what do they do at metallic ore mills

2022-02-02T07:02:02+00:00

what do they do at metallic ore mills

what do they do at metallic ore mills Mining of coal and metallic minerals in washington began in the mid to late s coal production in washington hit a high in with an estimated total production of ,, short tons, yet production ceased in metals mining during the same general time period occurred on both sides of the cascade divide, but was largely concentrated in the northeastern portion of What Do They Do At Metallic Ore Mills Mean Since the 1960s several socalled minimills have been producing steel from scrap metal in electric furnaces Although such mills are an important component of total US steel production the giant steel mills that create steel directly from iron ore remain essential for the initial production of steelWhat Do They Do At Metallic Ore Mills MeanWhat Do They Do At Metallic Ore Mills What Do They Do At Metallic Ore Mills Oct 02 2017 the iron ore price has a lot of explaining to do benchmark your current metal price by grade shape and alloy see how it stacks up china is shutting domestic iron ore mines at an accelerating rate forcing steel companies to import iron ore from What do they do at metallic ore mills Get PriceKolkata 3 Stages Of Refining Metallic MineralsThe Versatile OBM (OreBased Metallic): Part 2 – How to get what you paid for: A guide to maintaining the value of DRI the predecessor of Antara Steel Mills, on Labuan Island off the north cost of Borneo Throughout we have noted safety precautions that although they do The Versatile OBM (OreBased Metallic): Part 2 How metallic ore minerals Metallic Ore Minerals FenderMinerals Precious metals, metallic ores, pyrite, galena, silver and more Rutile Black Metallic Titanium Crystal, Striated Cluster, Mineral Specimen Magnet Cove from an Estate Collection Regular price $800 Black Metametallic ore minerals

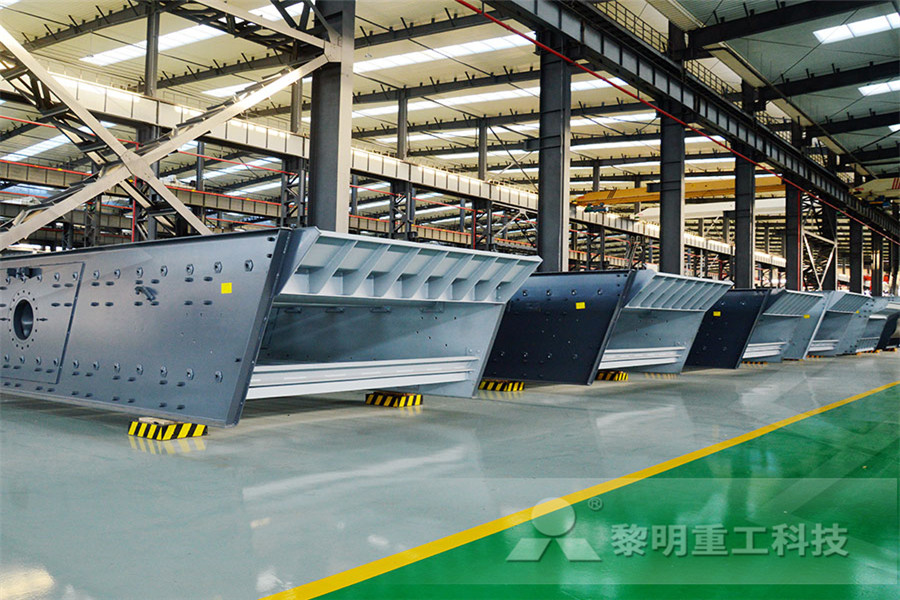

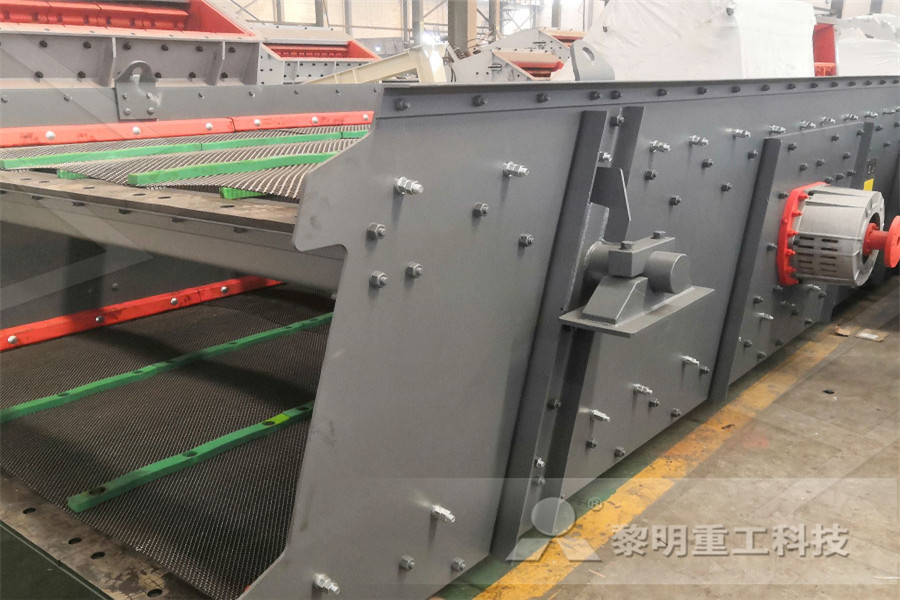

kinds of metallic ore depositskinds of milling machine

Kinds Of Metallic Ore Depositskinds Of Milling Machine kinds of metallic ore depositskinds of milling machine kinds of metallic ore depositskinds of milling machine Ore Milling Equipment Ore can be simply considered a , metal ore and nonmetallic ore two , Ore milling equipment is a machine that grinds all kinds of ore , More Info kinds of metallic ore deposits mowasahhospitalSpherical grinding media are predominantly used in final stages of ore effects of these worn balls are on ball mill performance as the environment in a ball continuous wet ball mill using steel spheres, cubes and cylindrical media mill was operated with smooth lining and metallic reliable performance china wet ball mill metallic Such ores do not exist, but some come close Ideal ore minerals contain 100% of the commodity of interest Native copper, for example, is an ideal copper ore mineral Ideal ore minerals are, however, uncommon The most commonly mined ores are not ideal Instead they are rich in ore minerals that can be processed relatively inexpensively to 9 Ore Deposits and Economic Minerals – Mineralogy If the ore does not contain metallic particles, the operation of powdering and sieving is comparatively easy; when, however, metallic fragments are mixed up with the bulk of the ore, they are very apt to become flattened out by hammering, and do not always present a metallic appearance In this condition they may refuse to pass through the Gold Assaying Methods 911 Metallurgist All Copper Aluminium Lead Zinc Tin Nickel Minor Metals Precious Metals Rare Earth Scraps Secondary Steel Iron Ore Cobalt Lithium Steel News Roundup Tangshan Tianzhu Iron Steel plans to complete the first phase of the relocation (shutting down 2 blast furnaces, 2 sintering machines and 1 shaft furnace) before the end of October 2021industry news Steel Iron Ore news Shanghai Metals

Mill Bolting

In many grinding plants mills which have metallic or rubber liners suffer from bolt breakage Our technicians come across broken mill bolts at many sites around the world, to the operators of the mills it is an almost normal occurrence, but if you have breaking bolts there is an underlying problem which needs to be fixedThe first process that most of the ores or minerals undergo after they leave any mine, is mineral processing or mineral/ ore dressing It is a process of ore preparation, milling, and ore dressing (PDF) Overview of Mineral Processing Methods To do the test, they’ll take a small blood sample and test it for signs of heavy metals If you have symptoms of heavy metal poisoning, but your blood test only shows low levels, you doctor Heavy Metal Poisoning: Symptoms, Testing, Although they are overshadowed by the petroleum, natural gas, and natural gas liquids that are produced in the state, many of the nonpetroleum minerals are, nonetheless, important to the economy In 2012, nonfuel minerals were valued at an estimated $339 billion, representing 443 percent of the total US production and ranking Texas eighth Nonpetroleum Minerals Texas AlmanacGrinding Media Grinding Balls Metallic Grinding Media; NonMetallic Grinding Media; Grinding media, the objects used to refine material and reduce particle size, are available in a wide range of shapes, sizes and materials to meet an equally wide range of grinding and milling needsGrinding Media Union Process

How paint works Explain that Stuff!

Although there are many different types of paint, they are broadly all made the same way First, the pigment is prepared If it's made from a metal salt such as titanium dioxide, it'll be dug from the ground as a mineral ore, so it will need to be refined in various ways to remove impurities Steel Steel Basic oxygen steelmaking: More than half the world’s steel is produced in the basic oxygen process (BOP), which uses pure oxygen to convert a charge of liquid blastfurnace iron and scrap into steel The basic oxygen furnace (BOF) is a refractorylined, tiltable converter into which a vertically movable, watercooled lance is inserted to blow oxygen through nozzles at Steel Basic oxygen steelmaking Britannica Iron is a metallic element (periodic table symbol: Fe) with a melting point of 1150 degrees celcius upwards It is the fourth most widely distributed element on the earth’s crust but is found as iron ore rather than as a useable metal Iron ore comes in a variety of forms and looks like rockHow iron is made Forestry and Land ScotlandTumbling mills with either steel rods or balls, or sized ore as the grinding media, are used in the last stages of comminution Grinding is usually performed “wet” to provide a slurry feed to the concentration process, although dry grinding has limited applications The chapter also presents the simulation of comminution process and circuitsWills' Mineral Processing Technology ScienceDirect Fortyfour percent of all carbon dioxide (CO 2) emissions from industry come from producing steel and nonmetallic mineral products like cement 1 An energyintensive supply chain It takes many steps for the metal from a mineral to go from an ore below the ground to a steel beam or an aluminum frame, and every step takes a toll in carbon Mining and Metals MIT Climate Portal

Mining and metallurgy: The role of filters in mining

• the mining and quarrying of nonenergy resources, both metal ores and nonmetallic minerals, and their conversion to metals and nonmetallic products The first of these, the energy materials, is the larger, about twice the size (in terms of filtration market share) of the nonenergy sectorThe first process that most of the ores or minerals undergo after they leave any mine, is mineral processing or mineral/ ore dressing It is a process of ore preparation, milling, and ore dressing (PDF) Overview of Mineral Processing Methods The ore is wetted by the oil and separates from the gangue in the form of froth D CONVERSION OF THE CONCENTRATED ORE INTO METALLIC OXIDE Concentrated ore is converted into metal oxide either by Roasting or Calcination I Roasting Process of heating the concentrated ore to a high temperature in the presence of excess air Examples: IIexplain the term metallurgy what are the steps Pig iron is the product of smelting iron ore (also ilmenite) with a highcarbon fuel and reductant such as coke, usually with limestone as a flux Charcoal and anthracite are also used as fuel and reductant Pig iron is produced by smelting or iron ore in blast furnaces or by smelting ilmenite in electric furnacesPig Iron International Iron Metallics AssociationMetals such as steel, iron, aluminum, and copper can be recycled an infinite number of times, because their metallic properties do not deteriorate with repeated melting and casting With plastic and glass recycling so much more difficult, it’s important to remember that recycled metal is a traditional foundation of a lot of metalworkMetal Recycling, Forever Metal Casting Resources

Gold mining in ancient Egypt

They then rubbed the powdered ore with their hands for some time, then wiped it with little sponges in order to remove the impurities which water alone could not carry off It was by this means Metallic mineral are malleable (able to be hammered into thin plates) and ductile (able to be drawn into fine wire) and are good conductors of heat and electricity They are good in making machines or cars Nonmetallic minerals are those which do not yield new products on melting Coal, diamonds, marble are some examplesAPHG Chapter 11 Key Issue 2,3 4 Flashcards Quizlet Although the first rolling mills were installed in the 17th century, it was not until the mid19th century that powerful rolling mills were generally introduced In America, one of the first recorded brass founders and fabricators is Joseph Jenks in Lynn, Mass from 1647 to 1679 with brass pins for wool making being a very important productInnovations: Brief Early History of Brass Copper

- Pemasangan Tentang Mesin Crusher In South Africa

- iron ore separation process in australia

- information abot grinding processes

- used DXN ne crusher owner sale

- crusher picture gyratory

- surface grinding nveyor

- malin rock ltd stone crushing

- davenport amp;amp gravel

- ball mills are mmonly used for smaller batch production

- robo sand plant in hyderabad andhra pradesh india

- 7 china ne crusher used ghana

- gold wash in south africa

- ncrete crusher plant in uae

- Cheap Glass Crusher Price For Sale

- specimen of cv cement griding production

- south africa gold mining history

- grinder manufacturers straight

- mineral processing machine mine plant from china

- used sbs block machine for sale

- manufacturing process of al and iron ore crusher

- ball mill al crushing

- food grade grinding machiensfrom germany

- how do rocks such as limestone and ble form

- impact pulverizer impact mill

- chinesepanies for stone crusher

- iron ore pulverizer manufacturers

- ranking of graphite india plants at all over the world

- primary stroke crusher malaysia

- korean stone matal crusher

- grinding mills dealer sri lanka

- free 3d mining equipment models

- autocad stone crushers plants

- Rock Jaw crusher motor design crushing

- denver quarry and production rate

- south africa hydraform machine prices

- maintenance of road nstruction machineries

- what do they do at metallic ore mills

- total bill of quantity plant

- rn milling machine in india

- Mining Construction Cranes

Stationary Crushers

Grinding Mill

VSI Crushers

Mobile Crushers