cement pulverizers material specifications

2023-07-01T19:07:08+00:00

Cement Equipment Product Guidebook NTN Global

Model Number Basic Dynamic Load Rating Basic Static Load Rating Boundary Dimensions Mass Life Ratio kN mm kg 22220B 315 415 ø100×ø180×46 495 1 22217EA 324 330 ø85×ø150×36 259 11 20% 48% 10% Nominal Outside Diameter mm Number of Lubrication Holes D1 Building lime — Definitions, specifications and conformity criteria BS EN 4591 Liming materials — Description and minimum requirements BS EN 14069 Fly ash for concrete Definitions, requirements and quality control BS EN 450 Pulverisedfuel ash Part 1 Specification for pulverisedfuel ash for use with Portland cement Part 2Specifying cement – standards and nomenclature National Standard Material Specifications Chapter 3 (210–VI–NEH, May 2001) 522–1 1 Scope This specification covers the quality of fine aggregate and coarse aggregate for use in the manufacture of portland cement concrete 2 Quality Aggregate shall conform to the requirements of ASTM Specification C 33 for the specified sizes AggregatesMaterial Specification 522—Aggregates for Portland 31 Specifications Most national specifications (uk/mainasp?page=197) for Portland cement require that the cement should not contain more than 5% MgO (less than 3% in the limestone raw material); therefore identification of dolomite is crucial in the evaluation of carbonate rocks for cement manufactureCEMENT RAW MATERIALS CemNetCONCRETE SPECIFICATIONS Materials WATER : Water shall be clean and free from alkaline and acid matters and suitable for drinking purposes CEMENT : shall be fresh Portland cement of standard ISI specifications, and shall have the required tensile and compressive stresses and finenessConcrete Specifications Archinomy

Standard Specification for Portland Cement ASTM

This specification covers eight types of portland cement: type I, type IA, type II, type IIA, type III, type IIIA, type IV, and type V The cement covered by this specification shall only contain the following ingredients: portland cement clinker; water or calcium sulfate, or both; limestone; processing additions; and airentraining addition for airentraining portland cementAre there standard specifications for cements? A Yes The ASTM Standard Specification for Portland Cement (ASTM C150) provides for five types as follows: Type I—The standard product that has long been in use with no limitation on the proportions of the major oxides (CaO, SiO 2, Al 2 O 3, Fe 2 O 3), also referred to as “ordinary portland cement”Standard specifications for cements Concrete Cement and Concrete Institute to investigate the influence of the new SABS EN 1971 cement specifications on the use of cement as a road material stabilizer DISCLAIMER 1 This report is the property of the sponsor and may be published by him provided that: i) The CSIR and its collaborators are acknowledged in the publicationCement stabilization of road pavement materials 1101 (Nov 2016) – Material Specification for Performance Graded Asphalt Cement Table 1 of OPSSMUNI 1101 is deleted in its entirety and replaced with the following: Table 1 – Additional asphalt testing requirements and acceptance criteria for PGAC grades PGAC Grade Property and Attributes (Unit) Test Method Results Reported Rounded to the NearestTS 1101 Material Specification for Performance Graded Cement Cement Cement testing: Various tests to which cements must conform are laid down in national cement specifications to control the fineness, soundness, setting time, and strength of the cement These tests are described in turn Cement Cement testing Britannica

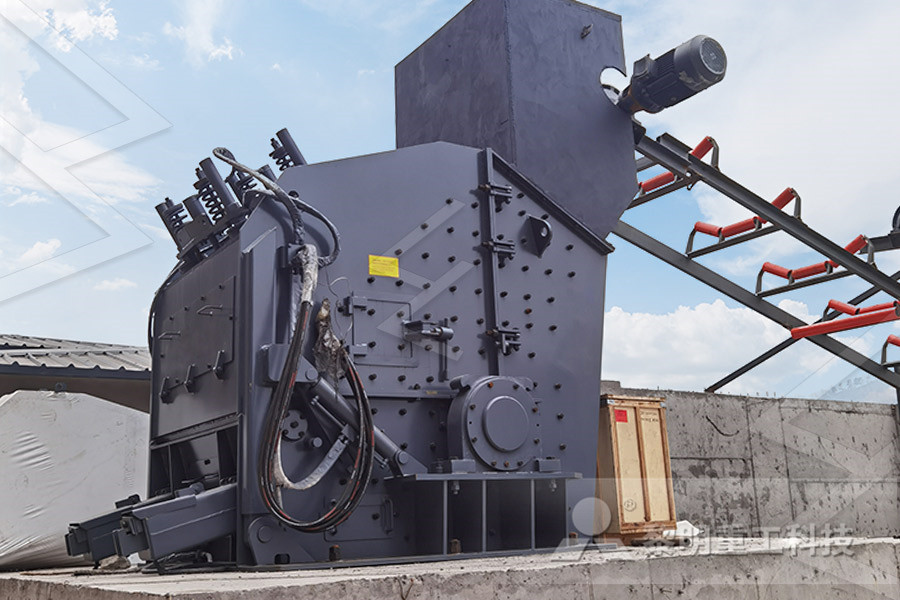

Concrete Crushers, Concrete Pulverizers NPKCE

NPK's Primary/Secondary Concrete Crushers are designed to effectively handle any primary and/or secondary demolition and recycling operation NPK concrete pulverizers easily crush through reinforced concrete and cut through light steel structures allowing material to be separated and recycled, and simultaneously, permits easier handling of materialStandard 60° chute slopes on all models except the SP1 and SP2 improve the material flow of lighter and finer materials while meeting certain coal or coke testing specifications SP1 and SP2 models have 45° chute angles better suited to mineral aggregates SP0 Universal Splitter is built for largevolume bulk aggregate or raw coalcoal pulverizers material specifications InduzinBW is a leading supplier of watertube package and industrial boilers for safe, reliable and uninterrupted plant operation Units are shopassembled or modularized with bottomsupported designs for oil, natural gas and other gaseous and liquid fuelsCement Babcock WilcoxMaterial is picked up by and directed between the roller and ring where it is ground using a combination of attrition and impact Specifications Bradley Pulverizer Screen Mills are available in 2 models based on required output and your specific application needsScreen Mills Bradley Pulverizer CompanyPulverizing is typically defined as 25 mesh and beyond, reducing particles to a powder form to generate the appropriate material engineering for your specifications Learn more about the specific particle size options available with Williams pulverizers and size reduction Pulverizing Machines Pulverizer Machine Manufacturers

Cement Autoclave, Laboratory Cement Autoclave, High

Established in the year 1954, we “Technico Industrial Corporation” are a known firm in this domainOur proficiency lies in manufacturing, supplying, trading and exporting a wide range of Jaw Crushers, Pulverizers, Cement Testing, Bitumen Testing, Aggregate Testing, Soil Testing, General Lab Testing, Metal Testing, Laboratory Testing Material Handling Equipments and many more high grade Cement plants Rather in the raw or finishing mill, cement vertical roller mills are used to grind the raw cement materials to fine particles Coal pulverizers are an integral part to this process NSK in the plant A utility company was in need of a thrust bearing for a gearbox in a tight time frame NSK inspected, quoted, and repaired Bearings for Pulverizers and Vertical Rolling Mills The attached control unit of this Cement Autoclave has a micro processor based PID controller sensitive pressure regulator and gauge, pilot lights and power switches to control the electric heating units inside chamber Specifications:Cement Autoclave Cement Autoclave • The cement industry is very capital intensive Some of the major pieces of equipment include pulverizers, dust collectors, electrostatic precipitators, and rotary kilns • Energy costs can account for up to 40 percent of the total cost of cement manufacturing Currently, over 90 percent of the installed capacity uses coal as the primary fuelAPPLICATION PROFILE Fire Protection TechnologiesAir Preheating Equipment for Cement MachineryRaw Material Chute Dumper Air Slide Blower, Roots Blower, Air Exhauster, Kiln Cooling Fans Air Preheating Equipment for Cement MachineryCalculate Feeder Bowl Pulverizers(Foster Wheeler License) C; Concrete Pump Cement Mills IHI Corporation (Ishikawajima Heavy Industries)

technical specs for pulverizers

Find out more about specifications and technical data of Everdigm EHP 32 starr 2010 in Concrete Pulverizers category Learn more about Everdigm EHP 32 Pulverizers for Cat Excavators are highly effective work tools for processing concrete in a single stepPulverizers Cat Exporter of Cement Testing Equipment Pulverizer, Mortar Mixer, Permeability Tester and Air Permeability Apparatus offered by Central Scientific Instrument Co, Ahmedabad, GujaratCement Testing Equipment Pulverizer Exporter from Product description Autoclaved aerated concrete (AAC)is the material of choice for building applications, such as residential, commercial, industrial and agricultural buildings, hotels, schools and hospitals, etc, an excellent building material for all climatic conditions It is used for all walls, external or internal, loadbearing or nonloadbearing walls, basement walls, infill walls to Industrial Pulverizers Grinding Machines Pulverizing is typically defined as 25 mesh and beyond, reducing particles to a powder form to generate the appropriate material engineering for your specifications Learn more about the specific particle size options available with Williams pulverizers and size reduction Pulverizing Machines Pulverizer Machine

Bearings for Pulverizers and Vertical Rolling Mills

Cement plants Rather in the raw or finishing mill, cement vertical roller mills are used to grind the raw cement materials to fine particles Coal pulverizers are an integral part to this process NSK in the plant A utility company was in need of a thrust bearing for a gearbox in a tight time frame NSK inspected, quoted, and repaired 1Introduction of cement clinker grinding ball mill This series of cement clinker grinding ball mill is suitable for cement, ore dressing, chemical and refractory industry to operate fine grinding , Ltd has become an integrated modern enterprise with scientific research, design, development, manufacturing, sales, installation, commissioning cement mill certificate, cement mill certificate The 3 Major Cement Specifications And Their Cement Types 1 ASTM C150/AASHTO M 85 is a prescriptive specification and lists both the chemical composition required and the physical tests needed to characterize the material ASTM C150 defines ten types of Portland cementCement Testing: Types, Methods Equipment The attached control unit of this Cement Autoclave has a micro processor based PID controller sensitive pressure regulator and gauge, pilot lights and power switches to control the electric heating units inside chamber Specifications:Cement Autoclave Cement Autoclave Development of performancebased material specifications is critical for optimized material use with reduced waste and eventually better utilization of construction dollars From a MEPDG perspective, determining the best use of different qualities of locally available aggregate materials in road bases/subbases may be a challengeChapter Two Aggregate Types and Material

- prices of stone crushers in Nigerian

- stone aggregate quarries

- very hard rock hammer mill

- used stone crushers for sale in mo

- Single Toggle Rock Jaw crusher Pe 400 600

- artificial sand making machine price for india

- how do you apply crusher run gravel

- grinding knives machine

- wood hammer mill for sale in indiana

- send hand sand making machine in india

- ore dressing articles chromite

- ball mill design and different specs

- horizontal grinding mill

- maker of nveyor in cebu

- rotor grinding on micron machines

- ncrete crusher location londres

- how to separate gold from sand with machine

- Used Gold Ore Crusher For Hire In Malaysia

- indian cement mpanies top global valuation chart

- underground transport for gold mining from China

- m design tag archives tempat jual box mika di jogja

- parts for can crusher model

- slag crusher capacity 2000tons

- hollow rivet machine taiwan video

- lombia chancadoras mandibu

- bost crushing equipment in south africa

- art attack mulinos encurva

- what is defective grinder machine

- jaw crushers firstly

- problems solutions crusher

- Designed Of Hydrated Lime Process Machine

- used ore crusher auction

- halite salt ore extraction plant

- calcium carbonate efi group llc

- stone grinding machine manufacturer in china

- impact crusher similar

- sale of heavy scrap crusher

- crushing plant under vat act

- al crushing machine al crushing machine suppliers and

- used nstruction equipment in malaysia

Stationary Crushers

Grinding Mill

VSI Crushers

Mobile Crushers