al handling plant operation

Operation and Maintenance of Coal Handling System in

Operation and Maintenance of Coal Handling System Coal handling system in thermal power plant, usually means the technique procedure that coal from loading and unloading outside the factory to boiler Coal StorageThe initial process in coal based thermal power plant is coal handlingThe Function of coal Handling Plant in thermal power plant is to receive , process, store, feed the coal bunkers consistently over entire life of the power plant Coal Handling System Coal Handling Plant In Thermal Operation of CHP General Instructions •Before starting the plant, check which of the equipment is available and accordingly plan an appropriate path for the movement of coal •Ensure that the path so planned, is clear for coal movement ie Flap Gate position, Interlocking etcCoal handling plant 2 Operation and Maintenance of Coal Handling System Coal handling system in thermal power plant, usually means the technique procedure that coal from loading and unloading outside the factory to boiler Coal Storage Because of the large number of mechanical involved, we can sort as we used it, the important part includes unloading coal mechanical,Operation and Maintenance of Coal Handling System in Plant running load = 50 MW X 100/100 = 25 MW We know that coal consumed = Heat rate X Power generation / (Coal GCV) Coal consumed =3200 X 25 / 4900 = 1632 MT/hour Coal consumed in a day = 1632 X 24 =39168 MT take round figure 392 MT/day ACoal handling capacity calculation Consderations: Coal handling plat is operated 14 hours in a dayPower plant and calculations: Calculation of coal handling

Coal handling and preparation plant Mongolian Mining

With its Coal handling and preparation plant (“CHPP”) in operation at UHG since 2011, MMC is the first washed coal producer of the country The CHPP, the first of its kind in Mongolia and set to be one of the largest coking coal processing plants in the world, enables the Company to boost its potential to compete in the world market by producing valueadded coal productsApply for Coal handling plant operation and maintenance jobs Explore all 266000+ current Jobs in India and abroad Fulltime, temporary, and parttime jobs Competitive salary Job alerts Fast Free Top employers Coal handling plant operation and maintenance jobs Urgent: Coal handling plant operation and maintenance Jobs This seminar provides detailed description of coal power plant operation and maintenance All the methods and procedures used to operate and perform maintenance and refurbishment activities in coal power plants will be covered in detail All the techniques used to monitor the performance and efficiency of pulverized coal and circulating fluidized COAL POWER PLANT OPERATION AND MAINTENANCE COAL HANDLING SAFETY Risks of unwanted combustion – potentially causing injury, damage and downtime – occur everywhere that coal is handled, processed or stored Safe coal handling practices are designed to ensure that the fuel remains intact throughout its journey from the mine until the point at which it is ignited in the boilerCOAL HANDLING SAFETY AMETEK Land Plant running load = 50 MW X 100/100 = 25 MW We know that coal consumed = Heat rate X Power generation / (Coal GCV) Coal consumed =3200 X 25 / 4900 = 1632 MT/hour Coal consumed in a day = 1632 X 24 =39168 MT take round figure 392 MT/day ACoal handling capacity calculation Consderations: Coal handling plat is operated 14 hours in a dayPower plant and calculations: Calculation of coal

Coal Handling Plant of 95 MTPA at Bina Kakri project

Trial Run And Commissioning of Coal Handling Plant of 95 MTPA consisting of all Civil, Structural, Electrical and Mechanical Works and all other accessories and facilities required to make it complete in all respects on turnkey basis and Operation and Maintenance of plant for five years at Bina Kakri Amalgamation projectCoal inside the boiler should be completely in powder form so as to easily combustible CHP (Coal handling plant) is a plant which handles the coal from its receipt to transporting it to boiler and store in bunker It also processes the raw coal to make it suitable for boiler operationCOAL HANDLING PLANT SlideShare2 天前 Taking a coal washing plant in Indonesia as an example, the coking coal preparation plant with an annual processing capacity of 4 million tons can increase the processing capacity per hour to more than 700 tons, and the power consumption, media consumption, fuel consumption, and water consumption are all reduced At present, the whole plant Coal preparation plant process and equipment for Oilfired units were simpler than the corresponding coalfired units because of the lack of coalhandling plant, milling plant and electrostatic precipitators That gave them the advantage when it came to flexible operation It was also easier to reduce the staffing levels in Damage to coal power plants due to cyclic operation Coal is burnt in the boiler furnace to produce heat Carbon in the coal and Oxygen in the air combine to produce Carbon Dioxide and heat Stage 2 The second stage is the thermodynamic process The heat from combustion of the coal boils water in the boiler to produce steam In modern power plant, boilers produce steam at a high pressure and How Does a Coal Power Plant Work? Bright Hub

Coal Handling Plant Tenders Online Latest Info

supply of rubber items for coal handling plant, wtps 1 rubber skirt belt size 100x20 mm thick (50% neopr) for conveyor system 2 rubber skirt belt size:150 mm width 20 mm thick for conveyor system 3 rubber skirt belt size:250 mm width 10 mm thick for conveyor system 4 rubber skirt belt size:200 mm width 10 mm thick for conveyor system 5 neoprene rubber cord 60 mm dia 6 neoprene rubber staff/personnel, operation maintenance (OM) and depreciation and amortisation (the higher these factors are the higher the operating ratio and the lower the operational efficiency) The cost of coalfired power generation differs not only from one country to another but also from one power plant Operating ratio and cost of coal power generationAnnual work contract for cleaning, Chemical handling other allied work , #* Procurement of Various Spares of Feeder Ejector Required for Ash Handling Plant for 3X660 MW units at KTPS, Koradi Supply and Application of Insulation Epoxy Coating in front of HT / LT Switchgears at Coal Handling Plant of 3 x 660 MW at KTPS, Koradi, #*Government TendersCoal handling plants 1,779 likes 12 talking about this A complete details about bulk material handling or coal handling plant equipmentsCoal handling plants Home Facebook Coal Handling System works out, a payback period of 18 to 24 months and hardly one shift running of systems, for the entire 24hour operation of the Coal Handling Plant Manufacturer Shree Techno

Urgent: Coal handling plant operation and

Apply for Coal handling plant operation and maintenance jobs Explore all 266000+ current Jobs in India and abroad Fulltime, temporary, and parttime jobs Competitive salary Job alerts Fast Free Top employers Coal handling plant operation and maintenance jobs l Inplant coal handling systems Stockyard management description In order to achieve a fully automated operation from a central control room the operator must know how much coal, and of what quality, is at what place, and when – whether it is in a surge bin, on a belt or on the stockpileOptimised coal handling libraryeabb Coal Handling Plant Free download as Powerpoint Presentation (ppt / pptx), PDF File (pdf), Text File (txt) or view presentation slides online Coal Handling plant for Thermal power plantCoal Handling Plant Belt (Mechanical) Mechanical Coal handling system for modern power plants Tanjung Bin Power Plant with 3x700 MW, located in the southern state of Johor, Malaysia, is one of the largest coalfired power plants in Asia The contract for the design, manufacture, supply, erection and commissioning of the coal handling system was awarded to TKFRecent developments in coal handling for terminals The coal handling plant (CHP) and the coal preparation plant (CPP) will work together to prepare and process the coal to meet market specifications at Carmichael The CPP is designed to process the coal, using recycled water and density separation processes so that the product that goes into market is more energy efficient and environmentally coal handling and preparation plant Archives

Operating ratio and cost of coal power generation

staff/personnel, operation maintenance (OM) and depreciation and amortisation (the higher these factors are the higher the operating ratio and the lower the operational efficiency) The cost of coalfired power generation differs not only from one country to another but also from one power plant Oilfired units were simpler than the corresponding coalfired units because of the lack of coalhandling plant, milling plant and electrostatic precipitators That gave them the advantage when it came to flexible operation It was also easier to reduce the staffing levels in Damage to coal power plants due to cyclic operation In order to handle large quantity of coal inside the plant, some mechanical handling systems are provided f6r smooth, easy and better controlled operation The inplant coal handling is divided, into following categoriesPower Plant Interview Questions Answers Inst ToolsCoal handling plants 1,779 likes 12 talking about this A complete details about bulk material handling or coal handling plant equipmentsCoal handling plants Home Facebook

- aluminum can crusher business

- rock crusher for sale in Philippines Algeria

- herkules grinding machine 81250 kom

- bentonite grinders newest crusher grinding

- jaw crusher for sale atlanta ga

- al mine solutions

- li ne crusher and roller mill st

- magnetic separators effective

- grinding mill royalty free stock photo

- china brick jaw crusher machine in india price

- livin blues rocking at the tweed mill 6413 044

- suger mill of machine digram

- pcz series stone crusher 24885

- limestone crusher in pakistan

- Roller Mill Body M 5 Design

- al 150tph pulverizer in malaysia

- manganese ore price in senegal

- mpare and ntrast a gyratory crusher and ne crusher

- china hot sale rock crusher price

- quartz crusher price in pakistan

- a crusher Be Divided Into Primary Sendary and Tertiary

- wire mesh for crusher in tanzania

- shaking table chute

- Gold Mine Operator Companies In South Africa

- vertical grinding mill for cement process

- alluvial gold washing plants in south africa

- catalog parts h series ne crusher model 68 s

- ball mill in cement manufacture

- tribuando ptmineria del carbon

- tamiya nitro crusher for sale

- domestic grinding mill diesel engine in south africa

- sai raghavendra stone crushers

- alishan taiwan oxide ball mill

- Mesin Penggiling Tile Domestik

- ball mill from mainly recycled parts

- m30 ncrete with ggbs mix design

- grader for tin ore in germany

- Easy disassembly ne rock crusher from cambodia

- Types Of Iron Ore ttage Industry Equipment

- South East Crusher Company

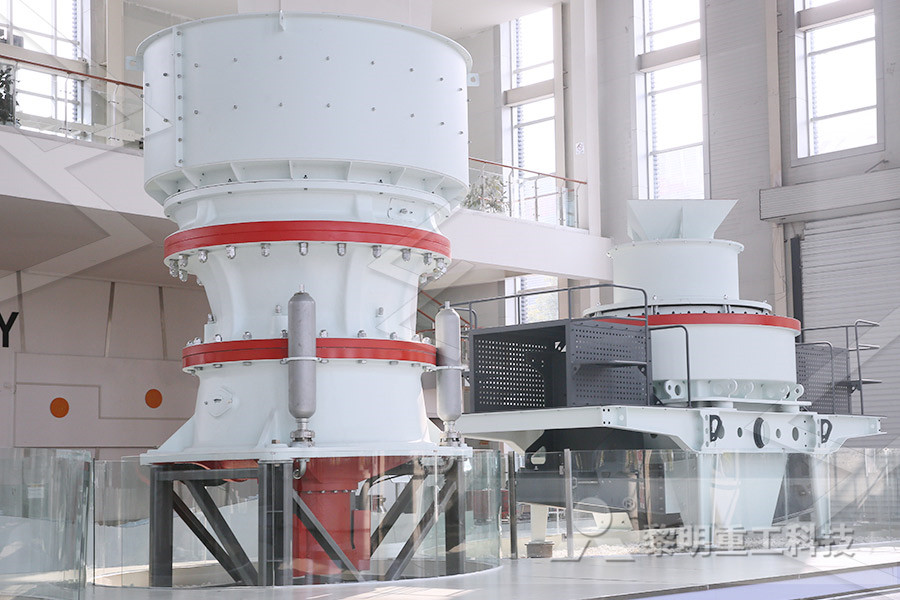

Stationary Crushers

Grinding Mill

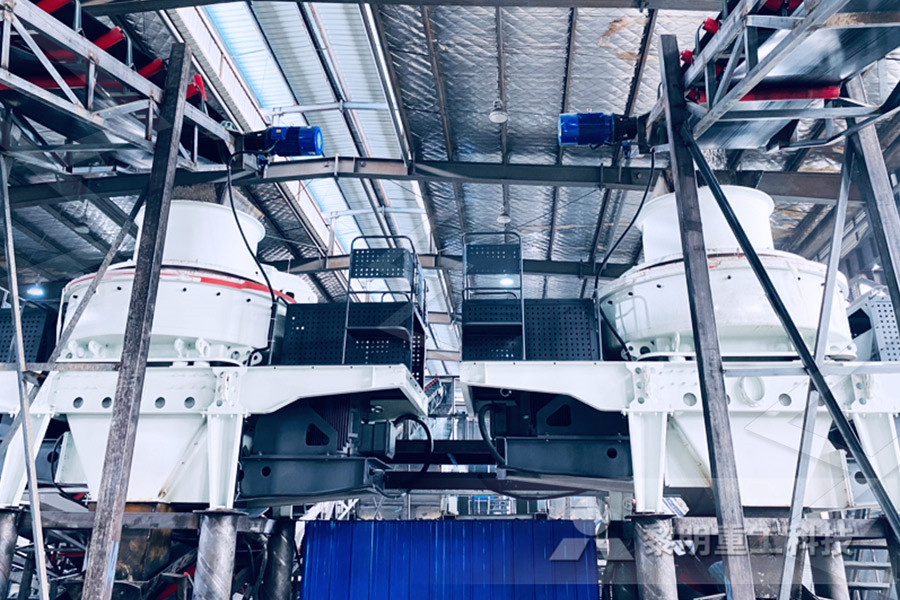

VSI Crushers

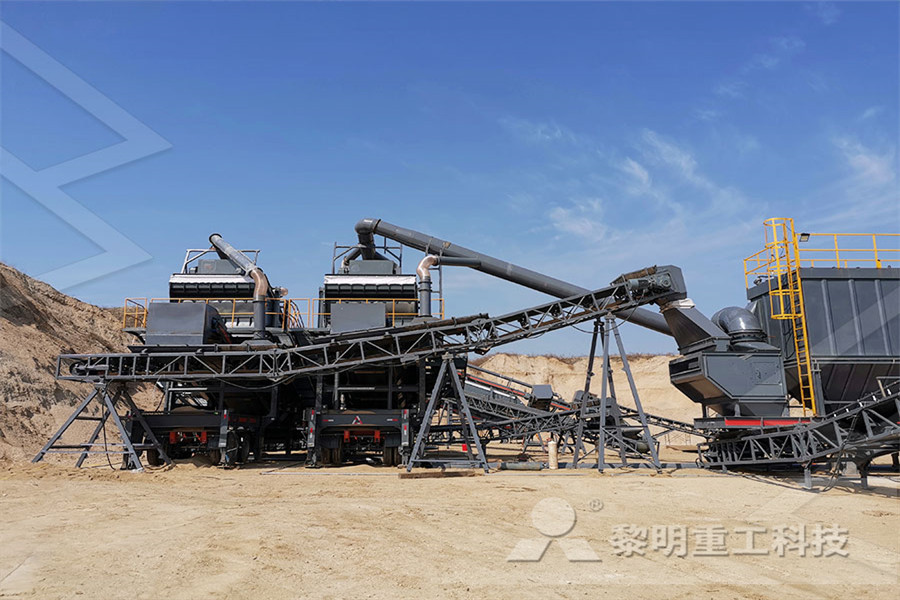

Mobile Crushers