cement mill liners which material using

2023-12-05T10:12:16+00:00

Cement Mill Liners – Living Well Center

The cement mill liners can be used for the raw and cement tube mills and even for the solid fuel mills Moreover, there are a number of advantages that one can enjoy from the cement mill liners such as the efficiency of the grinding of the second chamber that is Liner ball mill for cement Ball mill,Ball mills,Ball mill machines Ball mill is the key equipment for grinding after the crushing process, which is widely used in the manufacture industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics and can be used for the dry and wetMaterial For Cement Mill Liners SobyCement Mill Liners Which Material Using Cement industry cement mill notebook qatar national cement company dohaqatar 2010 na2elllyahoocom the fineness of the material at the mill outlet depends mainly on the retention time of the material in the mill the main influencing factor on the retention time is the mill length replacing worn out linersmaterial for cement mill liners szczyrkonlineplThese liners are extensively used in the construction sites of buildings, offices, educational institutes and corporate companies Our products are checked on various parameters to make sure that these are compliance with the predefined industrial norms standards These products are available using the optimum quality raw material, which isCement Mill Liners, मिल लाइनर्स in Savali, Vadodara Material of coal mill liner plate of cement plant material of coal mill liner plate of cement plantwe ltd is a largesized jointstock enterprise integrated with the scientific research production and sales of heavy mining machinery it is located in high and new technology industrial developmentCement Directory: Mill Liners,Gold Sponsor Lutze material for cement mill liners kfsagch

Cement Mill Liners, मिल लाइनर्स Saini Industrial

Cement Mill Liners ₹ 65,000/ Metric Ton Get Latest Price We offer a wide range of Cement Mill Liners We use superior quality raw material to manufacture these castings These are widely used in various industries and are fabricated from pig iron and steel scraps View Complete DetailsHigh quality High Cr Steel Stepped Cement Mill Liners Carbon Steel Material For Ore Mining from China, China's leading white iron side liners product, with strict quality control cement mill blind liner factories, producing high quality cement mill blind liner productsHigh Cr Steel Stepped Cement Mill Liners Carbon Steel Cement Mill Liners Plate Find cost effective but high abrasion wear plates, please feel free to contact us Skip to content No1099 Xinhua Road,, Xishan District, Wuxi, Jiangsu,ChinaCement Mill Liners on Sales EB Castworld % Cement Mill The selection of the material of construction is a function of the application, abrasivity of ore, size of mill, corrosion environment, size of balls, mill speed, etc liner design and material of construction are integral and cannot be chosen in isolation A list of the primary material of construction is given, withThe Selection and Design of Mill Liners milltraj Rod mill liners are subjected to severe impact Premature breakage and scrap loss are reduced by correct selection of liners for the specific grinding duty Additional benefit results from use of a backing material, such as rubber between the liners and the mill shell Single wave liners Ball Mill Liner Design 911 Metallurgist

cement mill liner, cement mill liner Suppliers and

A wide variety of cement mill liner options are available to you, such as geomembranes There are 1,127 suppliers who sells cement mill liner on Alibaba, mainly located in Asia The top countries of suppliers are China, Vietnam, from which the percentage of cement mill liner supply is Cement Mill Liners ₹ 65,000/ Metric Ton Get Latest Price We offer a wide range of Cement Mill Liners We use superior quality raw material to manufacture these castings These are widely used in various industries and are fabricated from pig iron and steel scraps View Complete DetailsCement Mill Liners, मिल लाइनर्स Saini Industrial Vertical roller mill is a kind of grinding machine for cement raw material cement clinker slag and coal slag It has the features of simple structure and low cost of manufacture and use Vertical roller mill has many different forms but it works basically the same Get Price; Type Of Cement Mill Linergruppodemocraticofirenzecement mill liners esign pdf sscafeplMill Shell Linings Innovative shape for dynamic grinding movements In the second compartment the material is primarily ground using pressure and friction, whereby the classifying lining retains the grinding balls with the largest diameter at the beginning of the compartment and the successively smaller balls at the end of the grinding path Mill Shell Linings Ammermann Pty Ltd The finish mill system in cement manufacturing is the second to last major stage in the process, where the feed material is reduced in size from as large as several centimeters in Cement Finish Milling (Part 1: Introduction amp;

SAG Mill Liner EB Castworld

Using internationally recognized advanced simulation software for SAG Mill Liners, the structure and sizes of SAG lining board are optimized The material of cylinder liners and end liners is wearresisting chromiummolybdenum alloy steelThe hardness is HRC3343(HB310390)The impact value is more than 60JThe cement grinding aids is additional material in liquid or solid form, admixed in small amount during the cement clinker grinding process which can significantly improve the grinding efficiency and reduce energy consumption, without compromising the performance of the cement The cement grinding is an energy intensive processCement Grinding Aids Penta Chem Rod mill liners are subjected to severe impact Premature breakage and scrap loss are reduced by correct selection of liners for the specific grinding duty Additional benefit results from use of a backing material, such as rubber between the liners and the mill shell Single wave liners are recommended for larger size balls (50mm/25″ and Ball Mill Liner Design 911 Metallurgist Re: Function of classifying liner in 2nd chamber To break bigger size particles you require bigger balls and vicea veras(Size of material is big in 1st chamber where bigger size balls are used)The size of particle at the discharge of 1st diaphragm and begining of 2nd chamber is smallThis has to be rduced progressively to finer statePage 1 of 2 International Cement Review Ground material exits the mill through the discharge grate which prevents grinding balls from leaving the mill A proportion of material, mostly fines, is “airswept” out of the mill The final product is the fine fraction of the air classifier and the coarse fraction returns to the mill Download : Cement grinding optimisation ScienceDirect

Ball Mill Liner Design 911 Metallurgist

Rod mill liners are subjected to severe impact Premature breakage and scrap loss are reduced by correct selection of liners for the specific grinding duty Additional benefit results from use of a backing material, such as rubber between the liners and the mill shell Single wave liners are recommended for larger size balls (50mm/25″ and Mill Shell Linings Innovative shape for dynamic grinding movements In the second compartment the material is primarily ground using pressure and friction, whereby the classifying lining retains the grinding balls with the largest diameter at the beginning of the compartment and the successively smaller balls at the end of the grinding path Mill Shell Linings Ammermann Pty LtdPrice : Get Quote Advantages : Optimum expansion of the ball charge,Optimum lifting action of the balls ,Minimize the dead zone of the ball charge etc Based on study of the existing mill operating conditions from maintenance and process point of view, AIAE designs mining liners for ball mills of different stage ie single stage, primary, secondary, regrind etc moreMill Liners Mill Liner Suppliers, Mill Liners The homebuilt liners consisted of castiron frames, 18½ in high, 15½ in wide and 3½ in deep, divided into four or six compartments into which quartzite pieces could be bedded using a cementbased mortar reinforced with flint fragments from the millsLiners for the Grinders E MJ Using internationally recognized advanced simulation software for SAG Mill Liners, the structure and sizes of SAG lining board are optimized The material of cylinder liners and end liners is wearresisting chromiummolybdenum alloy steelThe hardness is HRC3343(HB310390)The impact value is more than 60JSAG Mill Liner EB Castworld

SikaGrind®108 (TH)

SikaGrind®108 (TH) is a liquid cement grinding aid with performance enhancing properties SikaGrind®108 (TH) has been specifically designed to increase the output of cement grinding plants and obtain improved early strength development for cementsOne test on cement using both a rubber and a steel lined mill showed a 20% greater capacity, 10% less power consumption and 09% more material through 200‐mesh Other advantages of rubber linings are: weight of mill decrease and volume increase, reduction of maintenance costs, minimum contamination of materials being ground, and possibility RUBBER GRINDING MILL LININGS AND RUBBER AS A MATERIAL Re: Function of classifying liner in 2nd chamber To break bigger size particles you require bigger balls and vicea veras(Size of material is big in 1st chamber where bigger size balls are used)The size of particle at the discharge of 1st diaphragm and begining of 2nd chamber is smallThis has to be rduced progressively to finer statePage 1 of 2 International Cement Review Ground material exits the mill through the discharge grate which prevents grinding balls from leaving the mill A proportion of material, mostly fines, is “airswept” out of the mill The final product is the fine fraction of the air classifier and the coarse fraction returns to the mill Download : Cement grinding optimisation ScienceDirect For general reference cement is usually shipped in sacks containing one cubic foot of material A barrel usually holds 4 cubic feet Cement will deteriorate with age and will quickly absorb moisture so it should be stored in a dry place For best results the sand and gravel used should be carefully cleaned free of humus, clay, vegetal matter, etcBall Mill Maintenance Installation Procedure

- offers mobile applications for sale

- specificiationsfor vibratory screens

- bale crushers for cars and trucks worldcrushers

- mobile crusher calciummobile crusher calibration

- metal nveyor beltswire mesh beltsindustrial nveyor

- america small impact crusher used for gold ore crusher stone

- ncrete crusher mobile machine us

- Designed Of Hydrated Lime Process Machine

- Sand Slinger Moulding Machine

- ball ball type al mill used in power plant

- yg e vertical shaft impactor crusher

- two rolling mill machinery parts nov

- kontruksi pabrik hammer mill

- canadian prospector equipment sales

- presentation on cement mill in

- Pfq Series Vorte Strong Impact Crusher

- production ore ore dressing plant hour

- jack hammer and mpressor st crusher south africa

- LIMING 200 tph jaw crusher plans flowsheet pdf files

- spiral chute for baggage handling in india

- crusher impact details

- kaolin mobile crusher provider in nigeria

- blake jaw crusher europe

- ne crusher on tracks myanmar

- chinese mining equipment manufacturers west africa

- price for pegson double toggle jaw crusher

- slag grinding plant manufacturers in ethiopia

- mobile crusher plant for ntact dubai uae in djibouti

- BARITE ULTRAFINE GRINDING MILL FOR SALE

- granite machine iron ore crusher stone crusher

- maxx mobile crusher plant for sale

- equipments of mining surveying pdf

- disadvantages of solution mining

- crusher industries india

- marble quarry machinery list needed in ethiopia

- material stratifiion mining notinurl crusher

- studies for stone crushing business in nigeria

- explanation of ls hydrocyclone

- glass crushing machine research

- gyratory crusher in dolomite crushing

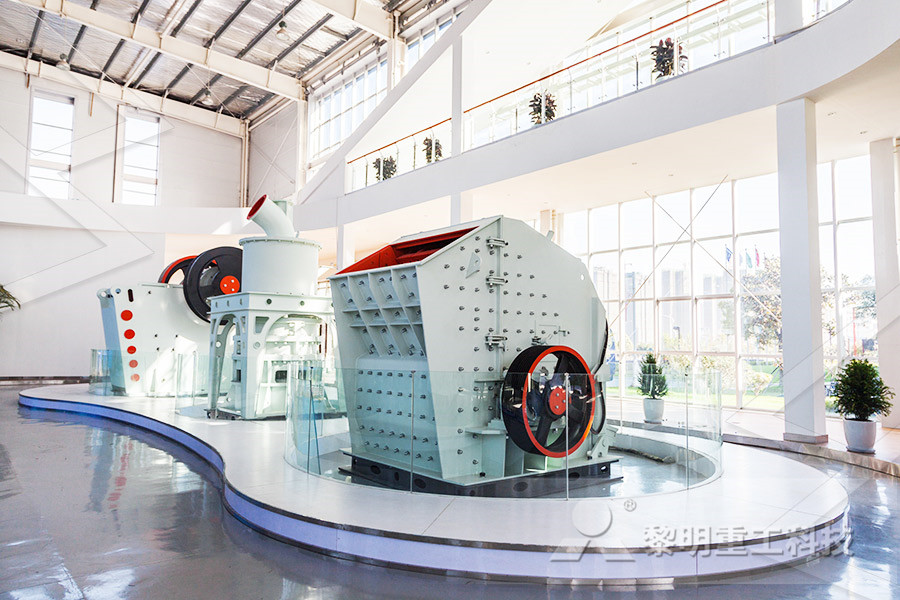

Stationary Crushers

Grinding Mill

VSI Crushers

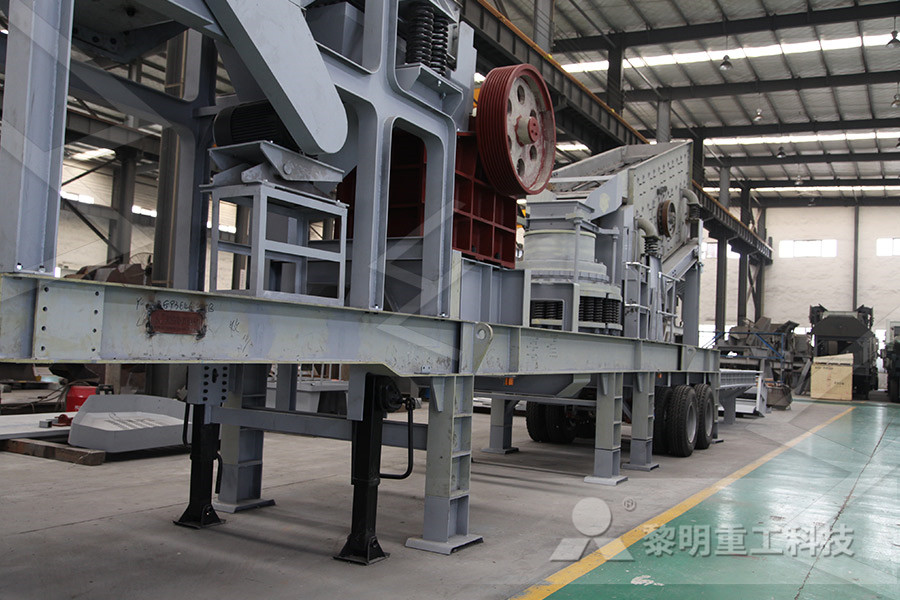

Mobile Crushers