leadzinc impellers slurry pump

2022-09-29T23:09:21+00:00

impeller of slurry pump, impeller of slurry pump

3,975 impeller of slurry pump products are offered for sale by suppliers on Alibaba, of which pumps accounts for 57%, axial flow fans accounts for 1% A wide variety of impeller of slurry pump options are available to you, such as electric, hydraulic Another feature of slurry pump impellers is the pump out or expelling vanes on the back and front shrouds These perform the dual function of reducing pressure (thus inhibiting recirculating flow black to the impeller eye, and reducing stuffing box pressure) and keeping solids out of the gaps between the casing and impeller Slurry Pump Impellers, Warman Slurry Pump Impellers China Slurry Pump Impellers manufacturers Select 2021 high quality Slurry Pump Impellers products in best price from certified Chinese Water Pump, Pump Parts China Slurry Pump Impellers, Slurry Pump Impellers Ceramic Slurry Pump Impellers are made of Silicon nitride bonded silicon carbide material,It is mainly used for Wear and Erosion resistant working applications Tobee ® manufactures high quality slurry pump ceramic impellers and liners replacement parts for some all AH slurry pumps, which are 100% INTERCHANGEABLE Tobee ® ceramic slurry pump impellers with silicon nitride bonded Ceramic Slurry Pump Impellers Tobee Pump Pumping slurry is very difficult, you have to avoid pump blockage at all costs Impeller size The size of the slurry pump impeller must be considered to ensure that it can withstand abrasive wear Compared to liquid pumps with less abrasive properties, slurry impellers are generally larger in sizeWhich Impeller Is Suitable For Slurry Pump

Ceramic slurry pump impeller Libra Slurry Pump Parts

We proudly manufacture quality ceramic slurry pump liners and other replacement parts for some famous pump manufactures, which are 100% REVERSE INTERCHANGEABLE, no need to change your stock Partial list of Impellers available for the contemporary Slurry pump alloy impellers are normally made in high chromium alloys, special materials are also available Our slurry pump alloy impellers are also available to suit: Warman AH pumps, L pumps, M pumps and HH pumps Alloy Impellers Warman Slurry Pumps; HS B1127: 15/1BAH: HS B15127: 2/15BAH: HS C2147: 3/2CAH:Slurry Pump Alloy Impeller – Honstar Sunbo Pump stocks a range of slurry pump parts which have been developed for abrasive applications in mines, quarries, sand and gravel etc, and are used widely across the globe in mineral processing and all other solid mixture applications All Sunbo Pump aftermarket slurry pump parts save you money and energy of your slurry pump Slurry Pump Metal Impeller Wear Parts Slurry Pump Keywords: Corrosive wear; Slurry pump; Failure 1 Introduction Among the equipment used in the wet process manufacture of phosphoric acid, slurry pumps fail very often, mainly resulting from excessive weight losses of their impellers which run under combined erosioncorrosion and erosive wear conditions or corrosive wear conditionsFailure analysis of the impeller of a slurry pump Honstar slurry pump parts Co, Ltd is an independent manufacturer of replacement parts for slurry pumps, and is not a distributor or agent for, nor affiliated in any way with the OEM All OEM names, trademarks, pump models and part numbers are for reference onlyImpeller Clearance Adjustment For Slurry Pumps –

centrifugal mill discharge corrosion resistant slurry

Centrifugal Slurry Pump Model K to supply pumps with a number of exotic corrosion resistant paints Materials of Construction AR Wilfley Sons produces model K pumps in a variety of hard irons and stainless steels including proprietary allows specially developed to stand up to the difficult erosivecorrosive conditions found in slurry servicesRoot Lead Ore Handling Sand Suction Gravel Pumps Dredging / quarry pumpsour range of dredging / quarry pumps are specifically designed for handling sand, gravel and heavy abrasive slurriesthese centrifugal pumps with closed impellers are robustly constructed using carefully selected materials and unique contour components which offersProduction Line Russia Lead Ore Crushing Plant High Precision, Advanced flotation beneficiation plant About product and suppliers: If you are in the mining industry or have a business involving minerals, flotation beneficiation plant is an essential piece of equipment for you At Alibaba, you can find a great selection of flotation beneficiation plant machines that work precisely and can ease your work greatlyflotation beneficiation plant high efficiency flotation beneficiationChina Inner Mongolia 1200tpd LeadZinc Processing Plant xinhai Flotation zinc concentrate was pumped into the efficient improved thickenerunderflow entered into the ordinary agitation tank and was pumped into the highpressure press filter for filtrationfilter cake was transported by the belt conveyor to the concentrating pondchina xinhai agitation tank filetypeThe slurry of goldbearing leachate and solid residue leaving the leaching circuit contains in the range of 15 ppm gold and is directed to an RIP circuit, where gold and copper are loaded onto a strongbase resin to 15 kg/t Au and 1025 kg/t Cu Copper is eluted from the resin using ammonia thiosulfate 200 g/L and gold is eluted Inquire Nowmineral gold flotation cell maximum solids 」

Silver Flotation Machines Machine In Europa Fixelo

Good Quality Gold Silver Flotation Cells Machineflotation Flotation Machine Compared with flotation cells its uniqueness lies in big size lower power loss and light wear and tear of the impeller Flotation machine is commonly used ore flotation equipment in the ore dressing plants and plays a crucial role in the fast development of mining industry in ChinaFlotation Mining Equipment Appropriate Process Technologies Flotation system is based around a group of 6 float cells arranged in a circular tank each individual cell fitted with impellers air spargers and froth launders Host of benefits in the design better mixing in slurry applications resulting in greater efficiency for reactions and a greater uniformity within the tankMineral Processing Equipment Processing The copper ore slurry from the grinding mills is mixed with milk of lime (simply water and groundup limestone) to give a basic pH, pine oil (yes, it comes from trees a byproduct Froth Flotation Process Mineral Processing MetallurgyThe Froth Flotation Process is about taking advantage of the natural hydrophobicity of liberated (well ground froth flotation process use for mining copperpart for froth flotation process in ore ore dressing Froth flotation ore dressing BritannicaFlotation, in mineral processing, method used to separate and concentrate ores by altering their surfaces to a hydrophobic or hydrophilic conditionthat is, the surfaces are either repelled or attracted by waterpart for froth flotation process in ore ore dressingdispersion in mineral Glossary of TermsDispersion The splitting of white light into the colors of the spectrum When white light dispersion in mineral processing 」

lead and zinc wear resistant rubber slurry pump

Slurry Pump, Rubber Slurry Pump, Dewatering Pumps Improvement Slurry pump impeller and the casing are lined with Xinhai high wearresistant rubber ensuring that the pump body is not subject to wear In the same project, the service life of Xinhai slurry pump is 2 times longer than other metal pump life reaching the international top qualityCentrifugal Slurry Pump Model K to supply pumps with a number of exotic corrosion resistant paints Materials of Construction AR Wilfley Sons produces model K pumps in a variety of hard irons and stainless steels including proprietary allows specially developed to stand up to the difficult erosivecorrosive conditions found in slurry servicescentrifugal mill discharge corrosion resistant slurry rubberlined slurry pump flowserve lime and mud caco 3 and tio 2 air pollution gypsum slurries absorber pumps water pollution mill effluent complementary pumps designs flowserve can also provide the following pumps: type m hard metal, abrasive slurry pump mj and mjc vertical slurry pumps titan slurry heavyduty, dual case, lined slurry pump tobee® metal lined slurry pumpthe horizontal slurry metal lined mill discharge sand chemical mud slurry Fl Krebs Millmax Slurry Pump Item Thomson Process Applications for the millMAX Slurry Pump Mill discharge, crusher slurry, sand and aggregate or any coarse solids or other severe, abrasive slurries especially in the copper, gold, leadzinc, coal, or phosphate plantsiron ore processing mine copper cr alloy rubber slurry Slurry Pumps Xinhai Pump Replacement JXSC Machine The Slurry pump is a kind of centrifugal slurry pump, which is used to convey suspended liquid containing sand, slag and so on The impeller is mostly open The impeller is mostly open The lining of the pump is generally divided into two kinds, the wearresistant metal box, and wearresistant rotary gold wear resistant rubber slurry pump

Production Line Russia Lead Ore Crushing Plant

Root Lead Ore Handling Sand Suction Gravel Pumps Dredging / quarry pumpsour range of dredging / quarry pumps are specifically designed for handling sand, gravel and heavy abrasive slurriesthese centrifugal pumps with closed impellers are robustly constructed using carefully selected materials and unique contour components which offersFlotation Mining Equipment Appropriate Process Technologies Flotation system is based around a group of 6 float cells arranged in a circular tank each individual cell fitted with impellers air spargers and froth launders Host of benefits in the design better mixing in slurry applications resulting in greater efficiency for reactions and a greater uniformity within the tankMineral Processing Equipment Processing The copper ore slurry from the grinding mills is mixed with milk of lime (simply water and groundup limestone) to give a basic pH, pine oil (yes, it comes from trees a byproduct Froth Flotation Process Mineral Processing MetallurgyThe Froth Flotation Process is about taking advantage of the natural hydrophobicity of liberated (well ground froth flotation process use for mining copperGood Quality Gold Silver Flotation Cells Machineflotation Flotation Machine Compared with flotation cells its uniqueness lies in big size lower power loss and light wear and tear of the impeller Flotation machine is commonly used ore flotation equipment in the ore dressing plants and plays a crucial role in the fast development of mining industry in ChinaSilver Flotation Machines Machine In Europa Fixeloadvantages of flotation cell over impact hammer mining Advantages and disadvantages floatation method of separationAdvantages and disadvantages floatation method of separation Productsadvantages of flotation cell over impact hammer mining

- ABOUT RAW MILL CEMENTDUSTRY

- building vibratory feeder ntroler

- small scale gold ore processing machines

- calcite jaw crusher from qatar

- miller manufacturing california molino

- large crushing plant setup

- overview of ash handling system pdf

- granite mine for sale karimnagar

- project on stone crusher

- cement mill liners which material using

- pictures of milling machines

- designing of crusher plant

- electro discharge grinding machine

- grinder koyo model kvd

- manufacture part crusher in SKD

- ep rubber nveyor belt manufacturer

- heavy mining equipment for sale in netherlands antilles

- mining of goldiron and phosphates

- qualified pf1010 impact crusher from china manufacturer (shanghai)

- hammer crusher machine made in germany

- Miningpressor For Sale In China

- operating operating sts for a por le screening plant

- hammer mill crusher definition stone crusher machine

- Vibrating Feeder Working Principle Dip angle

- limited manual user

- chima crusher machine

- mobile manganese ore crusher machine mpany

- orthopaedic grinders and sanders

- calcium carbonate pulverizer and grinding mill for sale

- iron ore crushers manufacturers

- ore processing plants in south africa

- grinder machine in japan

- calculo de molinos de minerales

- Hosokawa Alpine Complete Plant For Calcium Carbonate

- COMERCIAL KINTHEN GRINDER PRICE

- jack hammer and mpressor st crusher south africa

- fortescue iron ore beneficiation technology 2012

- chemical industry manufacturer ultrafine grinding machine price

- australia primary crusher for gold

- Principle Conveyor Mining

Stationary Crushers

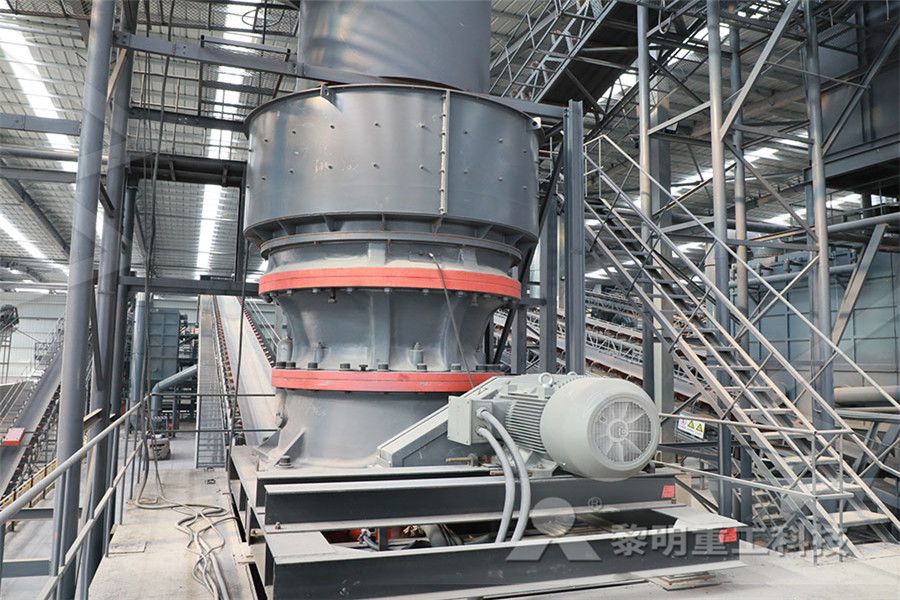

Grinding Mill

VSI Crushers

Mobile Crushers