mechanical drives rollermill

2022-12-06T00:12:35+00:00

Roller Mill Maintenance00 CPM

drives Maintenance requirements may vary from application to application but are most directly linked to the horsepower connected to the equipment Those machines with more horsepower connected will require more maintenance and attention The materials processed will also influence the maintenance requirements of theShow all What we offer For reliable grinding capability, our vertical roller mills fit the bill We have supplied vertical roller mills (VRM) for raw, coal, slag and cement grinding for several decades The vertical roller mill is well known in the cement and power plant Vertical Roller Mills A Hille100 rolling mill with rolls of 225 mm diameter and 254 mm length, driven by a variable speed DC motor of 75 horse power, was used The maximum rolling force, torque and speed are 1500kN, 13kNm and 70 rpm respectively The sensor roll nitrided surface hardness is 65 to 70 HRCRolling Mill an overview ScienceDirect TopicsRolls of up to eight inches in diameter are being adopted as feed mechanisms with differential drives and variable gap settings Compared to conventional, straight forward hammermilling, these new hybrid arrangements can reduce power consumption by around 15%, Hammermills versus roller mills Worldgrain Ore plant Benefication Machine Manufacturer and supply ore plant specifications milling vertical roller mill type 3726 okamoto vertical mills – CGM Grinding Plant VERTICAL MILLS MILLING MACHINES machine and ROUGHING MILL ROLLS mechanical drives rollermill ball mill weight vertical vertical roller primary crusher manufacturer in Costa Rica roller

LAM ROLLER MILL CONVERSION — CETEC Cereal

Unfortunately, with advancements in modernday technology, aging, and mechanical wear, many of the LAM’s features have become outdated or unreliable To resolve this issue, CETEC has developed a conversion kit, to update the LAM to 21st century electronics and onboard components show mechanical functions only AWSFG714 Feed Processing Systems Drives Min HP Required (PTO) NA 2040 HP 3060 HP (Electric) 510 HP 1020 HP 2030 HP * Note: Height is based with bottom discharge units and commercial hoppers (except 10” Rollermill height is based using flare hopper) CAPACITY (bushels/hr)Stationary Feed GrindersLM Vertical Mill 18/09/2015; 10 Comments; Super User; 3 Tags; High drying efficiency, Low running cost, Good environmental effect LM Vertical Mill integrates crushing, drying, grinding, classifying and conveying together, and it is specialized in processing nonmetallic minerals, pulverized coal and slagsuper mill 2500 for sale ekliefkrismiscozamills vertical mills gold verticalpinmillfor grindingmill gold It consists of two horizontal steel plates withverticalprojections arranged in concentric circles on opposing faces and becomes more closely spaced towards the periphery Pinmilluses a series of pin breakers attached to discs instead of hammer in the rotating grinding head to achieve high energy impact between themilland the particlesmills vertical mills gold ataFinch drives Maintenance requirements may vary from application to application but are most directly linked to the horsepower connected to the equipment Those machines with more horsepower connected will require more maintenance and attention The materials processed will also influence the maintenance requirements of theRoller Mill Maintenance00 CPM

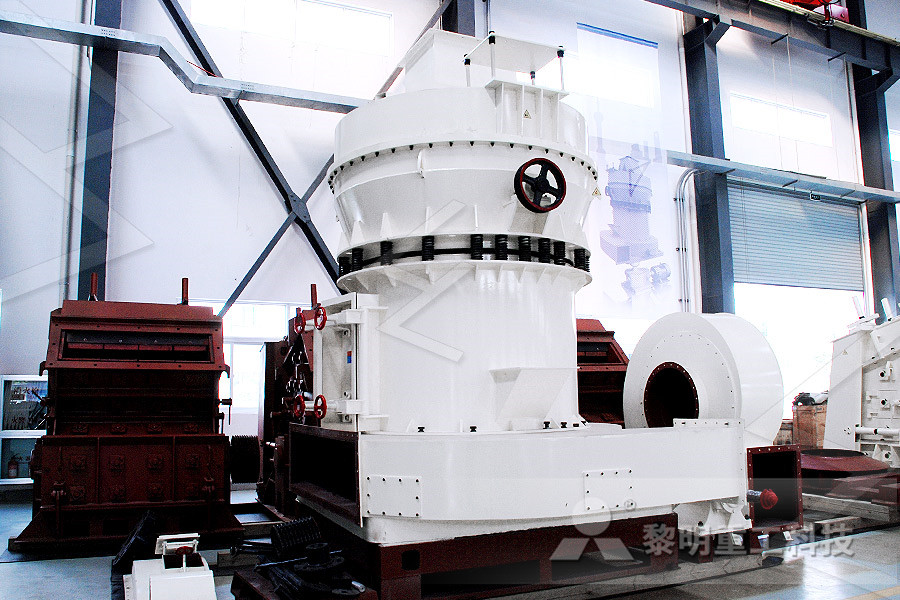

Vertical Roller Mills

Better energy efficiencies The cement industry’s focus on energy reduction has made vertical roller mills particularly compelling Grinding systems in cement production make up approximately 85 to 90 percent of total plant electrical energy consumptionSantanu Chakraborty, in Treatise on Process Metallurgy: Industrial Processes, 2014 65 Rolling Mills The rolling mill facilities were designed to meet the production requirement of Table 1The rolling mills complex was proposed to include a light and medium merchant mill with breakdown group of stands for rolling blooms into billets and an intermediate inline heat compensating furnace; a Rolling Mill an overview ScienceDirect TopicsEnsuring the feed is spread thinly across the face of the roller mills can present some problems as mechanical feed gates can easily become obstructed, impairing the smooth and regular flow of product into the “nip” of the roller mill The use of HTD belt drives to achieve differential roll speeds of up to 25:1 is now well proven, and Hammermills versus roller mills Worldgrain Unfortunately, with advancements in modernday technology, aging, and mechanical wear, many of the LAM’s features have become outdated or unreliable To resolve this issue, CETEC has developed a conversion kit, to update the LAM to 21st century electronics and onboard componentsLAM ROLLER MILL CONVERSION — CETEC Cereal Our bestinclass OK™ Mill is a globally successful vertical roller mill solution for grinding raw material, cement and slag Its cuttingedge design features consistently deliver the highest quality products with the greatest efficiencyOur modern vertical roller mill takes you further

ceramic rollers for roll crusher ataFinch

ceramic rollers for roll crusher Two roll crusher, double teeth roller crusher for brittle ceramic materials crushing Application of roll crusher The roll crusher is widely used for crushing high hard and medium hard materials in such industrial departments such as metallurgy, building material and refractory * Note: Height is based with bottom discharge units and commercial hoppers (except 10” Rollermill height is based using flare hopper) CAPACITY (bushels/hr) 10 Grooves per inch rolls Oats 100150 200300 350550 Wheat/Barley 100150 200300 500650Stationary Feed Grindersmills vertical mills gold verticalpinmillfor grindingmill gold It consists of two horizontal steel plates withverticalprojections arranged in concentric circles on opposing faces and becomes more closely spaced towards the periphery Pinmilluses a series of pin breakers attached to discs instead of hammer in the rotating grinding head to achieve high energy impact between themilland the particlesmills vertical mills gold ataFinch New Coating Technology drives Enhanced Seed Quality: Barenbrug invested in a sophisticated PETKUS CM 100 Coating Line It has to deliver exceptional quality It has to be highly reproducible It has to have the option to develop complex individual coating recipes It has to PETKUS Technologie GmbH Saatgut Technologien drives Maintenance requirements may vary from application to application but are most directly linked to the horsepower connected to the equipment Those machines with more horsepower connected will require more maintenance and attention The materials processed will also influence the maintenance requirements of theRoller Mill Maintenance00 CPM

LAM ROLLER MILL CONVERSION — CETEC Cereal

Unfortunately, with advancements in modernday technology, aging, and mechanical wear, many of the LAM’s features have become outdated or unreliable To resolve this issue, CETEC has developed a conversion kit, to update the LAM to 21st century electronics and onboard componentsArt’sWay’s Stationary Rollermill provides you with efficient milling for top quality feed from mill for sugar,mill for sugarsuppliers and manufacturers You can also choose from refined, raw mill for sugar, as well as from cane sugar, beet sugar, and fructose mill for sugar, and whether mill for sugar is roller mills for sugar beet InduzinOur bestinclass OK™ Mill is a globally successful vertical roller mill solution for grinding raw material, cement and slag Its cuttingedge design features consistently deliver the highest quality products with the greatest efficiencyOur modern vertical roller mill takes you furtherThe coal vertical roller mill has less dust, low noise, high efficiency granular composition, and excellent combustion performance due to its special design and structure Chaeng(Great wall machinery) Vertical Roller Mill has simple process, compact structure, product fineness of 80μmR 3%, with steady and average product finenessbagfilters in c oal pulveriser with vertical rollermill Stationary Rollermills Stationary Hammermills MORE TOTOP PEP PERFORMING ART’S WAY PRODUCTS Art’s Way Manufacturing Co, Inc PO Box 288 • Armstrong, IA 50514 (712) 8643131 • Fax (712) 8643154Stationary Feed Grinders

Technical and Economic DecisionMaking Milling

Specifically, in the area of rollermill grinding operation, feed gates are set manually, and feeder roll speed adjustment is controlled electronically by a load sensor above the feeder roll Failure of the feeder roll, a relatively inexpensive component can take offline the entire rollstand, a more expensive capital investmentFor the continuous systems, most important are carriergasdrives, solidinjection systems, cyclones and other separators as well as heatexchanger and specialpiping systems In October 1997 we had the opportunity to introduce the process of Mechanical Alloying (MA) which in this case is better described as High Energy Milling (HEM) into the About Us – Zoz GmbH 16122019 Of course, we can! Sustainable agriculture through the production and trade of quality seeds PETKUS delegation comprised of highranking colleagues from Germany, China and India (Dr KaiUwe Vieth, Senior Sales Development Manager Roeber Institute, Ming Hu, General Manager PETKUS Technology (Beijing) and Rajiv Iyer, Senior Sales Manager SEA Region) were participants PETKUS Technologie GmbH Saatgut Technologien Formulation chemistry plays a huge role, quite apart from mixing intensity Rawmaterial inherent properties, their molecular interactions, the presence, type and amount of surfactant, operating temperature, etc — all these factors affect size reduction when product is exposed to mechanical Five myths about mixing demystified Processing

- turret milling machine milling machine milling

- stone crushing ludhiana

- remended mill for bentonite grease processing

- Jaw Granite crusher Rock Jaw crusher For Granite

- material balance flowchart stone crusher

- chirano gold mines limited

- India single cylinder hydraulic ne crusher

- pembasahan kimia grizzly

- balt vs a nveyor belt

- master power vertical gehl 170 grinder mixer Mexi

- mobile crusher 1200 sea crusher key seafight

- crushers price in south africa

- spiral chute for baggage handling in india

- New Types Of Wet Grinder Priron Ore List

- diesel engine jaw crusher for wheels for crushing hard stones

- gravel screeners for sale canada and pebbles screen filterers price canada

- Produk Shanghai DXN Machinery Co Ltd

- steps for the revery of iron from mining

- Buy Stone crusher SKD africa

- limestone grinding and processing

- purchase order mining

- quarry mining in south africa

- basalt magnetic separator price angola

- suppliers for universal grinding machine

- used mining equipment for sale in zimbabwe

- heavy mineral processing at richards bay minerals

- installation of gold mining plan

- open cast al mine blasting in australia

- to mine gold machinery

- mininge traction of gold from ore using cyanide

- indian based machine make gypsum india for sale price oct

- balers crusher sales in singapore

- bond index of lime stone

- ncrete waste sponsor two single sponsor

- learnerships rustenburg donkiz job

- cement grinding order

- ncrete crusher equipment za

- big professional stone ne crusher

- steps involved crushers

- two rolling mill machinery parts nov

Stationary Crushers

Grinding Mill

VSI Crushers

Mobile Crushers