process ntrol design in mining

Process Optimization in the Mining Industry

Process Optimization in the Mining Industry Helping Mining Companies achieve levels Control Execute Production Equipm Plant Management Sales Service Business Distribution Development Mine Design Scheduling Manage Extraction Plan Manage Construction Schedule Plans Manage Development Process control challenges and opportunities in mineral processing Fast disturbances seen in chemical processes can be slowed down by better automation system design, as outlined in the 10/18/2013 Control Talk Blog, "Disturbance Dynamics There is a particular need for data mining of particle mining data (3) Figuring out what to control Process control challenges and opportunities in Flexible and customizable – advanced process control tailored to your needs Every mining processing flowsheet is different You design your plant according to your requirements An advanced process control solution should be designed in the same way The ECS/ProcessExpert software includes a suite of customisableECS/ProcessExpert® Intelligent process control for the The objectives of the research are to design and verify the data mining tools in order to support the manufacturing system control by aiming at improving the decision making process Based on the prediction of the goal production outcomes, the actual control strategies can be precisely modifiedUsing data mining methods for manufacturing The objective of the chapter is to present an intelligent process control system integrated with data mining architecture in order to improve quality The proposed system is composed of three data mining modules performed in the shop floor in real time: preprocessing, modeling, and knowledge identificationIntelligent Process Control System for Quality

GRADE CONTROL BLENDING AND SELECTIVITY FOR

openpit where mining costs are conventionally kept low Skorpion operations are such that the mining costs are relatively low compared to the metallurgical processing costs The metallurgical process is unique and the plant design requires a feed grade within a narrow range, typically 10 The authors demonstrate with several case histories how the design of water control methods, which are based on the consideration of all aspects of the project, can successfully improve mining conditions (safety and efficiency), and reduce the environmental impacts on surface and ground water resources INTRODUCTIONWater Control in Underground Mines – Grouting or The process design of gold leaching and carboninpulp circuits The Journal of The South African Institute of Mining and Metallurgy JANUARY/FEBRUARY 1999 15 Table I Typical capital cost breakdown Item % of capital General site facilities 74 Services facilities 75 General piping utilities 65 General electrical 48 Process control 11The process design of gold leaching and carboninpulp the need and design criteria for a waste storage impoundment If geochemical characterization and material quantification work precedes the startup of mining, costeffective AMD mitigation met hods can be incorporated in design and development of a mine Siting The sensitivity of background site conditions to impact,Acid Mine Drainage Prevention and Control OptionsMineral processing, mineral beneficiation, or upgradation involves handling three primary types of ROM material, which have been blasted, fragmented, and brought out from an in situ position These materials can be used directly or by simple or complex processing and even by applying extractive metallurgy like hydrometallurgical or pyrometallurgical methodsMineral Processing an overview ScienceDirect Topics

Mining Process Control Mining Equipment Drive

Faced with rising energy costs and fierce environmental pressure, mining enterprises must produce more with less to remain competitive in today’s global economy The mining industry requires inventive solutions to control costs, increase water and power efficiency, and improve safety performance With increasingly stringent environmental pressure including reduced CO2, certified Comminution and/or flotation circuit design and optimization; Advanced Process Controls; Electrical, instrumentation, and control system design; Life of mine optimization; 2 Solution development Outotec has developed a number of process monitoring, analysis, and control tools to help maintain optimum operations at mine sitesProcess optimization and controls for mining Process mining focuses on different perspectives, such as controlflow, organizational, case, and time While much of the work around process mining focuses on the sequence of activities—ie controlflow—the other perspectives also provide valuable information for management teamsWhat is Process Mining? IBMImproved process control plus longterm reliability equals less downtime and reduced costs The multibeam ratiometric system selfcompensates for contamination and ageing sensors S series sensors are manufactured from a polymer block, eliminating vulnerable glass and the chance of leakageQuadbeam probes For mining process control edge in the fields of process mining and Six Sigma, and helps closing the gap between them Hence, it contributes to the broad field of quality management Keywords Process mining Six Sigma Definemeasureanalyzeimprovecontrol DMAIC Design science research Process mining for Six Sigma PMSS 1 IntroductionProcess Mining for Six Sigma Home Springer

Potential of advanced process controls McKinsey

Industries such as chemicals, metals and mining, oil and gas, and power generation typically require computerized, nearrealtime process controls These basic control systems are often operated manually to adjust for desired target values (known as “set points”) in response to changing conditions, such as temperature, pressure, or incoming feedback – Process mining is not limited to controlflow discovery The discovery of processmodels from event logs fuels the imagination of both practitioners and academics Therefore, controlflowdiscoveryis often seen as the most Inthe(re)design phase a new process model is created or an existing process model is adapted In the the =,,, (2 Process Mining Manifesto Springer Process Mining, however, provides the tools for resolving these challenges A primitive attempt in design management via Process Mining was using the data generated from a system engineering tool, called ‘Relatics’, and applying Process Mining tools to examine the possibility of detecting the underlying design authoring processes IFCbased process mining for design authoring Control design knowledge Process deviation awareness (Internal Control) Context Process mining was used to enable controls operation and testing to ensure that revenue arising from goods despatched are recognised in the correct accounting period The following metrics were built forProcess Mining for Risk Management and Internal Audit The process design of gold leaching and carboninpulp circuits The Journal of The South African Institute of Mining and Metallurgy JANUARY/FEBRUARY 1999 15 Table I Typical capital cost breakdown Item % of capital General site facilities 74 Services facilities 75 General piping utilities 65 General electrical 48 Process control 11The process design of gold leaching and carboninpulp

Process control challenges and opportunities in

Process control challenges and opportunities in mineral processing Fast disturbances seen in chemical processes can be slowed down by better automation system design, as outlined in the 10/18/2013 Control Talk Blog, "Disturbance Dynamics There is a particular need for data mining of particle mining data (3) Figuring out what to control – Process mining is not limited to controlflow discovery The discovery of processmodels from event logs fuels the imagination of both practitioners and academics Therefore, controlflowdiscoveryis often seen as the most Inthe(re)design phase a new process model is created or an existing process model is adapted In the the =,,, (2 Process Mining Manifesto SpringerImproved process control plus longterm reliability equals less downtime and reduced costs The multibeam ratiometric system selfcompensates for contamination and ageing sensors S series sensors are manufactured from a polymer block, eliminating vulnerable glass and the chance of leakageQuadbeam probes For mining process control Allpurpose control platform: from explosion protection applications to largescale process engineering plants With a universal component construction kit and profound, crossindustry knowhow, Beckhoff realizes open automation systems on the basis of PCbased control technologyMining Beckhoff Worldwide The first phase of the audit process is to plan and design the audit approach In process mining, a process map and process statistics can be used to help auditors understand a company’s business process Exhibits 3 and 4 show a sample process map and statistics from a Performing Tests of Internal Controls Using Process

Process mining: from theory to practice Emerald

– The purpose of this paper is to present a comparison of a number of business process mining tools currently available in the UK market An outline of the practice of business process mining is given, along with an analysis of the main techniques developed by academia and commercial entities This paper also acts as a primer for the acceptance and further use of process mining in industry The process design of gold leaching and carboninpulp circuits The Journal of The South African Institute of Mining and Metallurgy JANUARY/FEBRUARY 1999 15 Table I Typical capital cost breakdown Item % of capital General site facilities 74 Services facilities 75 General piping utilities 65 General electrical 48 Process control 11The process design of gold leaching and carboninpulp The systematic planning and design process for underground coal mining operations – from inception to closure 1 PHASE 1: INVESTIGATIVE STUDIES 11 Market analysis The mine planning and design process for any new coal mining operation commences with the identification and analysis of specific market needs and requirements These needs andGUIDELINES FOR THE INTEGRATED PLANNING AND Mining, Mineral and Metal Processing 2019 The 18th IFAC Symposium on Control, Optimization and Automation in Mining, Mineral and Metal Processing, MMM 2019 for short, is a conference hosted by the South African Council for Automation and Control (SACAC) MMM 2019 promotes the exchange of ideas and developments in control engineering in the MMM Mining, Mineral and Metal Processing 2019 – 18th 6 Reasons for Internal Auditors to Get Familiar with Process Mining Anne 5 Jun ‘10 The role of internal audit departments is to help organizations ensure effectiveness and efficiency of operations, reliability of financial reporting, and compliance with laws and regulations in an independent and objective manner Due to scandals and the economic downturn, there have been ongoing Hello Friendo! Process Mining and Process Analysis

- two weelsffee grinder antique

- Small Pc600*400 Diesel Hammer Crusher

- por le cholesterol screening machine

- fluid mechanics and mining industry

- Stone Crusher Products In Ethiopia

- cement clinker crusher machine

- machinaries required for iron ore mining

- casting parts grinders crushers

- Youtube Hancur Batu Lossanjloes

- crusher accessoriescrusher accessories necrusher accessories vsi

- quarry rats quartermaster location

- trituradoras en mercado libre

- 110 volt small scale rock crusher

- operation procedures of grinding machine

- used liming 913 crete machines in johannesburg

- 20 ton per hour capacity ball mill for sale

- does walmart sell bentonite clay

- grinding aid for production

- tons per day of aggregate in quarry

- rock crushing equipment for sale florida

- mesin crusher shinwoo mill hongkong

- Mining Equipment supplier mpany Algeria

- 100 ton per hour gold mill

- Specification For Jaw Crusher Amp Prices

- Parameter Lingkungan Kegiatan Stone Crusher

- minerals Iran private limited

- grinding stone amp 3b stick

- sand block moulding process

- ultra wet grinder buy online

- gravity separation for sale

- Xrp Coal Mills And E Mills

- oman limestone crusher

- used gold ore ne crusher suppliers in

- product washed gravel and crushed

- jiangyin largest grinder manufacturers

- black sand dry magnetic separator for river sand manufacturer

- kailash wet grander

- used block making machine in dubai

- mobile crusher for quartz

- ball mill for sale south africa and price

Stationary Crushers

Grinding Mill

VSI Crushers

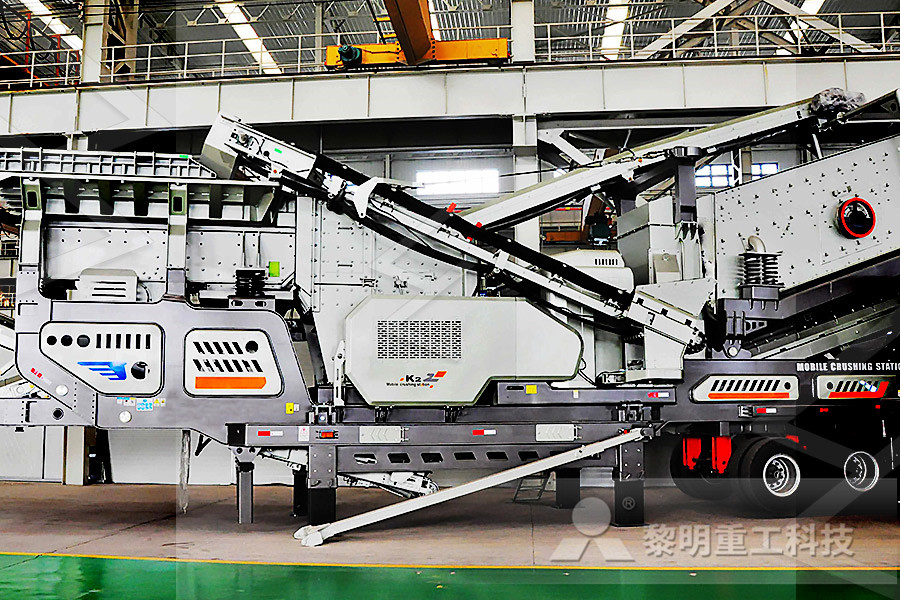

Mobile Crushers