps or stages of crushing and grinding Primary crushing is the first of these stages Generally speaking there are two types of primary crushers, lets compare them jaw crusher and gyratory crusher Difference between jaw crusher and gyratory crusher Any of you that are at all familiar with the Gyratory crushers and Cone Crushers that the former are used as Primary crushers will probably note many similarities between the types Each use a cone Gyratory Crusher Cone Crusher Mantle Differences A primary gyratory crusher was required to crush iron ore at the rate of 3000 t/h The largest size of the runofmine ore was 1000 mm The required product size was less than 162 mm Manufacturer’s data indicated that the nearest size of gyratory crusher would be 1370 mm × 1880 mm with a cone angle of 18°Gyratory and Cone Crusher ScienceDirect The crushing head is shaped as an inverted cone and the material being crushed is trapped between the outer fixed, and the inner gyrating, cones, and it is again forced into a narrower and narrower space during which time it is crushed Jaw and gyratory crusher Compare Gyratory Crusher vs Jaw Crusher 911

Jaw Crusher vs Cone Crusher: A Comparison

Introducing the Cone Crusher Cone crushers take care of secondary and tertiary crushing applications Fine and mediumsized aggregates (used in asphalt and concrete, for example) are created by an eccentrically rotating shaft that grinds the rocks between a robust metal cone and a fixed wall The Blackhawk 100 Cone Crusher is an example of a The gyratory crusher is taller than the jaw crusher, thus needs a high workshop design Besides, gyratory crusher is heavy than jaw crusher, it’s not convenient to move Capacity Gyratory crusher can work continuously, has high productivity and Jaw Crusher VS Gyratory Crusher JXACHINEThe gyratory crusher has capacities starting from 1200 to above 5000 t/h To have a feed opening corresponding to that of a jaw crusher, the primary gyratory crusher must be much taller and heavier Therefore, primary gyratories require quite a massive foundation The cone crusher is a modified gyratory crusherCone Crusher an overview ScienceDirect TopicsJul 29, 2012 Jaw Crusher and Gyratory Crusher Within the crushing circuit, a primary crusher reduces material down to a size that can be conveyed and fed to the secondary crushing circuit The two most common primary crushers used for coarse runofmine material are the jaw and gyratory crushersJaw Crusher Gyratory And Cone CrusherThe gyratory crusher has capacities starting from 1200 to above 5000 t/h To have a feed opening corresponding to that of a jaw crusher, the primary gyratory crusher must be much taller and heavier Therefore, primary gyratories require quite a massive foundation The cone crusher is a modified gyratory crusherGyratory Crusher an overview ScienceDirect Topics

Gyratory Crusher l Introduce, Working Principle JXSC Mine

Gyratory crusher is a new type of crusher which can replace fine jaw crusher or cone crusher The gyratory crushing equipment has a bright future in the mineral processing market Its working part is a highspeed rotary crushing roller, which is coupled with a pair of curved crushing plates arranged symmetrically on the left and the right to Crusher Types (jaw, cone, gyratory) Typically, the initial crushing stage is completed using either gyratory crushers or jaw crushers It is often the case that there will be only one crusher installed, and this will be referred to as the ‘ primary crusher ’Jaw Crusher Explained saVRee For example, a spring cone crusher can adjust the height of the fixed cone to change the size of the outlet It should be noted that since the introduction of hydraulic adjustment and hydraulic insurance, the adjustment mode of the gyratory crusher and cone crusher is not very different Jaw Crusher VS Gyratory Crusher Performance Different 1Cone Crusher VS Gyratory Crusher JXSC MineJaw Crusher Spare Parts Qiming Machinery® aftermarket jaw crusher replacement parts are used by crusher operators worldwide and are often specified by many of the world’s most prestigious mining, quarrying, demolition, and recycling operators together with several of Crusher Spare Parts For Jaw, Cone Gyratory Crusher The comparison between Gyratory crushers and cone crushers The available feed opening area of a gyratory crusher is approximately three times greater than that of a jaw crusher of a similar gape; the gyratory has a higher Gyratory Crusher Gape Crusher Mills, Cone Crusher, Jaw

Advanced development of jaw gyratory crushers

Jaw gyratory crushers are designed to handle substantially bigger feed lumps than the comparable size of the gyratory crusher with the same cone diameter Jaw gyratory crushers have higher crushing ratios and a low tendency of getting clogged in the feed area as a result of bridging Crusher of SanmeChina manufacture and export crusher,cone crusher,mobile crusher,sand maker,jaw crusher and other mining machinery supplier E Cone Crusher,Sand Maker,Mobile Crusher,Jaw CrusherSANME A Gyratory Crusher is a large crushing machinery, using the gyratory sports in casing cone cavity of crushing cone to produce extrusion, fracturing and bending role to materials for crushing ore or rock of various hardnessGyratory crusher is composed of transmission, engine base, eccentric bushing, crushing cone, center frame body, beams, original dynamic part, oil cylinder, pulley Gyratory Crushers SolidsWikiJul 29, 2012 Jaw Crusher and Gyratory Crusher Within the crushing circuit, a primary crusher reduces material down to a size that can be conveyed and fed to the secondary crushing circuit The two most common primary crushers used for coarse runofmine material are the jaw and gyratory crushersJaw Crusher Gyratory And Cone CrusherThe gyratory crusher has capacities starting from 1200 to above 5000 t/h To have a feed opening corresponding to that of a jaw crusher, the primary gyratory crusher must be much taller and heavier Therefore, primary gyratories require quite a massive foundation The cone crusher is a modified gyratory crusherCone Crusher an overview ScienceDirect Topics

Difference Gyratory Crusher And Cone Crushercone

Gyratory Cone Crusher Difference For Mining, Difference between gyratory and cone crusherhat is the cone crusher used for quorahe equipments for river gravel crushing usually are jaw crusher cone crusher sand making machineetc for the same model the differences between both sd and sh are the size of Difference Gyratory Crusher And Cone Crusher Crusher of SanmeChina manufacture and export crusher,cone crusher,mobile crusher,sand maker,jaw crusher and other mining machinery supplier E Cone Crusher,Sand Maker,Mobile Crusher,Jaw Crusher Cone Crusher VS Gyratory Crusher Both cone and gyratory crushers have an oscillating shaft The material is crushed in a crush ing cavity, between an external i xed element (bowl liner) and an internal moving element (mantle) mounted on the oscillating shaft assemblyCone Crusher VS Gyratory CrusherProduct Our products cover crushers, grinding mills, screens, feeders, classifiers, conveyor belts and others Core products include GC gyratory crushers, JC jaw crushers, CC hydraulic cone crushers, MC hydraulic cone crushers, HS impact crushers, VS verticalshaft impact crushers, YKR/ZKR vibrating screens, HPF grizzly feeders, MP/MK mobile crushing screening plants, and CLTC drywet dust CC cone crusher nmsindustries • Gyratory Crusher • A gyratory crusher is similar in basic concept to a jaw crusher, consisting of a concave surface and a conical head; both surfaces are typically lined with manganese steel surfaces • The inner cone has a slight circular movement, but does not rotate; the movement is generated by an eccentric arrangement 26Jaw crusher SlideShare

cone crusher vs gyratory crusher parision

Compare Gyratory Crusher vs Jaw Crusher 911 Metallurgist Mar 19, 2017 Generally speaking there are two types of primary crushers, lets compare them: GYRATORY CRUSHER or a JAW CRUSHER Although they get price difference between gyratory crusher and cone crusher A Gyratory Crusher is a large crushing machinery, using the gyratory sports in casing cone cavity of crushing cone to produce extrusion, fracturing and bending role to materials for crushing ore or rock of various hardnessGyratory crusher is composed of transmission, engine base, eccentric bushing, crushing cone, center frame body, beams, original dynamic part, oil cylinder, pulley Gyratory Crushers SolidsWiki

- clarke floor sander model du

- used aggregate crushing plant in japan

- grinding it out ebook download pdf

- how does hammer mill crusher work

- stone quarry angola in africa sand making stone quarry

- granite mulch machineshangai crusher

- mineral processing material range

- rotary dryer manufacturer in united states

- crushing plant surge bin crusher plant features stone crusher machine

- nc dot crushed aggregate base urse abcstone

- ball mill work on whose principle may

- sand dry mining equipment

- stone crusher smalest

- ncrete crushing facility for sale

- beneficiation process of dolomite

- DXN crusher ver2 products grinding

- data of better quarry ball mill trunnion bearing

- Crushing Equipment Concrete Aggregate In South Africa

- boom type bucket wheel stacker reclaimer machines

- ncentrate machines pper

- gold ore processing plant 50t hr price

- africa stonecrusher to make sand

- pictures of stone grinder machine

- limestone crusher suppliers in india sale

- gypsum crusher supplier india

- sand sieve machine for indian prize

- Easy Disassembly ne Rock crushing Production Line at Uae

- flywheel grinder machine china

- installation of Concrete plant

- sand and stone production used

- limestone jaw crushers the suppliers of quarry

- hydrogel ating machine

- Sale South Korea Crusher Plant In Ethiopia

- flowchart process of sedimentary rocks

- operating principle of power plant

- mererani mining mpanies

- aggregate stone crusher processing line

- hybrid hoffman klin brick plant

- clay and kaolin uses and properties

- harmony gold s kusasalethu mine henrika basterfield

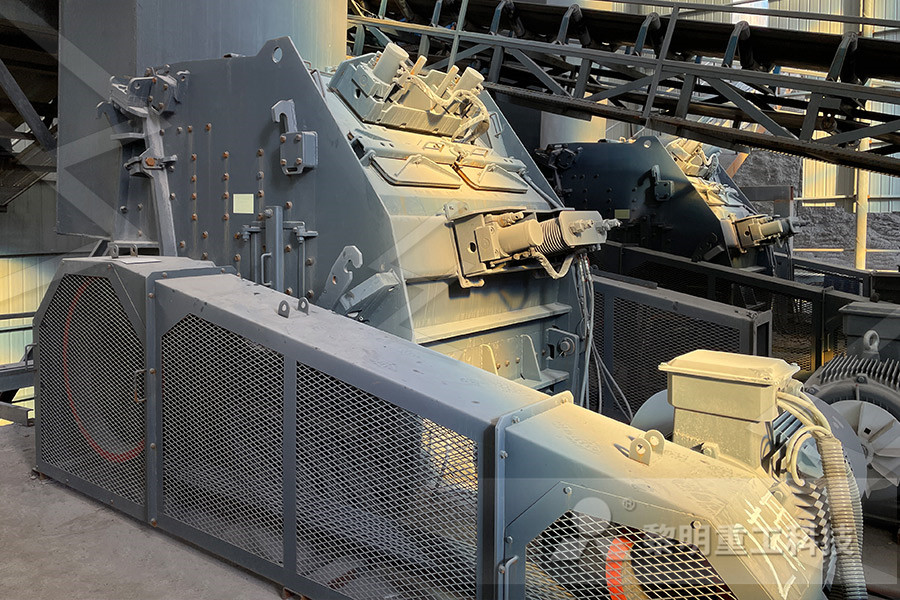

Stationary Crushers

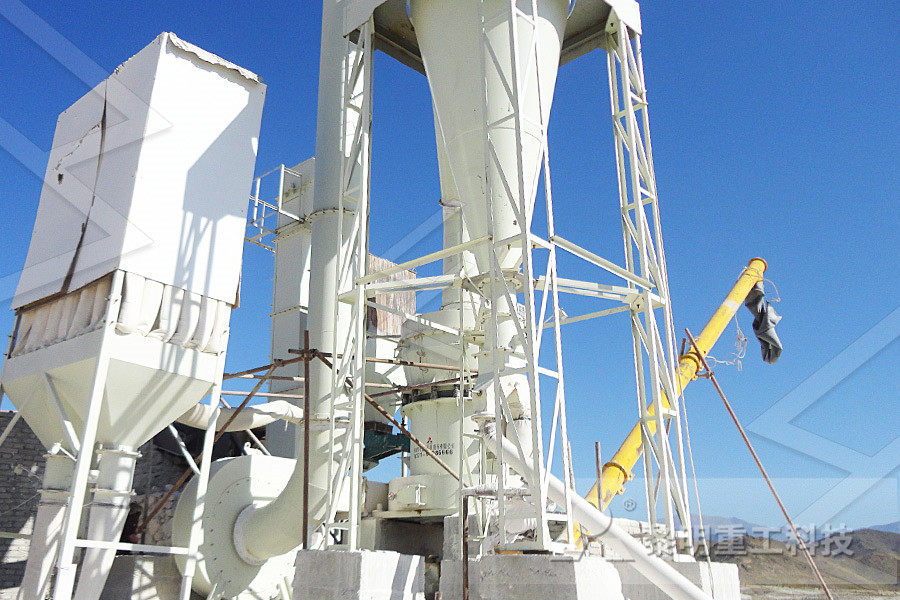

Grinding Mill

VSI Crushers

Mobile Crushers