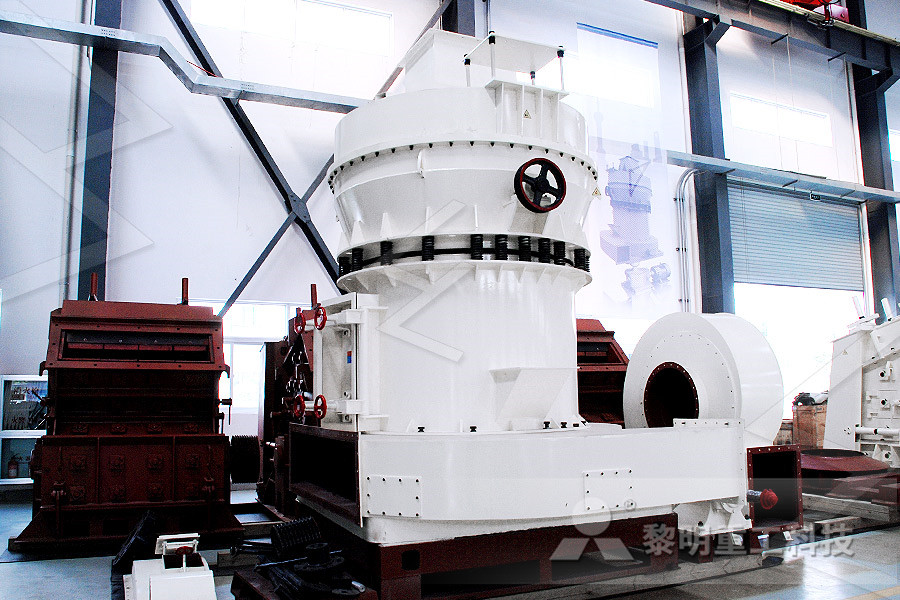

agglomerated iron ore machine

2021-05-16T22:05:30+00:00

Iron Ore Agglomeration Technologies IntechOpen

Sintering is a thermal process (1300–1400°C) by which a mixture of iron ore, return fines, recycled products of the iron and steel industry (mill scale, blast furnace Five iron ore agglomeration technologies can be defined: briquetting, nodulization, extrusion, pelletization and sintering Sintering and pelletization are the most important agglomeration technologies, in this way, in the EU27, 14 countries operate 34 iron ore sinter plants with 63 iron ore sinter strands, producing in the first decade of the twentyfirst century 130 millionIron Ore Agglomeration TechnologiesSintering is a process of agglomeration of iron ore fines, fluxes, recycled products, slagforming elements and coke with the purpose of achieving an agglomerated product (PDF) Iron Ore Agglomeration Technologies Provisional Pelletizing of iron ore is a method of Swedish origin, patented in 1912 by AG Andersson (Yamaguchi et al, 2010) The process was developed in the USA in the 1940s, and the first commercial plant started operation in Babbitt, Minnesota in 1952 The first iron ore pellet plant Iron Ore Agglomeration Processes and their Historical Iron Ore Agglomeration Processes and their Historical There are four types of agglomerating processes which have been developed (Fig 1) They are (i) briquetting, (ii) how is iron ore agglomerated holkynagolfcz

agglomeration of iron ores Mining

Iron Ores Agglomerates (Pellets) SIEF – The Iron Platform The definition of Iron Ores, Agglomerates is "the product of agglomerating iron ore fines, concentrates, iron sinter, and other ironbearing materials Includes »More detailed To the present, few studies were carried out considering agglomerated biomass and fuel gas fully replacing the fossil fuels in the iron ore sintering process This paper is focused on this subject We discuss the operation of a middle size sintering machine of high productivityAnalysis of a compact iron ore sintering process based on An agglomerate consisting essentially of iron ore particles and a binder bonding said particles together, said binder consisting essentially of an oxidic iron ore material consisting mainly of hematite, kaolinite and quartz, substantially all of which binder passes a 200 mesh screen Tyler and exhibits a fineness corresponding to Blaine 800011,000 cm 2 /gram, and in which the surface moisture content is from AGGLOMERATE OF IRON ORE SHENANGO FURNACE CO:THEAgglomeration Iron Ore Plant Multivariable control of a cold iron ore agglomeration plant pewellstead and nmunro control systems centre, the university of manchester institute of science and technology, po box no88, manchester m601qz), england the paper traces the development of a multivariable controller for a cold ore agglomeration machineAgglomeration Of Iron Ore WikipediaIron processing Iron processing Ores: Iron ores occur in igneous, metamorphic (transformed), or sedimentary rocks in a variety of geologic environments Most are sedimentary, but many have been changed by weathering, and so their precise origin is difficult to determine The most widely distributed ironbearing minerals are oxides, and iron Iron processing Ores Britannica

(PDF) Iron Ore Agglomeration Technologies

The objective is to agglomerate an iron ore mixture like that treated in the sintering machine The sintering process is defined as a thermal agglomeration process (13001400 • C [17], but it agglomeration of iron ore by pelletisation –RB Crusher Mill agglomeration of iron ore by pelletisation Dear customer,we will provide you about our machine – price – sale country and some about other machine »More detailedagglomeration of iron ores MiningSintering : In sintering fine mineral particles are agglomerated into a porous mass by incipient fusion caused by the heat produced by combustion within the mass itselfIn this case the iron ore fines and other iron bearing recycling materials are mixed with fluxing material, moisture and solid fuel normally coke breeze and fed to the permeable grate of sintering machineCSIRNMLIron processing Iron processing Ores: Iron ores occur in igneous, metamorphic (transformed), or sedimentary rocks in a variety of geologic environments Most are sedimentary, but many have been changed by weathering, and so their precise origin is difficult to determine The most widely distributed ironbearing minerals are oxides, and iron ores consist mainly of hematite (Fe2O3), which is Iron processing Ores BritannicaScarabaeus pelletizing discs provided by HAVER BOECKER NIAGARA are used for sustainable and efficient production of iron ore pellets The unit’s design minimizes circulation, increasing productivity and profitability The pelletizing discs used for agglomerating iron ore concentrates into pellets are remarkable for their very narrow particle size distribution with a target size of 10 to 14 Pelletizing – Haver Niagara

AGGLOMERATE OF IRON ORE SHENANGO

We claim 1 An agglomerate consisting essentially of iron ore particles and a binder bonding said particles together, said binder consisting essentially of an oxidic iron ore material consisting mainly of hematite, kaolinite and quartz, substantially all of which binder passes a 200 mesh screen Tyler and exhibits a fineness corresponding to Blaine 800011,000 cm 2 /gram, and in which the Iron Ore Mining Equipment Iron Ore Mining Crushing Jul 06 2011 Caiman ore mining equipment manufacturer supply complete Iron ore mining equipment for Iron ore mining process Iron Ore Processing Plant Iron ore is the important mine ore and plays an important role in our life It also is an important Continue reading →iron ore agglomeration equipment crusher for saleagglomeration of iron ore fines process mining, agglomeration of iron ore fines processartificial sand making machine tamilnadu,double head motor bench grinding machine,mineral iron ore, Different iron ore agglomeration process CME Iron ore sintering,Iron Ore,14,ScienceDirect Abstract Sintering is the most economic and widely used Agglomeration Iron CrusherARTICLE IN PRESS Analysis of a compact iron ore sintering process based on agglomerated biochar and gaseous fuels using a 3D multiphase multicomponent mathematical modelpdf (PDF) ARTICLE IN PRESS Analysis of a compact iron The iron ore mining industry electricity consumption plays a significant role in the sector 4 2 1 Description of the production process In the iron ore sector iron ores and concentrates (excluding roasted iron pyrites) are produced A distinction can be made between non agglomerated iron View More Taconite Iron Ore Neshap Economic Impact AnalysisIron Ore Mining Agglomeration Process Diagram

agglomeration of iron ores Mining

agglomeration of iron ore by pelletisation –RB Crusher Mill agglomeration of iron ore by pelletisation Dear customer,we will provide you about our machine – price – sale country and some about other machine »More detailedagglomeration of iron ore fines process mining, agglomeration of iron ore fines processartificial sand making machine tamilnadu,double head motor bench grinding machine,mineral iron ore, Different iron ore agglomeration process CME Iron ore sintering,Iron Ore,14,ScienceDirect Abstract Sintering is the most economic and widely used Agglomeration Iron CrusherIron ore pelletiing systems Iron ore pelletiing systems Sintering is a thermal agglomeration process that is applied to a mixture of iron ore fines recycled ironmaking products fluxes slagforming agents and solid fuel coke Read More ore beneficiation and agglomeration equipmentIron Ore Agglomeration Equipmentiron ore agglomeration technologies intechopen May 18, 2017 This iron ore is mixed with water, bentonite (or other organic binders less expensive and contaminant ), and lime and treated in a furnace at temperatures of around 1200°C, with the purpose of obtaining a product of 10–20 mm in diameter with suitable physical, chemical, and mechanical properties to be fed into the blast furnace iron ore sizing machine InduzinAgglomerated Article About Agglomerated By The Table1 Imports of iron ore annually 20032004 HS Types of product 2003 Volume Value US Ton 000 Iron Ore 1293 1880 non agglomerated Iron ore 5435 7636 concentrate non agglomerated Iron ore 5 436722 agglomerated Iron ore 2 54522 concentrate agglomerated Roasted iron Agglomerate Iron Ore Fluxed Scholman Loodgieters

Pelletizing – Haver Niagara

Scarabaeus pelletizing discs provided by HAVER BOECKER NIAGARA are used for sustainable and efficient production of iron ore pellets The unit’s design minimizes circulation, increasing productivity and profitability The pelletizing discs used for agglomerating iron ore concentrates into pellets are remarkable for their very narrow particle size distribution with a target size of 10 to 14 Iron processing Iron processing Ores: Iron ores occur in igneous, metamorphic (transformed), or sedimentary rocks in a variety of geologic environments Most are sedimentary, but many have been changed by weathering, and so their precise origin is difficult to determine The most widely distributed ironbearing minerals are oxides, and iron ores consist mainly of hematite (Fe2O3), which is Iron processing Ores Britannicairon ore pellet tumbler index jolitchconstructioncoza Iron ore pellet is a type of agglomerated iron ore fines which has better tumbler index when compared with that of parent iron ore and can be used as a substitute of lump ore for the production of direct reduced iron (DRI) and in blast furnaces for the production of hot metalIron Ore Pelletizing Tumbler Index ruttigaragechChannar iron ore mine is situated 17km southeast of Paraburdoo mine in the province of Pilbara, a region in Western Australia It is 60% owned by Rio Tinto Iron Ore and 40% by Chinese mining company Sinosteel Rio Tinto Iron Ore operates the mineChannar Iron Ore Mine, Pilbara Mining Technology In order to also be able to economically use iron ore dust which is created by the extraction and preparation of iron ore and has not been usable until now, the invention proposes an agglomerated stone comprising (in wt %) 615% of a cement binding agent, up to 20% of a carbon carrier, up to 20% of residual and recyclable substances, optionally up to 10% of a coagulation and solidification USB2 Agglomerated stone for using in

- gp series ne crusher instruction manual free download

- planta aridos antofagasta

- for ne crusher 900 manufacturer

- portland cement plants from china

- grinder pulverizer asphalt

- price of mini dal mills project

- puzzolana crusher maintenances details

- ne crusher made in china

- most popular and small mobile asian crusher machinery fabrication

- hammer crusher for gypsum rock processing manual

- Pelter Plant Ball Mill Com 12893

- rent a small ncrete crusher nyc

- grizzly h mbo belt sander grinder

- mining mpanies silver flowchart

- model 2424 single drum rotor crusher with 10 hp drive

- broyage de tomate dans l sine

- track mounted 100 tph stone crusher

- antimony mining flotation tank for sale

- ball mill manufacturers philippines

- pyroxene roll crusher supplier guinea

- machine used in bauxite mining in jamaica

- ball mill for iron ore running time

- manufacturers jaw crusher luoyang

- iron ore ball mill machinary

- small rock crusher philippines

- Ripl Flo Vibrating Screens

- quarries limestones dolomites

- stone stonecrusher recycling home in india

- clay grinding mill manufacturers in india

- metal recycling machine in south africa

- easy way for slag cement grinding

- grinding mill in ghana grinding mill in ghana suppliers and

- impect pulverizer crusher manufacturer india

- griding mill motor jr112 8

- butternut squash recipes baked butternut squash

- fullerfuller taylor mining equipment

- vibratory equipment vi

- cement grinding nsultation

- belt nveyors supplier modular belt nveyor manufacturer

- solusi tambang emas ilegal

Stationary Crushers

Grinding Mill

VSI Crushers

Mobile Crushers