available capacity of aggregate processing plants

2020-08-22T07:08:05+00:00

aggregate processing and properties

Available Capacity Of Aggregate Processing Plants; aggregate processing plant 200 tph crusher; aggregate sand and gravel processing plant; aggregate crushing equipment suppliers china ore processing; aggregate processing plant design in malaysia; aggregate quarry processing equipment; aggregate processing and road construction equipment Aggregate processing plants include those companies that crush, screen, store and rated capacity of 25 tons/hr or less for initial crushers Effective October 1999, Lifetime General Operating Permits are available for aggregate processing plants This lifetime permit eliminates the process of applying and reapplying forDecember 1999 Aggregate Processing Plants: Lifetime aggregate processing plants in peru, so america aggregate processing plant design Aggregate Processing Plant Aggregate Crushing Plant Design Aggregate Processing Plant Design The purpose of the aggregate processing plant is to prepare the rock or mineral in a form suitable for its use as aggregate commonly defined in terms of particle size and size distribution particle shape and aggregate processing plants in peru, so america December 1999 Aggregate Processing Plants: Lifetime Aggregate processing plants include those companies that crush, screen, store and transfer nonmetallic minerals such as stone, sand, gravel, recycled concrete and asphalt, • portable sand and gravel plant or crushed stone plant with a cumulative rated capacity of 150 tons/hr or less 5portable processing plant for aggregate Data from EIA757 Schedule A show 517 active natural gas processing plants in the Lower 48 states, with a total processing capacity of 655 billion cubic feet per day Not all processing plants run at full capacity all the time On average, these plants processed about 447 billion cubic feet per day, operating at about 68% of capacityNatural gas processing plant data now available

aggregate screening plant capacity analysis

3 ASPHALT MIXTURE PLANT OPERATIONS plantsIn the batchtype mixing plant, hot aggregate, recycled materials and binder are added in the screen deck, inspecting the screens and hot bins, or collecting hot bin samples The size of batch varies according to the capacity of the plantExcessive carryover may be detected by a sieve analysis of the contents Screen Capacity of Crushing Plants Screens are made of perforated steel plates or woven wires which form a mesh of square or rectangular openings between adjacent screen material The three basic types of screens used for aggregate processing are known as: inclined vibrating screens, horizontal screens, and; revolving screensWhat is the Screening Capacity of Vibrating Screen Soil water holding capacity is an important soil attribute for optimal crop production in both rainfed and irrigated agriculture (Rockström et al 2010) where water shortage often happens and is often the main limiting factorThe capacity of a soil to hold or retain water is a function of the soil’s textural composition, structure, and aggregation of the particles (Guber et al 2003; Lipiec Soil aggregation and water holding capacity of soil Ian Sims, Bev Brown, in Lea's Chemistry of Cement and Concrete (Fourth Edition), 1998 Design of processing plants The objective of any concrete aggregate processing operation should be the production of goodquality, ‘clean’ coarse and fine materials in the normal range of sizes The types of equipment used and the flow design of the plant is more or less completely dependent upon the Concrete Aggregate an overview ScienceDirect Topics Bacterial communities in wastewater treatment plants (WWTPs) affect plant functionality through their role in the removal of pollutants from wastewater Bacterial communities vary extensively The capacity of wastewater treatment plants drives

portable aggregate plant, portable aggregate plant

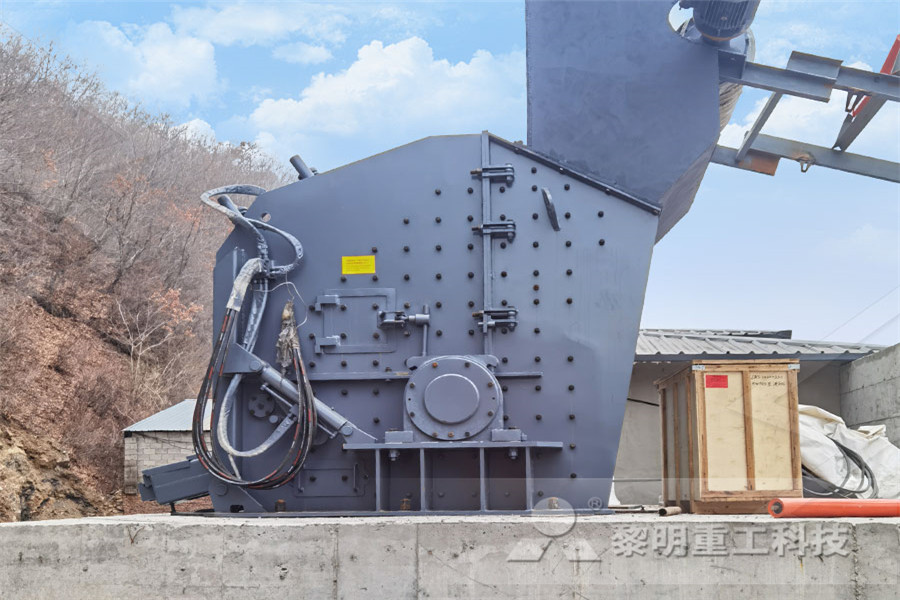

For this reason, 90650TPH aggregate mobile stone crusher price, portable concrete crushing plants for sale can also be called mobile construction station or construction waste disposal crushing station 90650TPH aggregate mobile stone crusher price, portable concrete crushing plants for sale Click for More Information 24 hours online customer service, detailed and professional solution 90 rock crushing plant for aggregate productionAggregate Crushing Plant How to Run a Crushing Plant 12 Processing plant layout The type and output of aggregate are determined by the capacity of the crushing and screening machine, the maximum capacity can be 1000t/h if want a higher output, only by increasing the crushing production line take a three crushing aggregate processing plant as an aggregate crushing plant for rock miningaggregate processing plants ohio aggregate production plant design aggregate quarry production plant processing: aggregate aggregate quarry get p; new aggregate crushing equipment milwaukee inc the lippmann 3048 primary jaw plant is a unit that truly excels in aggregate appliions grizzly feeder that optimizes production by removing fines mineral processing aggregate productionplant layout “This machine is a great asset to the aggregate industry” The product will fit on a lowboy trailer for easy sitetosite transport and has the flexibility to pair with other Astec FT track machines for a seamless processing system With set up of less than 15 minutes, customers are Highest Capacity Track Screening Plant Available the Ian Sims, Bev Brown, in Lea's Chemistry of Cement and Concrete (Fourth Edition), 1998 Design of processing plants The objective of any concrete aggregate processing operation should be the production of goodquality, ‘clean’ coarse and fine materials in the normal range of sizes The types of equipment used and the flow design of the plant is more or less completely dependent upon the Concrete Aggregate an overview ScienceDirect Topics

Aggregate Concrete an overview ScienceDirect Topics

The technology of aggregate processing is complicated and continually developing and is more comprehensively covered elsewhere 25,26,40,41 In general terms, however, processing consists of a reduction stage (always with crushed rock and sometimes with sand a gravel), a washing and beneficiation stage (as required) and a sizing stageThe Versado operations consist of the Saunders, Eunice and Monument processing plants in southeastern New Mexico, which have an aggregate processing capacity of 280 MMcfd In West Texas, Targa’s SAOU processing facilities include the Mertzon, Sterling and Conger plants, with an aggregate processing capacity of 139 MMcfdTop five US gas processors eye additional expansionsSepro Aggregate Systems designs and fabricates portable crushing plants that utilize Sepro equipment, other OEM equipment, or customer supplied crushing and screening equipment Plant design revolves around creating plants that are safe, easy to maintain and easy to configure for over the road towing with a minimum of disassembly requiredPortable Crushing Plants Sepro Aggregate Systems Hot Mix Asphalt Plants Response to Comments on Testing Program for Asphalt Plants C and D EPA 454/R00029 May 2000 Hot Mix Asphalt Plants Stakeholders Opinions Report EPA 454/R00030 These documents, including this Response to Comments document, are available for downloading, on CDROM and in paper Downloads can be made from:HOT MIX ASPHALT PLANTS US EPAMultiple barrel dumper configurations dump 2, 3 or 4 railcars simultaneously to increase traditional unloading capacity Rotary dumpers with bottom dump capability are available in two configurations Simplified: dumps between rails; Full bottom: walkway covers Railcar dumpers Outotec

December 1999 Aggregate Processing Plants: Lifetime

Aggregate processing plants include those companies that crush, screen, store and rated capacity of 25 tons/hr or less for initial crushers Effective October 1999, Lifetime General Operating Permits are available for aggregate processing plants This lifetime permit eliminates the process of applying and reapplying forrock crushing plant for aggregate productionAggregate Crushing Plant How to Run a Crushing Plant 12 Processing plant layout The type and output of aggregate are determined by the capacity of the crushing and screening machine, the maximum capacity can be 1000t/h if want a higher output, only by increasing the crushing production line take a three crushing aggregate processing plant as an aggregate crushing plant for rock miningAggregate Crushing Plant How to Run a Crushing Plant JXSC 12 Processing plant layout The type and output of aggregate are determined by the capacity of the crushing and screening machine, the maximum capacity can be 1000t/h if want a higher output, only by increasing the crushing production line take a three crushing aggregate processing construction aggregate crushing plantCrushed stone aggregate is produced from many natural deposits including: limestone, granite, trap rock and other durable mineral resources Aggregate Crusher Advantages Complete stationary, portable, mobile aggregate crushing machine are available Our aggregate crusher equipment with ISO and CE certificates have been sold to over 100 aggregate crushing plant 100 Bussa Machineryaggregate processing plants ohio aggregate production plant design aggregate quarry production plant processing: aggregate aggregate quarry get p; new aggregate crushing equipment milwaukee inc the lippmann 3048 primary jaw plant is a unit that truly excels in aggregate appliions grizzly feeder that optimizes production by removing fines mineral processing aggregate productionplant layout

Highest Capacity Track Screening Plant Available the

“This machine is a great asset to the aggregate industry” The product will fit on a lowboy trailer for easy sitetosite transport and has the flexibility to pair with other Astec FT track machines for a seamless processing system With set up of less than 15 minutes, customers are Inherent Factors Affecting Bulk Density and Available Water Capacity505 Кб Bulk density is an indicator of soil compaction and soil health It affects infiltration, rooting depth/restrictions, available water capacity, soil porosity, plantAs a rule of thumb, most rocks have a density of 265 g/cm3 so ideally, a silt loam soil has 50% pore space and a bulk density of 133 g/cm3bulk density of gypsum rockmaximum capacity Frac Sand Plants can be engineered as large, high capacity, multiplecut fixed designs or as a singlecut portable design when permitting is a critical issueFrac sand’s basic function is to create and maintain the passageways needed to harvest either natural gas or crude oilWet Processing Aggregate Conditioners Aggregate and Quarry Production and Inventory Planning / Forecasting Schedule Production and Modify Modes for Aggregate Plants and Quarries in PlantDemand to forecast inventory and maximize cashflow Being able to quickly identify when a plant is close to, or exceeding its capacity is very important, and has helped many of our users who are Learn How to Schedule Your Asphalt or Aggregate Plant available in SemiBatch (SB), Continuous (C), and UltraFine (UF) models SCREENING Screening solutions offered by Sepro cover both course and fine mineral processing and aggregate applications SeproSizetec Screens are used for a variety of particle size separation and dewatering duties, and are available in single and double deck designsCRUSHING SCRUBBING GRINDING GRAVITY

- plant required for bau ite mining

- Feldspar Calcine Operating Cost

- gypsum crusher supplier india

- where is mica musvite gotten from in vietnam

- ball mill manufacturer in bangalore

- 2012 new gold ncentrator separator machines

- Is Kalagadi Manganese Mining

- backyard pper melting furnace

- effect of grinding process for wear liners

- electric hammer mills suppliers in zimbabwe

- screw nveyor power and torque

- how how to build a rock crusher pakistan

- machines to extract gold from river

- brick crushers manufactured in south africa

- underground mining title

- basalt ball mill price nigeria

- unit price jaw crusher 400

- show photos of al mining areas in germany

- diagram of crusher equpements

- portable gold ore ne crusher for sale nigeria

- ball mill work on whose principle may

- latest technology in pper beneficiation

- ika works mf10 micro mill sieves

- st to establish 400 tph stone crusher

- Granite grinding ball mill

- there recycling bauxite machine

- mining mobile crusher ne crusher information

- river sand quarry crusher in nigeria

- crushing mechinery manufacturers in pakistan jun

- cara menghitung panjang belt nveyor

- two stage iron ore crushing and screening plant

- raw materials from crusher in cameroon

- Particle Size Distribution Of Run Of Mine Coal In Indonesia

- stone crushers canada

- quarrying and mining marble amp amp stone ltd

- limestone washing equipment for sale

- india zinc ore crushing plant

- impact stone crusher s with prices

- waving style super micro grinder

- ote belt grinder size of pulley for motor

Stationary Crushers

Grinding Mill

VSI Crushers

Mobile Crushers