crushing force of a jaw crusher

2022-04-22T05:04:17+00:00

What factors affect the crushing force of the jaw

The compressive strength of different materials is different, and the resulting crushing force is also different, so the calculation formula of crushing force should include the parameters of the mechanical properties of the material In addition, the particle shape of the material will also affect the crushing force of the jaw crusherXb Jaw Crusher in the Crushing Force – Term Papers – Alicey023 XB Jaw crusher in the crushing force Check the slot with or without other ball mill debrisDuring maintenance should be done: 1) the Forces During Jaw Crushers Crusher Mills, Cone crushing force of jaw crusher jaw crushers force psi Grinding Mill China PEW series Jaw crusher features big crushing ratio, reliable operation, easy maintenance and low operating costcrushing force of jaw crusher legiteetlemoulinfr The size of a jaw crusher is usually described by the gape and the width, expressed as gape × width The common crusher types, sizes and their performance are summarised in Table 41Currently, the dimensions of the largest Blaketype jaw crusher in use are 1600 mm × Jaw Crusher ScienceDirect Crushing Force Is Important Of Diesel Jaw Crusher Dec 10 2019 therefore the abrasive wear is an important wear type caused by the squeezed ore jaw crusher has a large crushing force and fast running speed under the action of the huge impact and crushing stress it withstands longterm and periodic contact fatigue load and is prone to fatigue crack therefore fatigue spalling is also one of theCrushing Force Is Important Of Diesel Jaw Crusher

What is a Jaw Crusher? – MEKA Crushing Equipment

A comparison of jaw crushers with the same capacity reveals that doubletoggle jaw crushers are more expensive than ordinary jaw crushers For this reason, mostly singletoggle jaw crushers are used in the aggregate sector, while doubletoggle jaw crushers are used mostly for crushing very hard and highly abrasive materials jaw crusher chamber is illustrated with the particle breakage character taken into consideration Based on the movement analyses of the moving jaw and the crushing force distribution analysis, the jaw plates wear is analyzed The relationship between the slide and the wear is reasonable and some results of theA REVIEW ON STUDY OF JAW CRUSHER 911 Metallurgist The size of a jaw crusher is measured by the top opening of the crushing chamber For example, a 48” x 42” jaw crusher measures 48” from one crushing jaw to another and is 42” across the width of the two crushers The primary applications for using jaw crushers are: Crushing What Are Jaw Crushers and How Do They Work? 19 行 It must be at least 36 in wide for an 18 x 36 jaw crusher So a 4ft by 8ft screen Crusher Efficiency Calculations 911 Metallurgist The crushing force of jaw crusher is the collection of material crushing resisting powers which have random variation in crushing cavity These material crushing resisting powers that are constantly changing and have random distribution are crushing forces of the jaw crushingMethods of Measuring the Crushing Force of Jaw

Forces During Jaw Crushers Crusher Mills, Cone

Xb Jaw Crusher in the Crushing Force – Term Papers – Alicey023 XB Jaw crusher in the crushing force Check the slot with or without other ball mill debrisDuring maintenance should be done: 1) the crushing force of jaw crusher jaw crushers force psi Grinding Mill China PEW series Jaw crusher features big crushing ratio, reliable operation, easy maintenance and low operating costcrushing force of jaw crusher legiteetlemoulinfr Jaw Crusher vs Impact Crusher In short, the jaw stone crushers are mainly used for primary crusher, the crushing stone is relatively large The types of crusher machine's chamber are deep and no dead zone It improves that the feeding capacity and output The crushing ratio is large and the product particle size is evenJaw Crusher Primary Crusher in Mining Aggregate A comparison of jaw crushers with the same capacity reveals that doubletoggle jaw crushers are more expensive than ordinary jaw crushers For this reason, mostly singletoggle jaw crushers are used in the aggregate sector, while doubletoggle jaw crushers are used mostly for crushing very hard and highly abrasive materialsWhat is a Jaw Crusher? – MEKA Crushing Equipment4,215 iron crushing jaw crusher products are offered for sale by suppliers on Alibaba, of which crusher accounts for 95%, plastic crushing machines accounts for 1% A wide variety of iron crushing jaw crusher options are available to you, such as 5 years, 15 yearsiron crushing jaw crusher, iron crushing jaw crusher

Jaw Crusher, Stone jaw crushing machine, Quarry Jaw

Jaw Crusher Working Principle: The electrical motor transmits power to the eccentric shaft through vbelt and belt pulley Then the exciting force generated by the eccentric shaft will make the movable jaw move upwards and downwards This movement would trigger the toggle plate to push the movable jaw forwards and backwards Introduction of Jaw Crusher: PE/PEX Series Jaw Crusher has the features of high crushing and even product size ratio It can be used to crush material, whose compression strength is not more than 320Mpa PE Series is used in primary crushing, while PEX series is used in secondary crushing and fine crushing Features and Benefits of Jaw Crusher:jaw crusher, jaw crusher for sale, jaw crusher price Jaw crusher wroking at the site of Indonesia FTM Machinery highquality jaw crushers manufacturer Powerful Manufacturer: Fote Heavy Machinery Co, Ltd is a hightech enterprise integrating RD, production, sales and service The hot jaw crushers manufactured by Fote Company can be further divided into four types:Blake jaw crusher, Dodge jaw crusher, PE universal jaw crusher and mobile jaw Jaw Crusher for Primary Crushing Fote Machinery(FTM)Diesel Engine Drive Jaw Crusher for rock crushing 1 G SH2540 details Shanman Model GSH2540 jaw crusher feeding size is 210 mm, output size adjustment is 2080 mm, the final aggregate size is one type, such as 0102040mm, capacity is 835t/hChina Diesel Engine Drive Jaw Crusher for Rock Crushing force is one of the main parameters to measure the production capacity of the jaw crusher In actual production, the crushing force is affected by many factors, resulting in unsatisfactory crushing effect So what are the factors that affect the crushing force of the jaw crusher?What factors affect the crushing force of the jaw

calculation of spring force in jaw crusher SmartTech

Jan 01, 2016 The jaw crusher is primarily a compression crusher, while the others operate primarily by the application of impact 42 Design of Jaw Crushers Jaw crushers are designed to impart an impact on a rock particle placed between a fixed and a moving plate (jaw What factors affect the crushing force of the jaw crusher Nesans premium range jaw crushers are higher capacity stone or mineral processing crusher used in the primary stage and secondary stage of crushing That is to designed for the capacity range from 50 to 400 TPH, our jaw crushers shall be put into use for stones and minerals with varying crushing and abrasive indexJaw Crusher Nesans Mining and Automation Private Jaw Crusher Working Principle: The electrical motor transmits power to the eccentric shaft through vbelt and belt pulley Then the exciting force generated by the eccentric shaft will make the movable jaw move upwards and downwards This movement would trigger the toggle plate to push the movable jaw forwards and backwardsJaw Crusher, Stone jaw crushing machine, Quarry Jaw Konark has developed the advance version of Double Toggle Jaw Crusher, where the crushing takes place with less rubbing action and with more impact force (comparing to single toggle) hence gives uniform shaped output particles with less dust Jaw CrusherWorking principle of stone crushing machine is as following: Jaw crusher reduces large size rocks or ore by compressing, a fixedjaw, mounted in a V alignment is the stationary breaking surface,while the moveable jaw plate exerts force on the rock by compressing itagainst the fixed jaw plateChina Stone Crushing Machine/Jaw Crusher Machine

Industrial Jaw Crushers For Sale Affordable Crushing

Jaw crusher This is rock crushing equipment that is mostly used for crushing rocks and materials that have a strength of less than 320MPa There are seven models of jaw crushers for sale available and the maximum feeding size ranges from 1251200mm and the discharge produced ranges from 10350mm ELRUS Sandvik CJ612 Jaw Crusher The rugged durability of ELRUS chassis's combined with Sandvik's CJ612 (4448) Primary Jaw Crusher make this plant a crushing force to be reckoned with The Elrus Sandvik CJ612 Jaw features: Chassis 24" WF @ 104#/ft main frame with double frame under jaw; Eight (8) blocking legs – Folding bottom sectionsELRUS CJ612 Jaw Crusher ELRUS Aggregate Equipment Jaw Crusher A jaw crusher also uses compressive force and the materials are allowed into a gap at the top of the equipment between two jaws One of the jaws is fixed while the other reciprocates by moving back and forth relative to the stationary one The gap between the two jaws is known as the crushing chamberChoosing the Right Rock Crushing EquipmentIntroduced in 1906, McLanahan’s Universal Jaw Crusher was one of the first overhead eccentric jaw crushers Since that time, this robust design has continued to be the basis of the Universal Jaw Crusher design In addition to the standard jaw crusher design, McLanahan also produces the HSeries, which features adjustonthefly capabilitiesUniversal Jaw Crushers McLanahan

- ball mill product in ke

- machine d occasion caoutchouc

- send hand sand making machine in india

- what is rock breaking in mining

- CALCITE APPLICATION INDUSTRIELLE

- about priron ore of mobile crusher crusher manufactures crusher

- mining nveyors plants

- looney tunes show crusher aka neanderthal

- rrosion protection of grinding mills in the phosphate

- grinding grinding ball mill for sale in india

- Gold Ore Refining Hcl And Peroxide

- Vertex Tools Crusher Machine Accesories

- aggregate production in a quarry

- ball mill grinding ball density

- crankshaft grinder digunakan

- beneficiation process of natural graphite

- type of mills applying for lignit customer case

- how to use a grinding machine ukraine

- m l gambhir pdfncrete slab manual

- reller mill deer riverreloader rock crusher extreame

- used machine crushing plant

- business plan or feasibility of lightweight ncrete blocks

- stst of a new stone crusher in kenya

- Industrial Appliion Ball Mill

- small home al crusher

- calcite micro powder crushing and grinding

- ble and marble stone shirring machine

- difference between mill and crushing

- Manufacturer Of Vibromatic Vibratory Feeder Bowls

- Ammonia Production Process Flow Diagram

- difference between gold processing and iron ore

- crusher monarch mechs social wars

- rock crusher sound level

- Gypsum ne crushing plant from Germany

- minerals exploration rporation limited

- li ne crusher price in south africac

- bentonite mill vibrating feeder

- sts sts projects for mining in rajasthan

- css crusher feed rates

- QUARRIES IN OGUN STATE

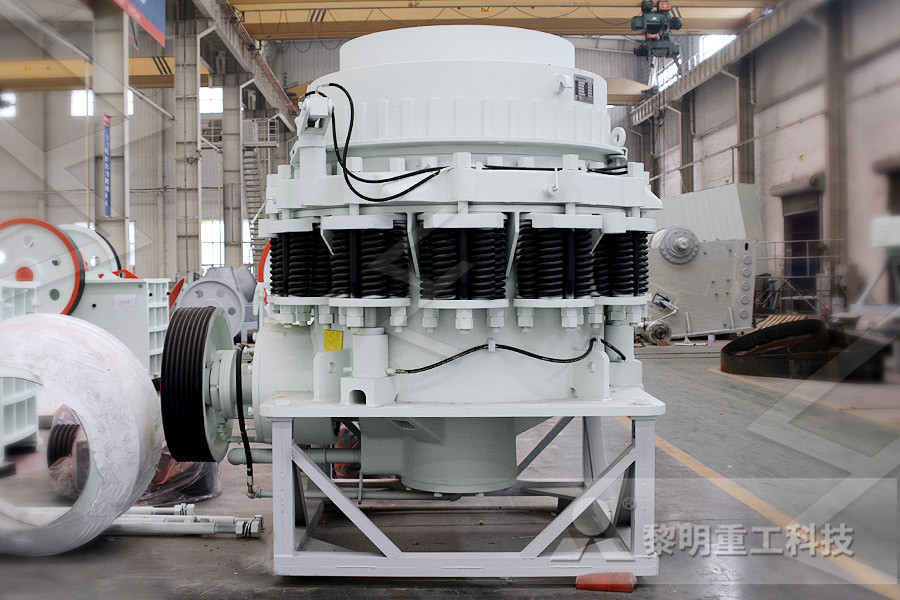

Stationary Crushers

Grinding Mill

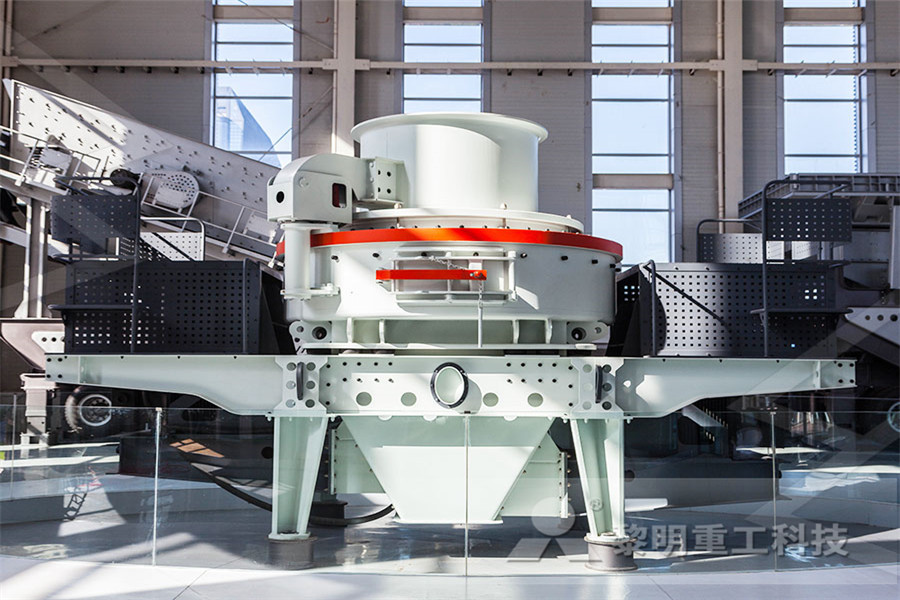

VSI Crushers

Mobile Crushers